Txais tos rau peb cov vev xaib!

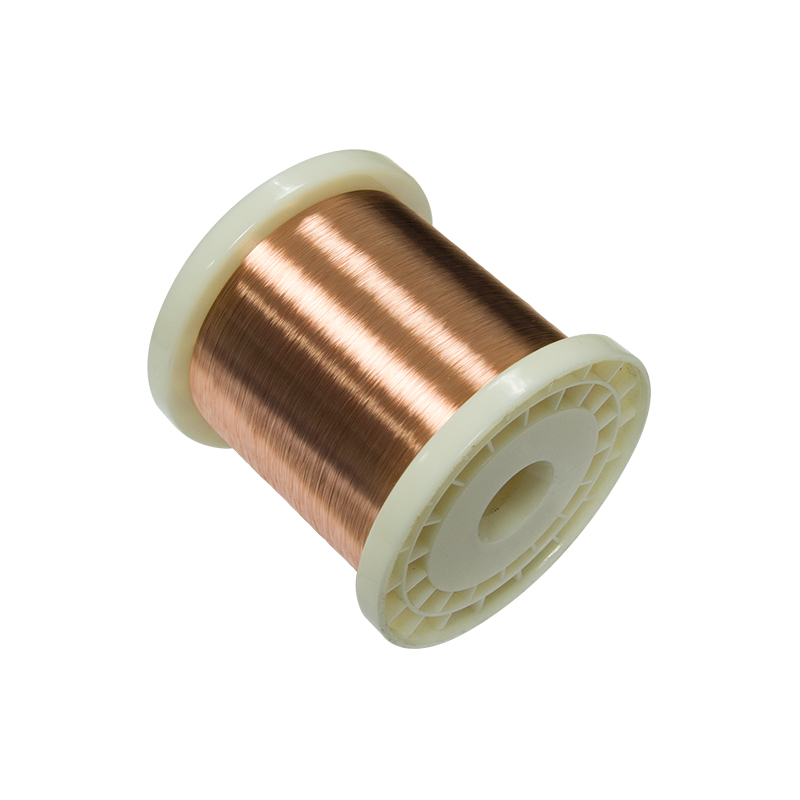

1.2mm/1.6mm/2.0mm Tafa 70t Metco Praxair Monel 400 K500 Hlau rau Thermal Tsuag

Monel 400yog ib qho hlau nickel-tooj liab (kwv yees li 67% Ni - 23% Cu) uas tiv taus dej hiav txwv thiab pa dej ntawm qhov kub siab nrog rau ntsev thiab cov kua caustic. Alloy 400 yog ib qho hlau khov kho uas tsuas yog tuaj yeem ua kom tawv los ntawm kev ua haujlwm txias. Cov hlau nickel no qhia txog cov yam ntxwv zoo li kev tiv thaiv corrosion zoo, weldability zoo thiab lub zog siab. Tus nqi corrosion qis hauv cov dej ntws sai lossis dej hiav txwv ua ke nrog kev tiv thaiv zoo heev rau kev ntxhov siab-corrosion tawg hauv feem ntau cov dej tshiab, thiab nws txoj kev tiv thaiv rau ntau yam kev mob corrosive ua rau nws siv dav hauv kev siv marine thiab lwm yam kev daws teeb meem tsis-oxidizing chloride.

Cov ntawv thov:

* Cov li qub, cov twj tso kua mis, cov ncej, cov khoom siv, thiab cov khoom siv txuas

* Cov khoom siv hloov pauv cua sov

* Cov kuab tshuaj chlorine

* Cov pej thuam roj av

* Cov khoom siv hloov pauv cua sov

* Cov kuab tshuaj chlorine

* Cov pej thuam roj av

* Kev tsim kho dej hiav txwv

* Cov khoom siv ua tshuaj lom neeg thiab hydrocarbon

* Cov thoob roj av thiab cov thoob dej tshiab

* Cov roj av Crude

* Cov cua sov uas tshem cua

* Cov cua sov dej pub rau boiler thiab lwm yam kev sib pauv cua sov

* Cov khoom siv ua tshuaj lom neeg thiab hydrocarbon

* Cov thoob roj av thiab cov thoob dej tshiab

* Cov roj av Crude

* Cov cua sov uas tshem cua

* Cov cua sov dej pub rau boiler thiab lwm yam kev sib pauv cua sov

| Cov Tshuaj Lom Zem | |||||||

| Qib | Ni% | Cu% | Fe% | Mn% | C% | Si% | S% |

| Monel 400 | Yam tsawg kawg nkaus 63 | 28-34 | Siab tshaj plaws 2.5 | Siab tshaj 2.0 | Qhov siab tshaj plaws yog 0.30 | Siab tshaj plaws 0.50 | Qhov siab tshaj plaws 0.024 |

| Monel 400 Hom Thoob Ntiaj Teb | ||||

| Tebchaws Meskas | GE | UK | FR | |

| UNS | SEW VDIUV | BS | AFNOR | |

| Monel 400 | N04400 | W.Nr.2.4360 NiCu30Fe | NA 12 | Nu 30 |

| Cov Khoom Siv Lub Cev | ||

| Qib | Qhov Ceev | Qhov Kub Yaj |

| Monel 400 | 8.83 g/cm3 | 1300ºC-1390ºC |

| Cov Khoom Siv Kho Tshuab | ||||

| Cov hlau nplaum | Lub zog tensile (Rm N/mm2) | Lub zog tawm los (RP0.2N/mm2) | Kev ntev (A5%) | HB |

| Monel 400 | 480 | 170 | 35 | ≥331 |

| Tus Txheej Txheem Tsim Khoom | |||||

| Bar | Kev ntaus nrig | Yeeb Nkab | Daim Ntawv/Stripe | Hlau vuam | |

| Tus Qauv | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ERNiCu-7 |

Lwm Cov Hlau Tshuaj Txau Thermal

| Khoom | Cov ntsiab lus tshuaj lom neeg | Zn | Cd | Pb | Fe | Cu | Tag Nrho Cov Nyiaj Tshuav |

| zinc ntshiab | Tus nqi nominal | ≥99.995 | ≤0.002 | ≤0.003 | ≤0.002 | ≤0.001 | 0.005 |

| Khoom | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel 500 | HC-276 | Cr20Ni80 |

| C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

| Fe | ≤1.0 | Tsis muaj | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | Tsis muaj |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

| Cu | Tsis muaj | Tsis muaj | Tsis muaj | so | 27-33 | Tsis muaj | Tsis muaj |

| Ni | so | so | so | 65-67 xyoo | so | so | so |

| Co | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj |

| Al | ≤0.4 | 4-5 | Tsis muaj | ≤0.5 | 2.3-3.15 | Tsis muaj | Tsis muaj |

| Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | Tsis muaj | Tsis muaj |

| Cr | 21.5-23 | ≤0.2 | 42-46 | Tsis muaj | Tsis muaj | 14.5-16 | 20-23 |

| Nb | 3.5-4.15 | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj | ≤1.0 |

| Mo | 8.5-10 | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj | 15-17 | Tsis muaj |

| V | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj | ≤0.35 | Tsis muaj |

| W | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj | Tsis muaj | 3.0-4.5 | Tsis muaj |

| Cov Khoom Tsis Huv | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

3. C276hlau tsuag thermal

Cov Npe Feem Ntau: Oxford Alloy® C-276 FM C-276 Techalloy 276

Standard: AWS A5.14, ERNiCrMo-4/ASME II, SFA-5.14, UNS N10276 Werkstoff Nr. 2.4886 ISO SNi6276 Teb chaws Europe NiCrMo16Fe6W4

TSHUAJ TXHUAM TXHEEJ (%)

| C | Si | Mn | S | P | Ni | Co |

| ≤0.02 | ≤0.08 | ≤1.0 | ≤0.03 | ≤0.04 | So | ≤2.5 |

| W | V | Fe | Cu | Cr | Mo | lwm tus |

| 3.0-4.5 | ≤0.35 | 4.0-7.0 | ≤0.5 | 14.5-16.5 | 15-17 | <0.5 |

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj