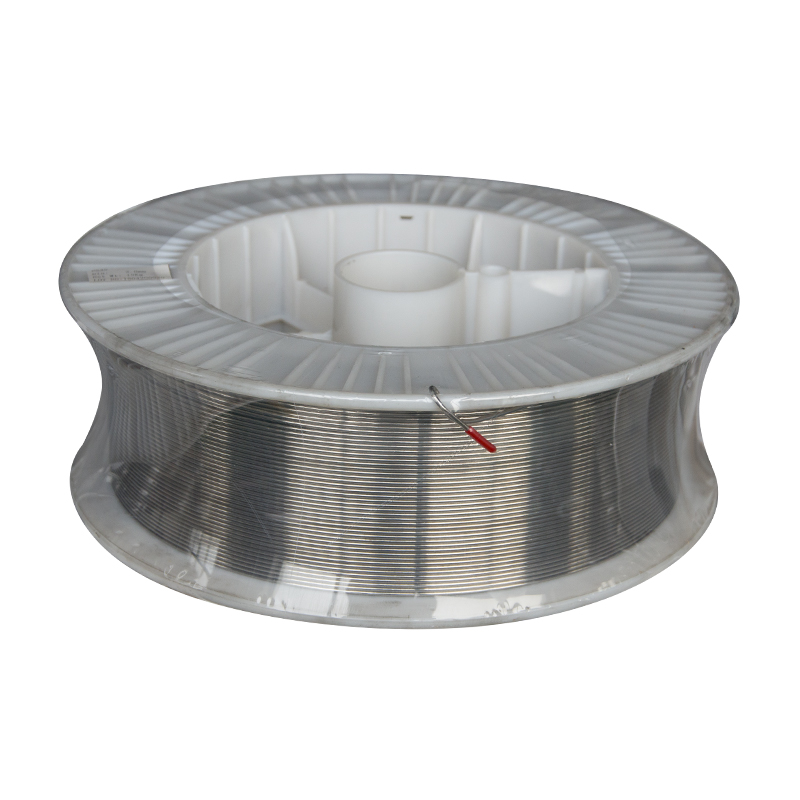

4j36 Invar Alloy Hlau Qis Expansion Alloy Feni36 Hlau

4J36 (Invar) siv rau qhov twg xav tau kev ruaj khov siab, xws li cov cuab yeej siv precision, moos, seismic creep gauges, TV shadow-mask frames, valves hauv motors, thiab antimagnetic watches. Hauv kev soj ntsuam av, thaum yuav tsum ua qhov siab tshaj plaws (high-precision) leveling leveling, Level staff (leveling rod) siv yog ua los ntawm Invar, es tsis txhob siv ntoo, fiberglass, lossis lwm yam hlau. Invar struts tau siv rau hauv qee lub pistons los txwv lawv qhov thermal expansion hauv lawv lub tog raj kheej.

4J36 siv oxyacetylene vuam, hluav taws xob arc vuam, vuam thiab lwm yam kev vuam. Vim tias qhov coefficient ntawm kev nthuav dav thiab cov tshuaj lom neeg muaj feem cuam tshuam nrog cov hlau sib xyaw yuav tsum tsis txhob raug vuam vim tias kev vuam ua rau muaj kev hloov pauv hauv cov khoom sib xyaw, nws yog qhov zoo dua los siv argon arc vuam vuam cov hlau filler uas muaj 0.5% txog 1.5% titanium, kom txo qhov vuam porosity thiab tawg.

Cov khoom sib xyaw ib txwm muaj%

| Ni | 35~37.0 | Fe | Bal. | Co | - | Si | ≤0.3 |

| Mo | - | Cu | - | Cr | - | Mn | 0.2~0.6 |

| C | ≤0.05 | P | ≤0.02 | S | ≤0.02 |

Tus lej ntawm kev nthuav dav

| θ/ºC | α1/10-6ºC-1 | θ/ºC | α1/10-6ºC-1 |

| 20~-60 | 1.8 | 20 ~ 250 | 3.6 |

| 20~-40 | 1.8 | 20 ~ 300 | 5.2 |

| 20~-20 | 1.6 | 20 ~ 350 | 6.5 |

| 20~-0 | 1.6 | 20 ~ 400 | 7.8 |

| 20 ~ 50 | 1.1 | 20 ~ 450 | 8.9 |

| 20 ~ 100 | 1.4 | 20 ~ 500 | 9.7 |

| 20 ~ 150 | 1.9 | 20 ~ 550 | 10.4 |

| 20 ~ 200 | 2.5 | 20 ~ 600 | 11.0 |

Cov khoom siv lub cev ib txwm muaj

| Qhov Ceev (g/cm3) | 8.1 |

| Kev tiv taus hluav taws xob ntawm 20ºC (OMmm2 / m) | 0.78 |

| Qhov ntsuas kub ntawm kev tiv thaiv (20ºC ~ 200ºC) X 10-6 / ºC | 3.7~3.9 |

| Kev ua kom sov, λ / W / (m * ºC) | 11 |

| Curie point Tc/ ºC | 230 |

| Modulus Elastic, E/ Gpa | 144 |

| Cov txheej txheem kho cua sov | |

| Kev ua kom sov rau kev txo kev ntxhov siab | Kub txog 530 ~ 550ºC thiab tuav 1 ~ 2 teev. Txias cia |

| kev ua kom sov | Yuav kom tshem tawm cov tawv tawv, uas yuav tsum tau coj tawm hauv cov txheej txheem txias-dov, txias kos duab. Annealing xav tau cua sov rau 830 ~ 880ºC hauv lub tshuab nqus tsev, tuav 30 feeb. |

| Cov txheej txheem kev ruaj khov |

|

| Cov kev ceev faj |

|

Cov khoom siv kho tshuab ib txwm muaj

| Lub zog tensile | Kev ntev |

| Mpa | % |

| 641 | 14 |

| 689 | 9 |

| 731 | 8 |

Qhov kub thiab txias ntawm kev tiv taus

| Qhov kub thiab txias, ºC | 20 ~ 50 | 20 ~ 100 | 20 ~ 200 | 20 ~ 300 | 20 ~ 400 |

| aR/ 103 *ºC | 1.8 | 1.7 | 1.4 | 1.2 | 1.0 |

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj