Txais tos rau peb cov vev xaib!

CuNi10/C70700/W.Nr. 2.0811/Cu7061/CN15 /Cuprothal 15 hlau tsis kam siv thaum kub tsawg.

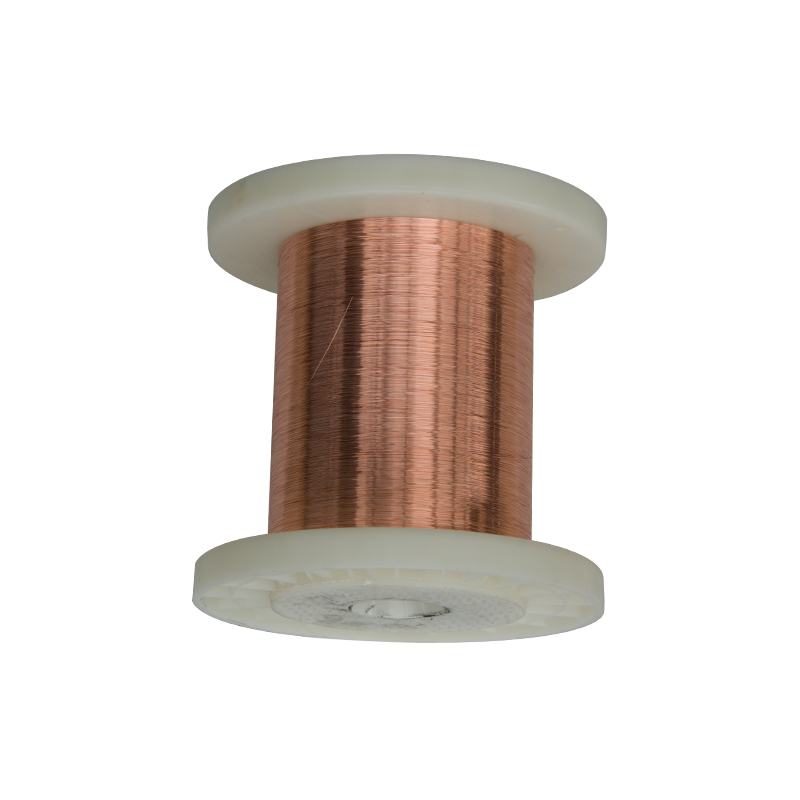

Vim muaj lub zog tensile siab thiab cov nqi resistivity nce ntxiv, CuNi10 yog thawj qhov kev xaiv rau kev siv ua cov xov hlau tsis kam. Nrog rau qhov sib txawv ntawm cov nickel hauv cov khoom no, cov yam ntxwv ntawm cov xov hlau tuaj yeem xaiv raws li koj xav tau. Cov xov hlau tooj liab-nickel alloy muaj nyob rau hauv cov xov hlau liab qab, lossis cov xov hlau enameled nrog txhua yam rwb thaiv tsev thiab tus kheej-bonding enamel.

Cov hlau no muaj qhov tshwj xeeb uas yooj yim hloov pauv, muaj kev tiv taus corrosion zoo txog thaum kub txog 400 ° C, thiab muaj peev xwm solder tau zoo. Cov chaw siv zoo tshaj plaws yog txhua hom kev tiv taus siv ntawmkub tsawg.

Cov Lus Qhia Txog Khoom

| JIS | JIS Code | Hluav taws xob Kev tiv taus [μΩm] | Qhov nruab nrab TCR [×10-6/℃] |

|---|---|---|---|

| GCN15 | C 2532 | 0.15 ± 0.015 | *490 |

(*) Tus nqi siv los ua piv txwv

| Thermal Kev nthuav dav Tus lej sib piv ×10-6/ | Qhov Ceev g/cm3 (20 ℃ | Qhov Kub Yaj ℃ | Qhov siab tshaj plaws Kev Ua Haujlwm Kub ℃ |

|---|---|---|---|

| 17.5 | 8.90 | 1100 | 250 |

| Tshuaj lom neeg Kev sau ua ke | Mn | Ni | Cu+Ni+Mn |

|---|---|---|---|

| (%) | ≦1.5 | 20 ~ 25 | ≧ 99 |

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj