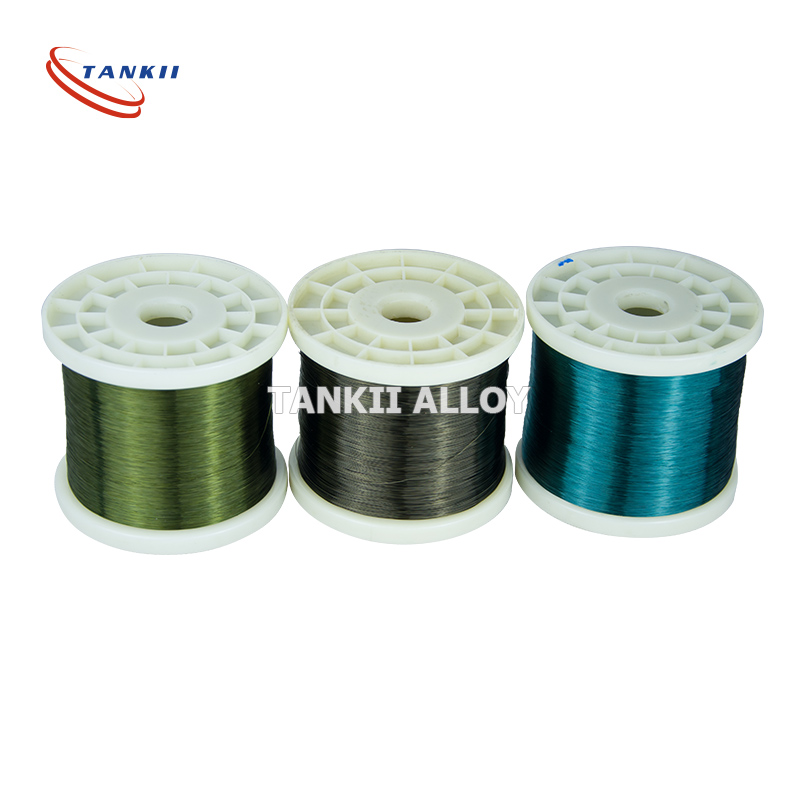

tooj liab hlau thermal chav kawm C / 200 * C ANSI hom MW35C lossis IEC 317-13. Polyester-imide thiab polyamide-imide ob txheej enameled Winding hlau

hlau tooj liab chav kawm thermal C/ 200 * C ANSI HOM MW35C lossis IEC 317-13. Polyester-imide thiabpolyamide-imideob txheej enameled Winding hlau

Kev piav qhia txog khoom

Cov xov hlau tiv thaiv enameled no tau siv dav rau cov qauv resistors, tsheb

qhov chaw, winding resistors, thiab lwm yam siv covkev rwb thaiv tsevkev ua tiav zoo tshaj plaws rau cov ntawv thov no, siv tag nrho cov yam ntxwv tshwj xeeb ntawm cov txheej enamel.

Tsis tas li ntawd, peb yuav ua cov txheej txheem enamelkev rwb thaiv tsevntawm cov hlau muaj nqis xws li hlau nyiaj thiab hlau platinum raws li kev txiav txim. Thov siv qhov kev tsim khoom no-raws li kev txiav txim.

Hom Nichrome Hlau

NiCr80/20, NiCr70/30, NiCr60/15, NiCr90/10, NiCr35/20, NiCr30/20

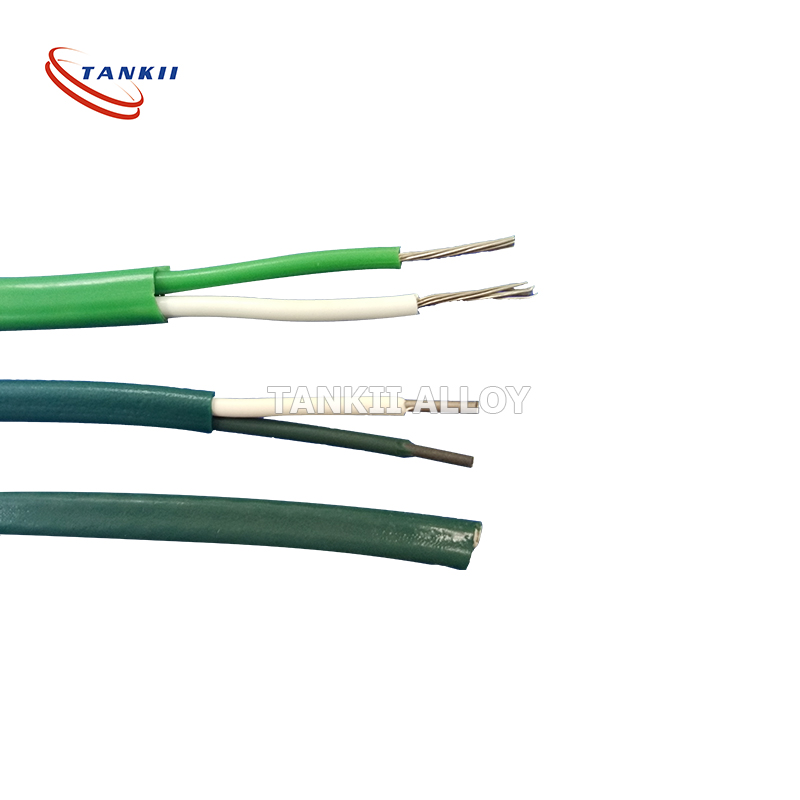

Hom Kev Rwb Thaiv Tsev

| Lub Npe Rwb Thaiv Tsev-enamelled | Thermal QibºC (lub sijhawm ua haujlwm 2000h) | Lub Npe Tus lej | GB Code | ANSI. HOM |

| Polyurethane enamelled hlau | 130 | UEW | QA | MW75C |

| Polyester enamelled hlau | 155 | PEW | QZ | MW5C |

| Polyester-imide enamelled hlau | 180 | EIW | QZY | MW30C |

| Polyester-imide thiab polyamide-imide ob txheej enameled hlau | 200 | EIWH (DFWF) | QZY/XY | MW35C |

| Polyamide-imide enamelled hlau | 220 | AIW | QXY | MW81C |

Hom Hlau Hlau Liab Qab

Cov hlau uas peb ua tau enamelled yog tooj liab-nickel hlau hlau, Constantan hlau, Manganin hlau. Kama hlau, NiCr hlau hlau, FeCrAl hlau hlau thiab lwm yam hlau hlau hlau

| lub ntsiab khoom vaj khoom tsev hom | Cuni1 | CuNI2 | CuNI6 | CuNi8 | CuNI10 | CuNi14 | CuNi19 | CuNi23 | CuNi30 | CuNi34 | CuNI44 | ||

| lub ntsiab tshuaj lom neeg kev sau ua ke | Ni | 1 | 2 | 6 | 8 | 10 | 14.2 | 19 | 23 | 30 | 34 | 44 | |

| MN | / | / | / | / | / | 0.3 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | ||

| CU | so | so | so | so | so | so | so | so | so | so | so | ||

| siab tshaj plaws ua haujlwm kub | / | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 | 350 | 400 | ||

| qhov ceev g/cm3 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | ||

| kev tiv taus ntawm 20 ° c | 0.03 ± 10% | 0.05± 10% | 0.10 ± 10% | 0.12± 10% | 0.15± 10% | 0.20 ± 5% | 0.25 ± 5% | 0.30 ± 5% | 0.35± 5% | 0.40 ± 5% | 0.49± 5% | ||

| kub tus lej ntawm kev tiv thaiv | <100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 | -0 | <-6 | ||

| tensile lub zog mpa | >210 | >220 | >250 | >270 | >290 | >310 | >340 | >350 | >400 | >400 | >420 | ||

| kev ntev | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | ||

| yaj taw tes °c | 1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 | 1180 | 1280 | ||

| tus lej ntawm kev coj hluav taws xob | 145 | 130 | 92 | 75 | 59 | 48 | 38 | 33 | 27 | 25 | 23 |

nicr8020 hlau cua sov hlau

1. Txog Nichrome hlau

Nichrome alloy suav nrog cov nickel ntshiab, NiCr alloy, Fe-Cr-Al alloy thiab tooj liab nickel alloy.

Cov hlau nickel chrome: Ni80Cr20, Ni70Cr30, Ni60Cr15, Ni35Cr20, Ni30Cr20, Cr25Ni20, nickel ntshiab Ni200 thiab Ni201

2. Qhov Zoo Tshaj Plaws thiab Daim Ntawv Thov

1. Nickel-chromium, nickel-chromium alloy nrog siab thiab ruaj khov tsis kam, corrosion tsis kam, nto oxidation tsis kam yog qhov zoo, zoo dua nyob rau hauv kub siab thiab seismic zog, zoo ductility, zoo workability thiab weldability.

2. Peb cov khoom siv dav dav rau kev lag luam tshuaj lom neeg, metallurgy mechanism, iav kev lag luam, ceramic kev lag luam, khoom siv hauv tsev thiab lwm yam.

3. Cov tshuaj lom neeg muaj pes tsawg leeg:

| Hom | Cov tshuaj lom neeg muaj pes tsawg leeg | Si | Cr | Ni | Al | Fe | |||

| C | P | S | Mn | ||||||

| Tsis ntau tshaj | |||||||||

| Cr20Ni80 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 20.0-23.0 | nyob twj ywm | ≤0.50 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.020 | 0.015 | 0.60 | 0.75-1.60 | 15.0-18.0 | 55.0-61.0 | ≤0.50 | nyob twj ywm |

| Cr20Ni35 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-3.00 | 18.0-21.0 | 34.0-37.0 | - | nyob twj ywm |

| Cr20Ni30 | 0.08 | 0.020 | 0.015 | 1.00 | 1.00-2.00 | 18.0-21.0 | 30.0-34.0 | - | nyob twj ywm |

Thaum cov khoom nyob rau ntawm "M" xwm txheej, yuav tsum ua raws li tus qauv GB / T1234-1995

Kev tiv taus:

| Hom | Cr20Ni80 | Cr20Ni60 | Cr20Ni35 | Cr20Ni30 | ||

| Txoj kab uas hla hli | <0.50 | 0.50-3.0 | <0.50 | ≥0.50 | <0.50 | ≥0.50 |

| kev tiv taus (20 ° C) uΩ · m | 1.09 ± 0.05 | 1.13 ± 0.05 | 1.12 ± 0.05 | 1.15 ± 0.05 | 1.04 ± 0.05 | 1.06 ± 0.05 |

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj