Txais tos rau peb cov vev xaib!

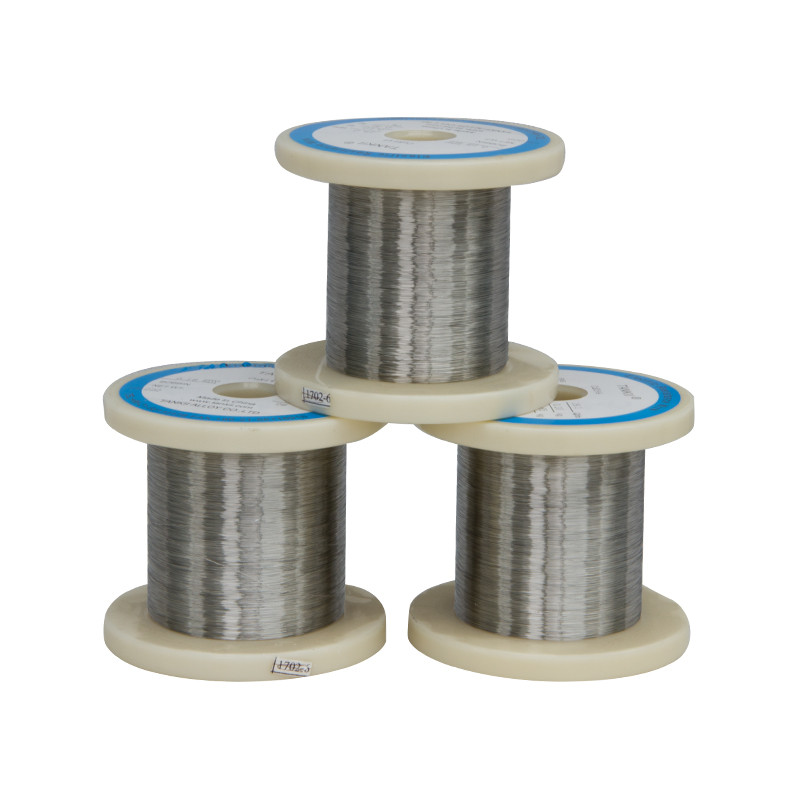

1j77 Mos Sib Nqus Alloy Hlau Ni77Mo4Cu5

Cov khoom sib xyaw ib txwm muaj%

| Ni | 75.5~78 | Fe | Bal. | Mn | 0.3~0.6 | Si | 0.15~0.3 |

| Mo | 3.9~4.5 | Cu | 4.8~6.0 | ||||

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

Cov khoom siv kho tshuab ib txwm muaj

| Lub zog tawm los | Lub zog tensile | Kev ntev |

| Mpa | Mpa | % |

| 980 | 980 | 2~40 |

Cov khoom siv lub cev ib txwm muaj

| Qhov Ceev (g/cm3) | 8.6 |

| Hluav taws xob resistivity ntawm 20ºC (Om * mm2 / m) | 0.55 |

| Coefficient ntawm linear expansion (20ºC ~ 200ºC) X10-6 / ºC | 10.3~11.5 |

| Cov coefficient ntawm kev sib nqus ntawm qhov saturation λθ / 10-6 | 2.4 |

| Curie point Tc/ ºC | 350 |

| Cov khoom sib nqus ntawm cov hlau nplaum uas muaj permeability siab hauv cov teb tsis muaj zog | |||||||

| Ni77Mo4Cu5 | Kev nkag tau thawj zaug | Qhov siab tshaj plaws permeability | Kev yuam | Kev sib nqus induction zog ntawm saturation | |||

| Daim kab xev/daim ntawv qub. Thickness, hli | μ0.08/ (mH/m2) | μm/ (mH/m) | Hc/ (A/m) | BS/ T | |||

| ≥ | ≤ | ||||||

| 0.01 hli | 17.5 | 87.5 | 5.6 | 0.75 | |||

| 0.1 ~ 0.19 hli | 25.0 | 162.5 | 2.4 | ||||

| 0.2 ~ 0.34 hli | 28.0 | 225.0 | 1.6 | ||||

| 0.35 ~ 1.0 hli | 30.0 | 250.0 | 1.6 | ||||

| 1.1 ~ 2.5 hli | 27.5 | 225.0 | 1.6 | ||||

| 2.6 ~ 3.0 hli | 26.3 | 187.5 | 2.0 | ||||

| hlau txias kos | |||||||

| 0.1 hli | 6.3 | 50 | 6.4 | ||||

| Bar | |||||||

| 8-100 hli | 25 | 100 | 3.2 | ||||

| Hom kev kho cua sov Ni77Mo4Cu5 | |

| Cov xov xwm kub hnyiab | Nqus tsev nrog lub siab seem tsis siab tshaj 0.1Pa, hydrogen nrog lub dew point tsis siab tshaj -40 ºC. |

| Qhov kub thiab txias ntawm cua sov | 1100~1150ºC |

| Lub sijhawm tuav | 3~6 |

| Tus nqi txias | Nrog 100 ~ 200 ºC / h txias rau 600 ºC, txias sai rau 300ºC |

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj