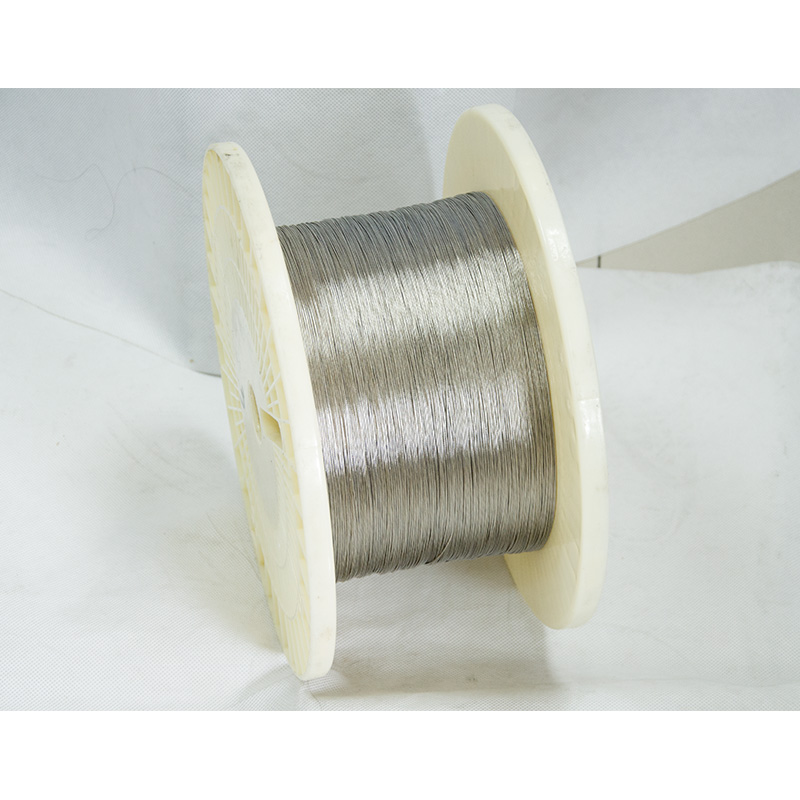

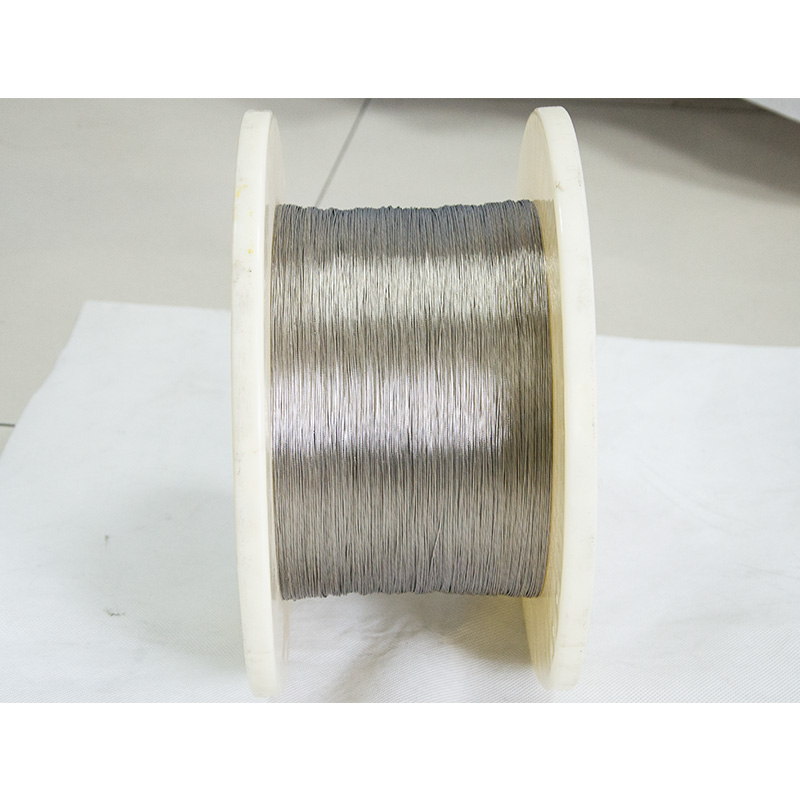

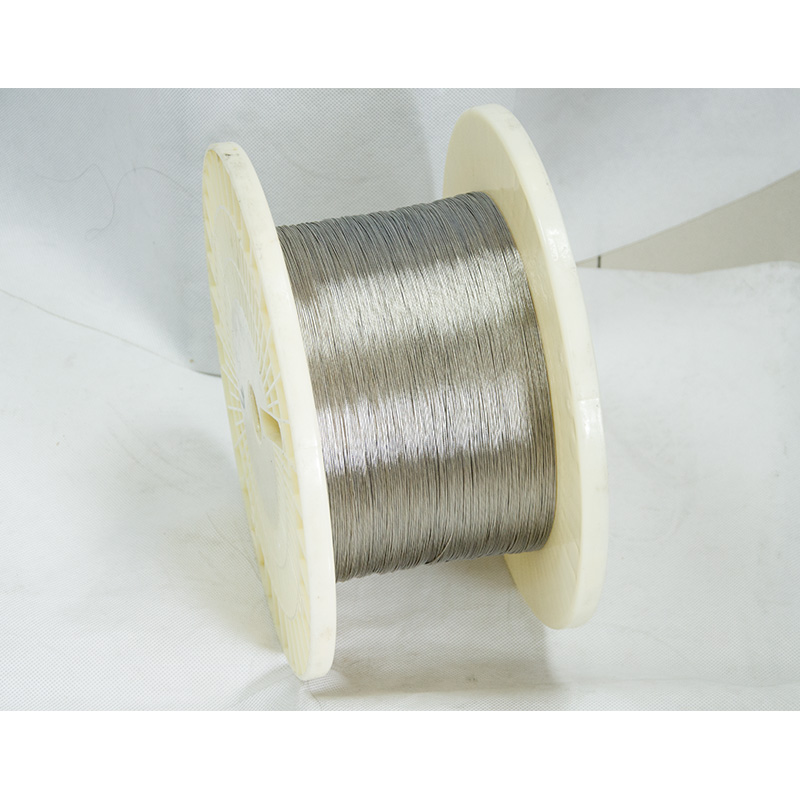

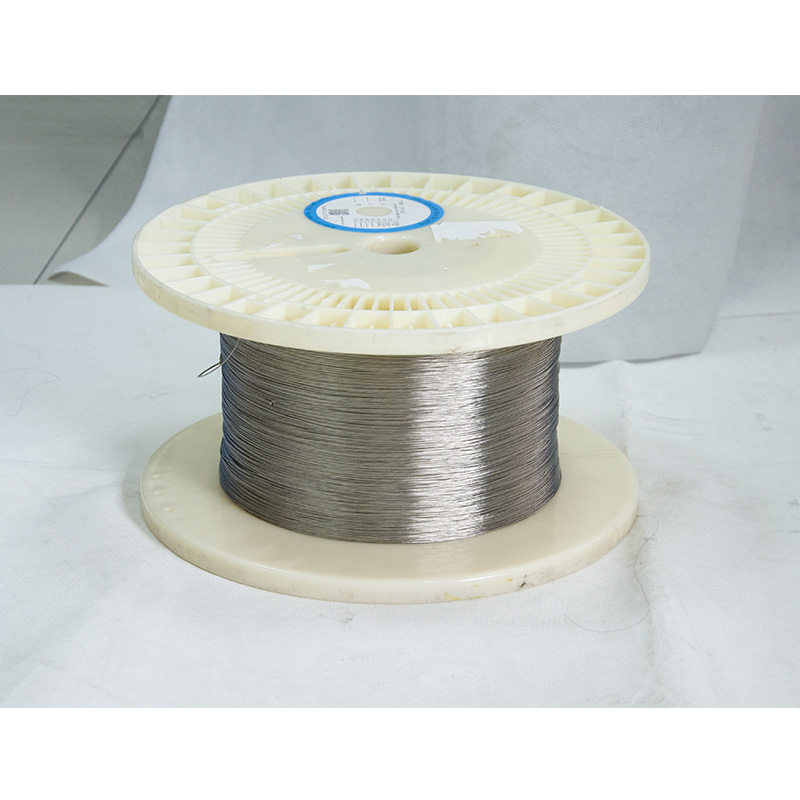

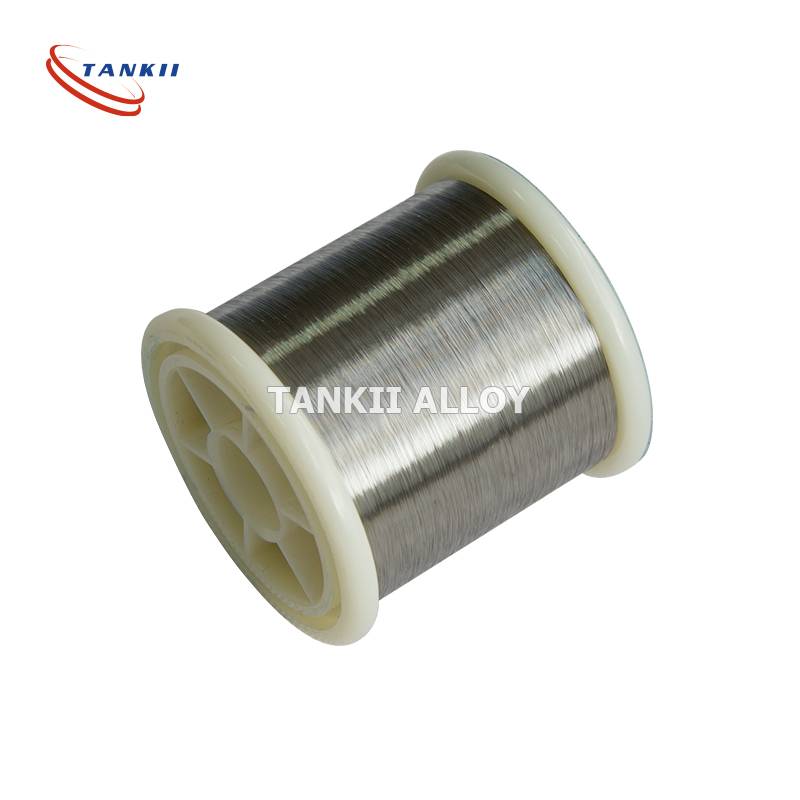

1Cr13Al4 FeCrAl alloy Anti Oxidation Stranded Wire rau Ceramic Pad Heater

Kev piav qhia txog khoom

FeCrAl alloys cua sov ribbon hlau

1. Kev Taw Qhia Txog Cov Khoom

FeCrAl alloy yog ferritic hlau-chromium-aluminium alloy nrog siab resistivity thiab muaj superior oxidation tsis kam rau kev siv ntawm qhov kub txog li 1450 centigrade degree., piv rau lwm cov lag luam Fe thiab Ni puag alloy.

2. Daim Ntawv Thov

Peb cov khoom siv dav dav rau kev lag luam tshuaj lom neeg, metallurgy mechanism, iav kev lag luam, ceramic kev lag luam, khoom siv hauv tsev thiab lwm yam.

3. Cov Khoom

Qib:1Cr13Al4

Cov Tshuaj Muaj pes tsawg leeg: Cr 12-15% Al 4.0-4.56.0% Fe Tshuav Nyiaj

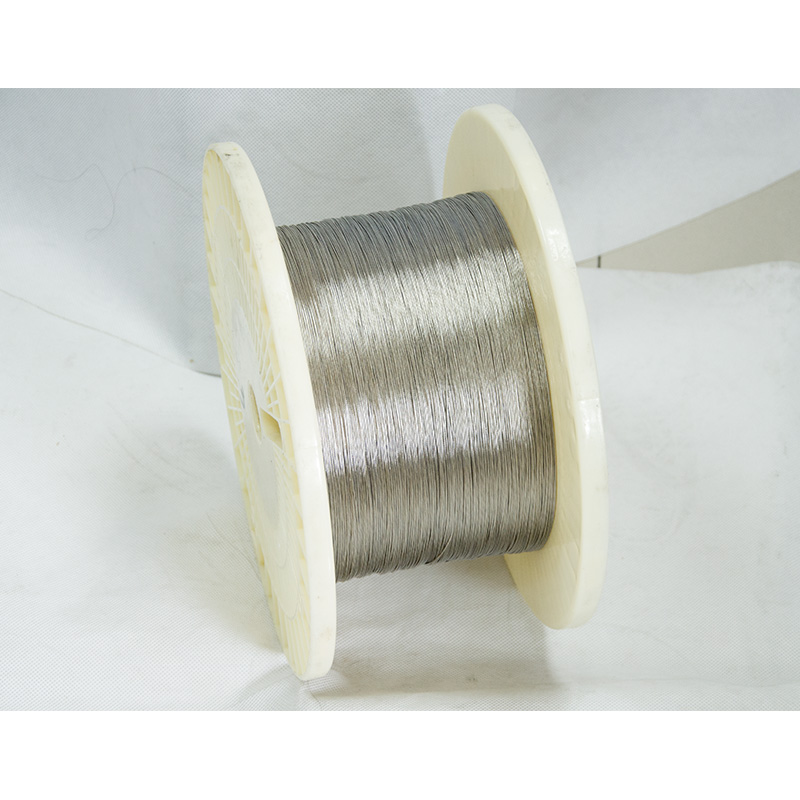

Cov xov hlau uas muaj hlua khi yog ua los ntawm ntau cov xov hlau me me uas muab khi ua ke los yog qhwv ua ke los ua ib lub xov hlau loj dua. Cov xov hlau uas muaj hlua khi yooj ywm dua li cov xov hlau khov uas muaj tib thaj chaw seem. Cov xov hlau uas muaj hlua khi yog siv thaum xav tau kev tiv taus hlau ntau dua. Cov xwm txheej zoo li no suav nrog kev sib txuas ntawm cov laug cam hauv cov khoom siv ntau lub rooj tsavxwm luam tawm, qhov twg qhov khov kho ntawm cov xov hlau khov kho yuav tsim kev ntxhov siab ntau dhau vim yog kev txav mus los thaum sib dhos lossis kev pabcuam; Cov xov hlau AC rau cov khoom siv hluav taws xob; cov xov hlau suab paj nruag; cov xov hlau nas khoos phis tawj; cov xov hlau vuam electrode; cov xov hlau tswj uas txuas cov khoom siv tshuab txav mus los; cov xov hlau tshuab mining; cov xov hlau tshuab tom qab; thiab ntau lwm yam.

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj