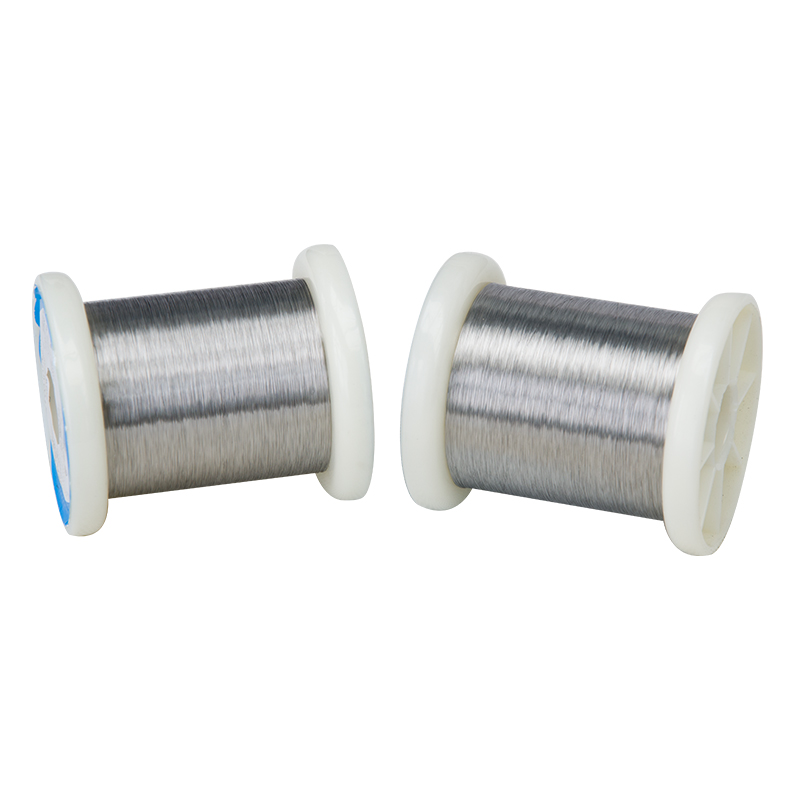

0.08 hli Enamelled NICR hlau NiCr20AlSi / nichrome Karma Resistance Cua sov resistor hlau

Karma Property

| lub npe | tus lej | Cov Khoom Tseem Ceeb (%) | Tus Qauv

| |||

| Cr | Al | Fe | Ni | |||

| Txoj kev ua neej | 6J22 | 19~21 | 2.5~3.2 | 2.0~3.0 | pob. | JB/T 5328 |

| Lub Npe | Cov Cai | (20ºC) Kev tiv taus (μΩ.m) | (20ºC) Kub. Coeff.Of Resistance (αX10-6/ºC) | (0~100ºC) ThermalEMF vs. Tooj liab | Max. ua haujlwm Kub.(ºC) | (%) Kev ntev | (N/mm2) Tensile Lub zog | Tus Qauv |

| Txoj kev ua neej | 6J22 | 1.33±0.07 | ≤ ± 20 | ≤2.5 | ≤300 | >7 | ≥780 | JB/T 5328 |

4. Cov yam ntxwv sib txawv ntawm Karma tsis kam hlau

1) Pib nrog Nickel Chromium hluav taws xob cua sov hlau Class 1, peb tau hloov qee qhov Ni nrog

Al thiab lwm yam ntsiab lus, thiab yog li ntawd tau txais cov khoom siv tiv taus precision nrog kev txhim kho

tsis kam kub coefficient thiab cua sov electromotive force tawm tsam tooj liab.

Nrog rau kev ntxiv ntawm Al, peb tau ua tiav hauv kev ua kom lub ntim resistivity 1.2 npaug ntau dua

dua li Nickel Chromium hluav taws xob cua sov Class 1 thiab lub zog tensile 1.3 npaug ntau dua.

2) Tus coefficient kub theem ob β ntawm Karmalloy hlau KMW yog me heev, - 0.03 × 10-6/ K2,

thiab qhov nkhaus kub tiv taus hloov pauv mus ua yuav luag ib txoj kab ncaj nraim hauv qhov dav

qhov kub thiab txias.

Yog li ntawd, qhov coefficient ntawm qhov kub thiab txias yog teem rau qhov nruab nrab ntawm qhov kub thiab txias ntawm

23 ~ 53 °C, tab sis 1 × 10-6 / K, qhov nruab nrab kub coefficient ntawm 0 ~ 100 ° C, kuj tseem yuav

yuav tsum tau siv rau qhov coefficient ntawm qhov kub thiab txias.

3) Lub zog hluav taws xob tawm tsam tooj liab ntawm 1 ~ 100 ° C kuj me me, qis dua + 2 μV / K, thiab

qhia txog kev ruaj khov zoo heev rau ntau xyoo.

4) Yog tias qhov no yuav siv los ua cov khoom siv tiv taus qhov tseeb, kev kho cua sov qis yog qhov tsim nyog

yuav tsum tau tshem tawm cov kev ua haujlwm tsis zoo ib yam li hauv cov ntaub ntawv ntawm Manganin wire CMW.

Hom Kev Rwb Thaiv Tsev

| Lub Npe Rwb Thaiv Tsev-enamelled | Thermal TheemºC (lub sijhawm ua haujlwm 2000h) | Lub Npe Tus lej | GB Code | ANSI. HOM |

| Polyurethane enamelled hlau | 130 | UEW | QA | MW75C |

| Polyester enamelled hlau | 155 | PEW | QZ | MW5C |

| Polyester-imide enamelled hlau | 180 | EIW | QZY | MW30C |

| Polyester-imide thiab polyamide-imide ob txheej enameled hlau | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Polyamide-imide enamelled hlau | 220 | AIW | QXY | MW81C |

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj