5J1480 135 Lub ntsuas sov Bimetallic strip qis coefficient ntawm kev nthuav dav

| Daim Ntawv Thov: | Phaj Boiler | Dav: | 5 hli ~ 120 hli |

|---|---|---|---|

| Tus Qauv: | GB, ASTM, JIS, AISI, BS | Khoom siv: | Bimetallic |

| Qhov tuab: | 0.1 hli | Lub Npe Khoom: | Cov Hlau Bimetallic |

| Xim: | Nyiaj | Lo lus tseem ceeb: | Bimetallic Strip |

| Qhov Tseem Ceeb: | coefficient qis ntawm kev nthuav davBimetallic strips, 135 Bimetallic strip, 5J1480Bimetallic strips | ||

Huona Alloy-5J1480(Bimetallic strip)

(Lub Npe Feem Ntau: 135)

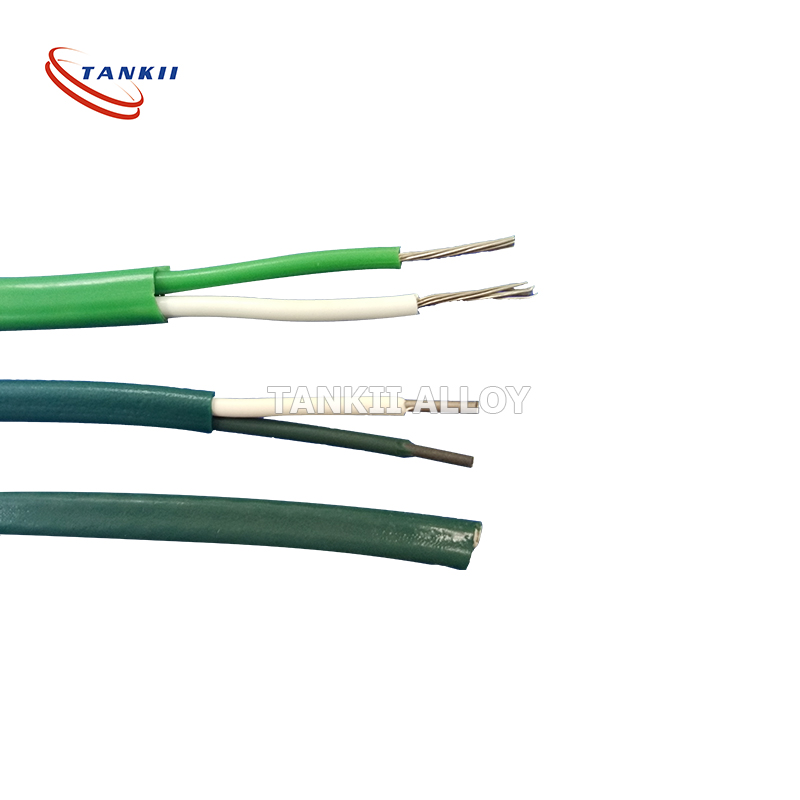

Daim hlau bimetallic yog siv los hloov qhov kub thiab txias mus ua qhov hloov pauv mechanical. Daim hlau no muaj ob daim hlau sib txawv uas nthuav dav ntawm qhov sib txawv thaum lawv raug cua sov, feem ntau yog hlau thiab tooj liab, lossis qee zaum hlau thiab tooj dag. Cov hlau no raug sib txuas ua ke thoob plaws lawv qhov ntev los ntawm kev riveting, brazing lossis welding. Qhov sib txawv ntawm kev nthuav dav yuam kom daim hlau tiaj tiaj khoov ib txoj kev yog tias raug cua sov, thiab nyob rau hauv qhov kev coj rov qab yog tias txias qis dua nws qhov kub pib. Cov hlau uas muaj cov coefficient siab dua ntawm thermal expansion yog nyob rau sab nraud ntawm qhov nkhaus thaum daim hlau raug cua sov thiab nyob rau sab hauv thaum txias.

Qhov kev hloov pauv ntawm sab ntawm daim kab xev yog loj dua li qhov kev nthuav dav me me hauv ob qho hlau. Cov nyhuv no yog siv rau hauv ntau yam khoom siv kho tshuab thiab hluav taws xob. Hauv qee daim ntawv thov, daim kab xev bimetal yog siv rau hauv daim ntawv tiaj tus. Hauv lwm tus, nws yog qhwv rau hauv lub kauj rau kev sib dhos. Qhov ntev dua ntawm cov qauv coiled muab kev nkag siab zoo dua.

Daim duab ntawm ibbimetallic stripsqhia txog qhov sib txawv ntawm kev nthuav dav thermal hauv ob lub hlau ua rau muaj kev hloov pauv loj dua ntawm daim kab xev.

Kev sau ua ke

| Qib | 5J1480 |

| Txheej nthuav dav siab | Ni22Cr3 |

| Txheej txheem nthuav dav tsawg | Ni36 |

Cov tshuaj lom neeg muaj pes tsawg leeg (%)

| Qib | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Ni36 | ≤0.05 | ≤0.3 | ≤0.6 | ≤0.02 | ≤0.02 | 35~37 | - | - | Bal. |

| Qib | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Ni22Cr3 | ≤0.35 | 0.15~0.3 | 0.3~0.6 | ≤0.02 | ≤0.02 | 21~23 | 2.0~4.0 | - | Bal. |

Cov khoom siv lub cev ib txwm muaj

| Qhov Ceev (g/cm3) | 8.2 |

| Hluav taws xob resistivity ntawm 20 ℃ (Ωmm)2/m) | 0.8 ± 5% |

| Kev ua kom sov, λ / W / (m * ℃) | 22 |

| Modulus Elastic, E/ Gpa | 147~177 |

| Khoov K / 10-6℃-1(20 ~ 135 ℃) | 14.3 |

| Kub thiab txias dabtsi yog khoov F/(20~130℃)10-6℃-1 | 26.2% ± 5% |

| Qhov kub uas tso cai (℃) | -70~ 350 |

| Kub kab ncaj (℃) | -20~ 180 |

Daim Ntawv Thov: Cov khoom siv feem ntau yog siv rau hauv cov khoom siv tswj tsis siv neeg thiab cov cuab yeej siv (piv txwv li: cov ntsuas kub tso pa tawm, cov thermostats, cov tswj hluav taws xob, qhov kub thiab txias relay, kev tiv thaiv tsis siv neeg, diaphragm meters, thiab lwm yam) ua kev tswj kub, kev them nyiaj kub, kev txwv tam sim no, qhov ntsuas kub thiab lwm yam khoom kub-rhiab.

Feature: Cov yam ntxwv yooj yim ntawm Thermostat Bimetallic yog khoov deformation nrog kev hloov pauv kub, ua rau muaj lub sijhawm.

Qhov ntsuas kub Bimetallic Strip expansion coefficient txawv ntawm ob lossis ntau txheej ntawm hlau lossis alloy raws tag nrho qhov chaw sib cuag ruaj khov, muaj qhov hloov pauv ntawm qhov kub thiab txias tshwm sim thermosensitivefunctional composites. Qhov twg qhov siab dua expansion coefficient ntawm cov txheej nquag yog ib txheej hu ua qhov qis coefficient ntawm kev nthuav dav ntawm txheej hu ua passive txheej.

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj