Txais tos rau peb cov vev xaib!

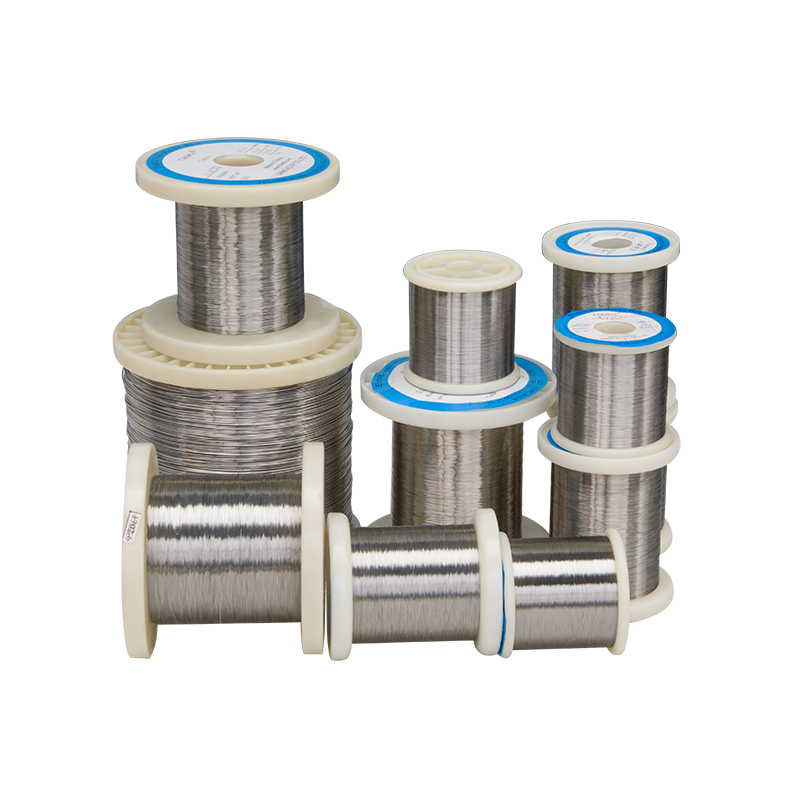

AG-Cu Nyiaj Tooj Liab Hlau

tab sis cov ntaub ntawv tseem ceeb ntawm kev sib txuas yog AgCu7.5, AgCu25, AgCu28,AgCu55, thiab lwm yam, thiab AgCu28 siv dav. Lawv muaj kev coj ua zoo, kev npliag thiab kev ntub dej, thiab siv dav hauv kev lag luam hluav taws xob. Vim tias qhov tsis kam rau lub sijhawm ntev hauv qab qhov kub siab, nws tsuas yog haum rau brazing qhov chaw uas qhov kub ua haujlwm qis dua 400ºC.

Siv ua cov nyiaj npib thiab kho kom zoo nkauj. Cov hlau sib xyaw ua cov nyiaj npib yog AgCu7.5, AgCu8,AgCu10, thiab lwm yam; cov hlau siv los ua kho kom zoo nkauj yog AgCu8.4, AgCu12.5, thiab lwm yam

Cov khoom sib xyaw ib txwm muaj%

| Ag | Cu | Sn | Ni | Pb | Fe | Sb | Bi | |

| AgCu4 | 96+/-0.3 | 4+0.3/-0.5 | ≤0.005 | ≤0.05 | ≤0.002 | ≤0.002 | ||

| AgCu5 | 95+/-0.3 | 5+0.3/-0.5 | ≤0.005 | ≤0.05 | ≤0.002 | ≤0.002 | ||

| AgCu7.5 | 92.5+/-0.3 | 7.5+0.3/-0.5 | ≤0.005 | ≤0.1 | ≤0.002 | ≤0.002 | ||

| AgCu8.4 | 91.6+/-0.3 | 8.4+/-0.5 | ≤0.005 | ≤0.1 | ≤0.002 | ≤0.002 | ||

| AgCu10 | 90 +/- 0.3 | 10+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu12.5 | 87.5+/-0.3 | 12.5+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu20 | 80 +/- 0.3 | 20+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu23 | 77+/-0.5 | 23+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu25 | 75+/-0.5 | 25+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu26 | 74+/-0.5 | 26+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu28 | 72+/-0.5 | 28+/-0.5 | ≤0.005 | ≤0.2 | ≤0.002 | ≤0.002 | ||

| AgCu50 | 50+/-0.5 | 50+/-0.5 | ≤0.005 | ≤0.25 | ≤0.002 | ≤0.002 | ||

| AgCu99 | 1+/-0.2 | 99 + 0.2 / -0.5 | ||||||

| AgCu18Ni2 | 80+/-0.5 | 18+/-0.5 | / | 2+/-0.3 |

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj