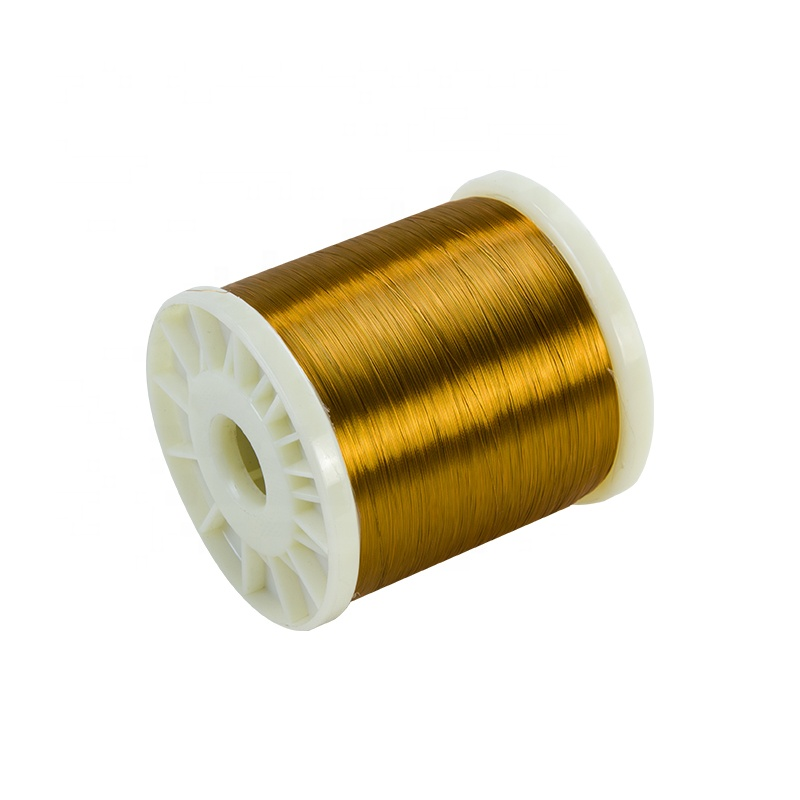

0.2 hli 130 Chav Kawm Enameled Hlau Xim Round Tooj Liab Alloy Manganin

130 Chav Kawm Xim Puag Ncig Tooj Liab Alloy Manganin Enameled Hlau

1. Cov Khoom Siv Piav Qhia Dav Dav

Tooj liab nickel alloy, uas tsis tshua muaj hluav taws xob tiv taus, zoo tiv taus kub thiab tiv taus xeb, yooj yim rau kev ua thiab ua cov hlau lead welded. Nws yog siv los ua cov khoom tseem ceeb hauv thermal overload relay, tsis tshua muaj kev tiv taus thermal circuit breaker, thiab cov khoom siv hluav taws xob. Nws kuj yog ib qho khoom siv tseem ceeb rau hluav taws xob cua sov cable. Nws zoo ib yam li s hom cupronickel. Yog tias muaj Nickel ntau npaum li cas, qhov saum npoo yuav dawb dua.

3. Cov Tshuaj Lom Zem thiab Cov Khoom Tseem Ceeb ntawm Cu-Ni Low Resistance Alloy

| Cov Khoom Qib | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuMn3 | CuNi10 | |

| Cov Tshuaj Lom Zem Tseem Ceeb | Ni | 1 | 2 | 6 | 8 | _ | 10 |

| Mn | _ | _ | _ | _ | 3 | _ | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Qhov Kub Tshaj Plaws Kev Pabcuam Txuas Ntxiv Mus (oC) | 200 | 200 | 200 | 250 | 200 | 250 | |

| Kev tiv taus ntawm 20oC (Ωmm2 / m) | 0.03 | 0.05 | 0.10 | 0.12 | 0.12 | 0.15 | |

| Qhov Ceev (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.8 | 8.9 | |

| Kev Ua Kub (α × 10-6 / oC) | <100 | <120 | <60 | <57 | <38 | <50 | |

| Lub zog tensile (Mpa) | ≥210 | ≥220 | ≥250 | ≥270 | ≥290 | ≥290 | |

| EMF vs Cu (μV / oC) (0 ~ 100oC) | -8 | -12 | -12 | -22 | _ | -25 | |

| Kwv yees li ntawm Melting Point (oC) | 1085 | 1090 | 1095 | 1097 | 1050 | 1100 | |

| Cov Qauv Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Khoom Siv Sib Nqus | tsis yog | tsis yog | tsis yog | tsis yog | tsis yog | tsis yog | |

| Cov Khoom Qib | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNi44 | |

| Cov Tshuaj Lom Zem Tseem Ceeb | Ni | 14 | 19 | 23 | 30 | 34 | 44 |

| Mn | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Cu | Bal | Bal | Bal | Bal | Bal | Bal | |

| Qhov Kub Tshaj Plaws Kev Pabcuam Txuas Ntxiv Mus (oC) | 300 | 300 | 300 | 350 | 350 | 400 | |

| Kev tiv taus ntawm 20oC (Ωmm2 / m) | 0.20 | 0.25 | 0.30 | 0.35 | 0.40 | 0.49 | |

| Qhov Ceev (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | |

| Kev Ua Kub (α × 10-6 / oC) | <30 | <25 | <16 | <10 | <0 | <-6 | |

| Lub zog tensile (Mpa) | ≥310 | ≥340 | ≥350 | ≥400 | ≥400 | ≥420 | |

| EMF vs Cu (μV / oC) (0 ~ 100oC) | -28 | -32 | -34 | -37 | -39 | -43 | |

| Kwv yees li ntawm Melting Point (oC) | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | |

| Cov Qauv Micrographic | austenite | austenite | austenite | austenite | austenite | austenite | |

| Khoom Siv Sib Nqus | tsis yog | tsis yog | tsis yog | tsis yog | tsis yog | tsis yog | |

2. Kev Taw Qhia thiab Daim Ntawv Thov ntawm Enamelled Wire

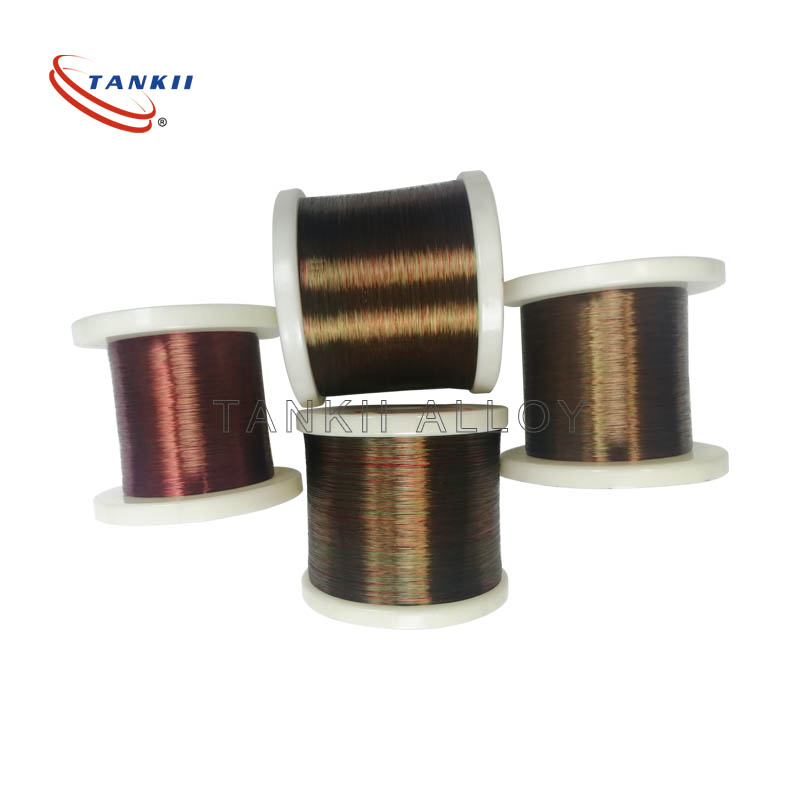

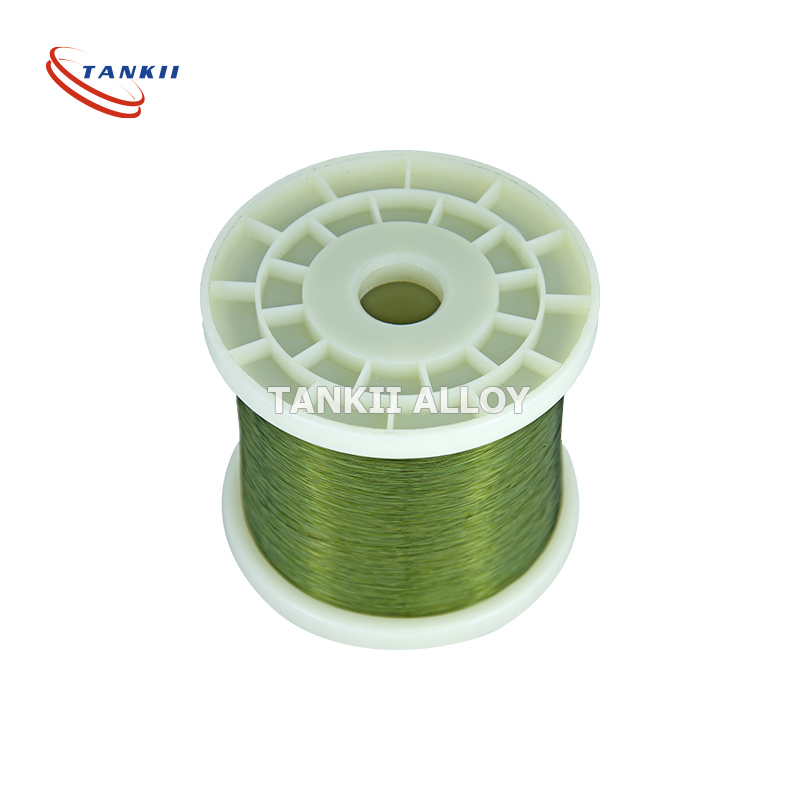

Txawm hais tias piav qhia tias yog "enameled",hlau enameledQhov tseeb, tsis yog coated nrog ib txheej ntawm enamel xim los yog nrog vitreous enamel ua los ntawm fused iav hmoov. Niaj hnub nimno magnet hlau feem ntau siv ib mus rau plaub txheej (nyob rau hauv cov ntaub ntawv ntawm quad-zaj duab xis hom hlau) ntawm polymer zaj duab xis rwb thaiv tsev, feem ntau ntawm ob qho sib txawv, los muab ib tug tawv, txuas ntxiv insulating txheej. Magnet hlau insulating zaj duab xis siv (nyob rau hauv kev txiav txim ntawm nce kub ntau yam) polyvinyl formal (Formar), polyurethane, polyimide, polyamide, polyster, polyester-polyimide, polyamide-polyimide (los yog amide-imide), thiab polyimide. Polyimide insulated magnet hlau muaj peev xwm ua haujlwm ntawm txog li 250 ° C. Lub rwb thaiv tsev ntawm tuab square lossis rectangular magnet hlau feem ntau yog augmented los ntawm kev qhwv nws nrog ib tug kub siab polyimide lossis fiberglass daim kab xev, thiab tiav windings feem ntau yog nqus tsev impregnated nrog ib tug insulating varnish los txhim kho lub zog rwb thaiv tsev thiab ntev kev ntseeg siab ntawm lub winding.

Cov kauj uas txhawb nqa tus kheej yog qhwv nrog cov hlau coated nrog tsawg kawg yog ob txheej, sab nraud tshaj plaws yog cov thermoplastic uas khi cov tig ua ke thaum cua sov.

Lwm hom rwb thaiv tsev xws li cov xov fiberglass nrog cov kua roj vanish, ntawv aramid, ntawv kraft, mica, thiab zaj duab xis polyester kuj siv dav thoob plaws ntiaj teb rau ntau yam kev siv xws li transformers thiab reactors. Hauv kev lag luam suab, cov hlau nyiaj tsim, thiab ntau yam insulators, xws li paj rwb (qee zaum permeated nrog qee yam coagulating agent / thickener, xws li beeswax) thiab polytetrafluoroethylene (PTFE) tuaj yeem pom. Cov ntaub ntawv rwb thaiv tsev qub suav nrog paj rwb, ntawv, lossis silk, tab sis cov no tsuas yog siv tau rau cov ntawv thov qis-kub (txog li 105 ° C).

Rau qhov yooj yim ntawm kev tsim khoom, qee cov hlau nplaum qib qis-kub muaj cov rwb thaiv tsev uas tuaj yeem tshem tawm los ntawm cua sov ntawm kev sib txuas. Qhov no txhais tau tias kev sib txuas hluav taws xob ntawm qhov kawg tuaj yeem ua tau yam tsis tas yuav tshem tawm cov rwb thaiv tsev ua ntej.

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj