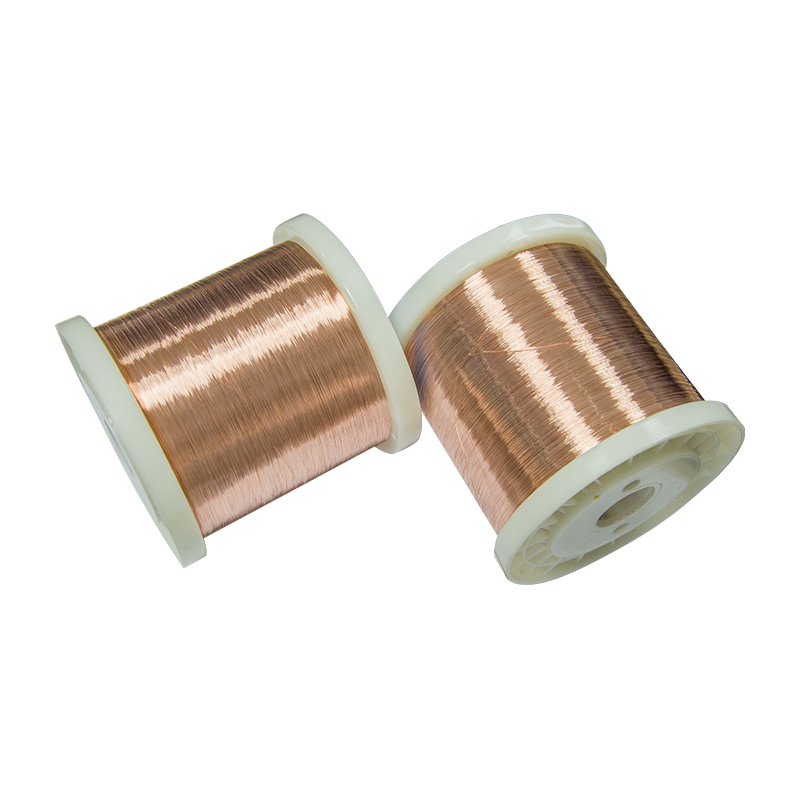

Dia 0.6mm Alloy M25 Tooj Liab Beryllium Hlau Rau Kev Sib Txuas Lus Choj

Kev piav qhia txog khoom

Cov Tshuaj Lom Zem (Qhov Hnyav Feem Pua) ntawmC17200 Beryllium Tooj Liab Alloy:

| Kev Muab Cov Kev Daws Teeb Meem | ||||||

| Cov hlau nplaum | Beryllium | Cobalt | Nickel | Co + Ni | Co+Ni+Fe | Tooj liab |

| C17200 | 1.80-2.00 | - | 0.20 Feeb | 0.20 Feeb | 0.60 Siab Tshaj | Qhov Nyiaj Tshuav |

Lus Cim: Tooj liab ntxiv rau qhov sib npaug 99.5% Min.

TCov Khoom Siv Lub Cev Ib Txwm Muaj ntawm C172:

Qhov Ceev (g/cm3): 8.36

Qhov ceev ua ntej hnub nyoog tawv (g/cm3): 8.25

Modulus Elastic (kg/mm2 (103)): 13.40

Cov Coefficient ntawm Kev Nthuav Dav Kub (20 °C txog 200 °C m/m/°C): 17 x 10-6

Kev Ua Kub (cal/(cm-s-°C)): 0.25

Qhov Kub Yaj (°C): 870-980

Peb muab cov khoom siv Common Temper:

| CuBeryllium Lub Npe | ASTM | Cov Khoom Siv Kho Tshuab thiab Hluav Taws Xob ntawm Tooj Liab Beryllium Strip | ||||||

| Lub Npe | Kev piav qhia | Lub zog tensile (Mpa) | Lub zog tawm los 0.2% offset | Feem pua ntawm kev ntev | KEV RUAJ NTSEG (HV) | KEV RUAJ NTSEG Rockwell B lossis C Scale | Kev Ua Hluav Taws Xob (% IACS) | |

| A | TB00 | Kev daws teeb meem Annealed | 410~530 | 190~380 | 35~60 | <130 | 45~78HRB | 15~19 |

| 1/2 H | TD02 | Ib Nrab Nyuaj | 580~690 | 510~660 | 12~30 | 180~220 | 88~96HRB | 15~19 |

| H | TD04 | Nyuaj | 680~830 | 620~800 | 2~18 | 220~240 | 96~102HRB | 15~19 |

| HM | TM04 | Zeb tawv | 930~1040 | 750~940 | 9~20 | 270~325 | 28 ~ 35HRC | 17~28 |

| SHM | TM05 | 1030~1110 | 860~970 | 9~18 | 295~350 | 31~37HRC | 17~28 | |

| XHM | TM06 | 1060~1210 | 930~1180 | 4~15 | 300~360 | 32 ~ 38HRC | 17~28 | |

Cov Txuj Ci Tseem Ceeb ntawm Beryllium Tooj Liab (Kev kho cua sov)

Kev kho cua sov yog cov txheej txheem tseem ceeb tshaj plaws rau lub kaw lus alloy no. Txawm hais tias txhua cov hlau tooj liab tuaj yeem ua kom tawv los ntawm kev ua haujlwm txias, tooj liab beryllium yog qhov tshwj xeeb hauv kev ua kom tawv los ntawm kev kho cua sov qis qis. Nws muaj ob kauj ruam yooj yim. Thawj qhov hu ua kev daws teeb meem annealing thiab qhov thib ob, nag lossis hnub nyoog hardening.

Kev Kho Mob Kub Hnyiab

Rau cov hlau CuBe1.9 (1.8-2%) feem ntau, cov hlau no raug cua sov ntawm 720 ° C thiab 860 ° C. Thaum lub sijhawm no, cov beryllium uas muaj nyob hauv cov hlau tooj liab yog "yaj" hauv cov hlau tooj liab (alpha theem). Los ntawm kev quenching sai sai rau chav tsev kub, cov qauv tshuaj khov kho no raug khaws cia. Cov khoom siv ntawm theem no yog mos heev thiab ductile thiab tuaj yeem ua haujlwm txias los ntawm kev kos duab, tsim dov, lossis txias taub hau. Kev ua haujlwm annealing tshuaj yog ib feem ntawm cov txheej txheem ntawm lub zeb thiab feem ntau tsis siv los ntawm cov neeg siv khoom. Kub, lub sijhawm ntawm qhov kub thiab txias, quench rate, qhov loj ntawm cov noob, thiab hardness yog cov yam ntxwv tseem ceeb heev thiab raug tswj hwm los ntawm TANKII.

Kev Ua Kom Ruaj Khov Thaum Muaj Hnub Nyoog

Kev laus tawv ua rau cov khoom siv muaj zog dua. Cov tshuaj tiv thaiv no feem ntau ua tiav ntawm qhov kub ntawm 260 ° C thiab 540 ° C nyob ntawm cov hlau thiab cov yam ntxwv xav tau. Lub voj voog no ua rau cov beryllium yaj kom precipitate ua ib theem beryllium nplua nuj (gamma) hauv lub matrix thiab ntawm cov ciam teb noob. Nws yog kev tsim cov precipitate no uas ua rau muaj kev nce ntxiv ntawm cov khoom siv zog. Qib ntawm cov khoom siv kho tshuab tau txais yog txiav txim siab los ntawm qhov kub thiab lub sijhawm ntawm qhov kub thiab txias. Nws yuav tsum tau lees paub tias beryllium tooj liab tsis muaj cov yam ntxwv laus hauv chav sov.

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj