4J52 / Pernifer 50 Iav Sealing 52 Alloy Tube

Qhov loj loj:

* Ntawv-Thib 0.1mm ~ 40.0 hli, Dav, Dav :00mm, Rolled: Cold Rolled (kub), ci, ci annealed

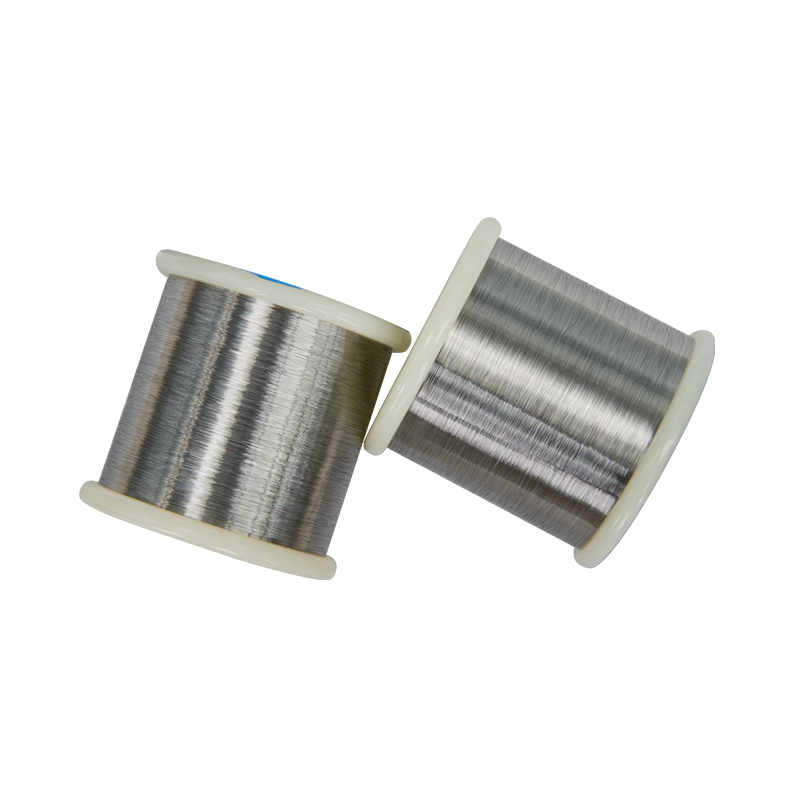

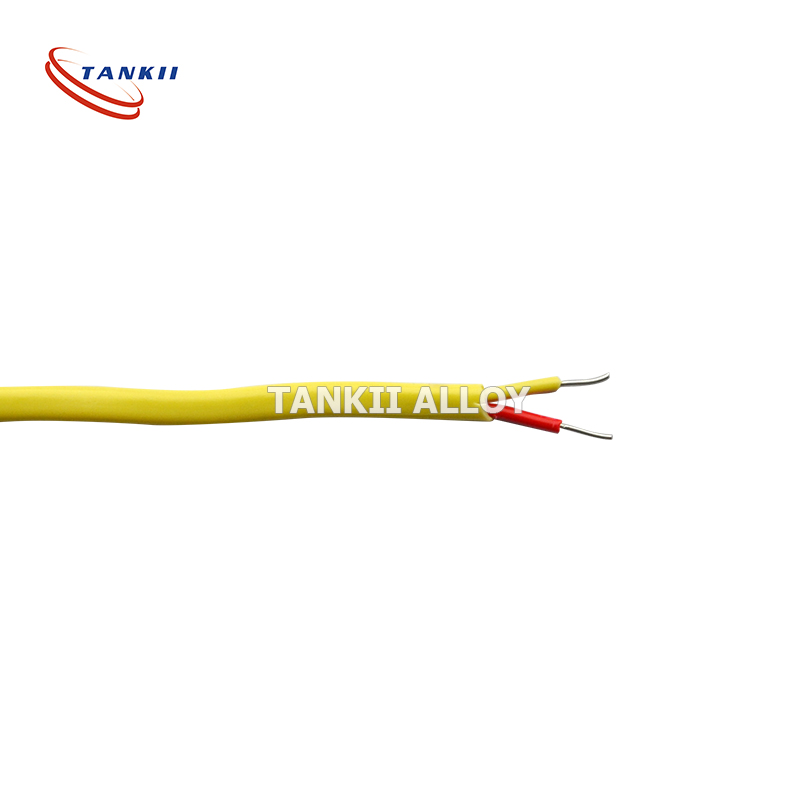

* Puag ncig xaim xaim-Dia 0.1mm ~ dia 5.0mm, mob: Khaub thuas drawn, ci, ci annealed

* Tiaj tus hlau-Dia 0.5mm ~ dia 5.0mm, ntev, ntev: ≤1000mm, mob: Tiaj tus dov, ci annealed

* Bar-Dia 5.0mm ~ ua dia 8.0 hli, ntev: ≤2000mm, mob: Khaub thuas kos, ci, ci annealed

Dia 8.0 hli ~ lawj, ntev, ntev: ≤2500mm, mob dov, ci, ci annealed

Dais 32.0 hli ~ Dia 180.0 hli, Ntev, ntev: DEPTED: Peeled, muab, kub kho

* Capillary-Od 8.0mm ~ 1.0 hli, id 0.1mm ~ 8.0 hli, ntev: ≤2500mm, mob kos, ci, ci annealed.

* Yeeb nkab-Yog 8.0mm ~ 8.0mm, ID 8.0mm ~ 129 hli ~ 129mm, ntev: ≤4,Kr: ≤: CURTORM, TXIAS TXIAS, ci, ci annealed.

Chemistry:

| Cr | Al | C | Fe | Mn | Si | P | S | Ni | Mg | |

| Lub min | - | - | - | - | - | - | - | - | 50.5 | - |

| Tus zuag | 0.25 | 0.10 | 0.05 | Bal. | 0.60 | 0.30 | 0.025 | 0.025 | - | 0.5 |

Qhov ntsuas nruab nrab nthuav dav coefficient:

| Teem nqi | α1 / 10-6ºC-1 | |||||||

| 20 ~ 100ºC | 20 ~ 200ºC | 20 ~ 300ºC | 20 ~ 350ºC | 20 ~ 400ºC | 20 ~ 450ºC | 20 ~ 500ºC | 20 ~ 600ºC | |

| 4J52 | 10.3 | 10.4 | 10.2 | 10.3 | 10.3 | 10.3 | 10.3 | 10.8 |

Khoom:

| Yam tseem ceeb | Kwv yees li. Lub zog tensile | Kwv yees li. Kev khiav hauj lwm kub | ||

| N / mm² | ksi | ° C | ° F | |

| Ib qho tseem ceeb | 450 - 550 | 65 - 80 | Txog li +450 | Txog li +840 |

| Nyuaj kos | 700 - 900 | 102 - 131 | Txog li +450 | Txog li +840 |

| Txoj kev sib sau: |

| Lub alloy muaj kev du me me thiab tuaj yeem tsim los ntawm tus qauv txhais tau tias. |

| Vuam: |

| Vuam los ntawm cov txheej txheem pa hluav taws xob yog qhov tsim nyog rau cov alloy. |

| Kev Kho Cua Sov: |

| Alloy 52 yuav tsum tau qhia tawm ntawm 1500f ua raws li los ntawm huab cua txias. Qib Nruab Nrab Kev Sib Raug Zoo Yuav Ua Tau Thaum 1000f. |

| Forging: |

| Forging yuav tsum tau ua nyob rau ntawm ib tug kub ntawm 2150 F. |

| Cov Haujlwm Txias: |

| Lub alloy yog yooj yim txias ua haujlwm. Kev kos duab kom sib sib zog yuav tsum tau sau tseg rau qhov kev ua haujlwm thiab qib kawm rau kev tsim dav dav. |