Txais tos rau peb cov vev xaib!

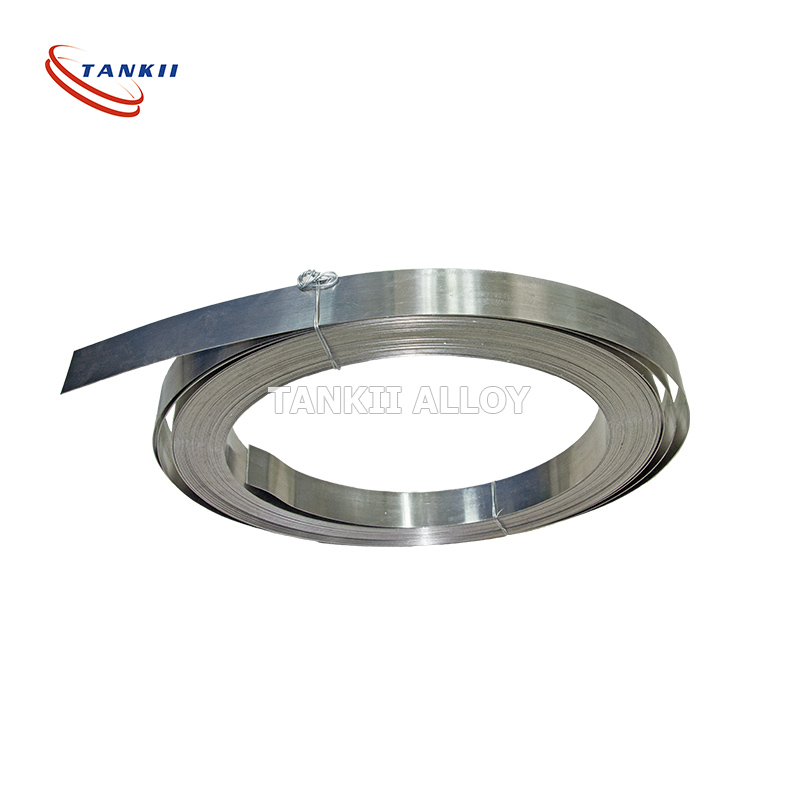

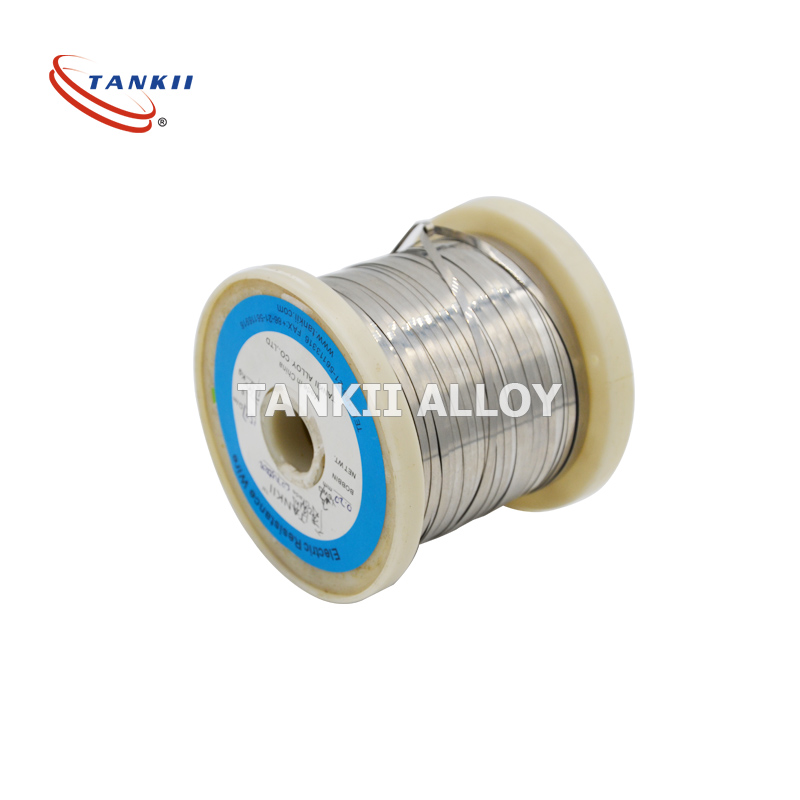

Constantan Tiaj Tus Hlau Tooj Liab Nickel Alloy 6j40 Ribbon 0.4 * 2mm

Tshiab Constantan Tiaj Tus Hlau Tooj Liab Nickel Alloy 6j11 Ribbon 0.4 * 2mm

| Yam ntxwv | Kev tiv taus (200C μ Ω . m) | Kub ua haujlwm siab tshaj plaws (0C) | Lub zog tensile (Mpa) | Qhov kub yaj (0C) | Qhov Ceev (g/cm3) | TCR x10-6/ 0C (20~600 0C) | EMF vs Cu (μ V / 0C) (0 ~ 100 0C) |

| Cov Npe ntawm Cov Hlau Alloy | |||||||

| NC003 (CuNi1) | 0.1 | 200 | ≥ 250 | 1095 | 8.9 | < 100 | -12 |

![]()

![]()

![]()

![]()

| Cov Khoom Siv Lub Cev | Kev ntsuas | Cov lus tawm tswv yim |

| Qhov Ceev | 8.94 g/cc | |

| Cov Khoom Siv Kho Tshuab | Kev ntsuas | Cov lus tawm tswv yim |

| Lub Zog Tensile, Qhov Kawg | 262 – 531 MPa | |

| Lub Zog Tensile, Cov Khoom Tawm | 276 – 524 MPa | Nyob ntawm kev siab nyiam |

| Kev ntev thaum tawg | 46.0% | ua 50.8mm. |

| Modulus ntawm Elasticity | 115 GPa | |

| Qhov sib piv ntawm Poissons | 0.310 | Xam tau |

| Kev siv tshuab tau | 20% | UNS C36000 (tooj dag txiav dawb) = 100% |

| Modulus txiav | 44.0 GPa | |

| Cov Khoom Siv Hluav Taws Xob | Kev ntsuas | Cov lus tawm tswv yim |

| Kev Tiv Thaiv Hluav Taws Xob | 0.0000120 ohm-cm @Kub 20.0 ° C | |

| Cov Khoom Siv Thermal | Kev ntsuas | Cov lus tawm tswv yim |

| CTE, linear | 17.5 µm/m-° C @Kub 20.0 - 300 ° C | |

| Peev Xwm Kub Tshwj Xeeb | 0.380 J/g-° C | |

| Kev Ua Kub | 64.0 W/mK @Kub 20.0 ° C | |

| Qhov Kub Yaj | < = 1125 ° C | Liquidus |

| Liquidus | 1125 ° C | |

| Cov Khoom Ua Haujlwm | Kev ntsuas | Cov lus tawm tswv yim |

| Kub Kub | 565 – 815 ° C | |

| Kub Ua Haujlwm Kub | 815 – 950 ° C | |

| Cov Khoom ntawm Cov Cheebtsam | Kev ntsuas | Cov lus tawm tswv yim |

| Tooj liab, Cu | > = 91.2% | |

| Hlau, Fe | 1.30 – 1.70% | |

| Ua los ntawm txhuas, Pb | < = 0.050% | |

| Manganese, Mn | 0.30 – 0.80% | |

| Nickel, Ni | 4.80 – 6.20% | |

| Zinc, Zn | < = 1.0% |

![]()

![]()

![]()

![]()

CuNi44 Cov Tshuaj Lom Zem,%

| Ni | Mn | Fe | Si | Cu | Lwm yam | Cov Lus Qhia ROHS | |||

| Cd | Pb | Hg | Cr | ||||||

| 44 | 1% | 0.5 | - | Bal | - | ND | ND | ND | ND |

![]()

![]()

![]()

![]()

Cov Khoom Siv Kho Tshuab

| Max Kev Pabcuam Txuas Ntxiv Mus | 400ºC |

| Kev tiv taus ntawm 20ºC | 0.49 ± 5% ohm mm2 / m |

| Qhov Ceev | 8.9 g/cm3 |

| Kev Ua Kub | -6 (Tshaj plaws) |

| Qhov Kub Yaj | 1280ºC |

| Lub zog tensile, N / mm2 Annealed, Mos | 340 ~ 535 Mpa |

| Lub zog tensile, N / mm3 Txias dov | 680 ~ 1070 Mpa |

| Kev ncua ntev (anneal) | 25% (Yam tsawg kawg nkaus) |

| Kev ncab (kub dov) | ≥Min)2% (Min) |

| EMF vs Cu, μV/ºC (0~100ºC) | -43 |

| Cov Qauv Micrographic | austenite |

| Khoom Siv Sib Nqus | Tsis yog |

![]()

![]()

![]()

![]()

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj