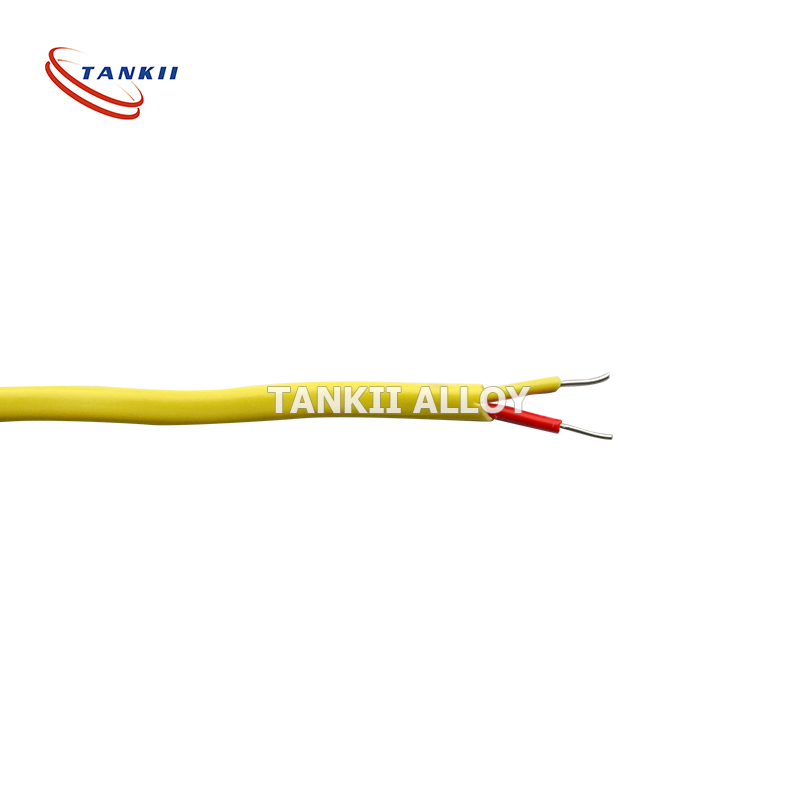

Cov Khoom Siv Rwb Thaiv Tsev PTFE Durable N Thermocouple Alloy

Cov Lus Qhia Tshwj Xeeb

1.Style: Hlau Txuas Ntxiv

2.Lub thermocouplehlau tooj liab

Kev faib tawm ntawm cov hlau tooj liab thermocouple

1. Thermocouple theem (qib kub siab). Hom hlau thermocouple no feem ntau yog tsim rau thermocouple hom K, J, E, T, N thiab L thiab lwm yam cuab yeej ntsuas kub siab, ntsuas kub, thiab lwm yam.

2. Kev them nyiaj rau qib hlau (qib kub qis). Hom hlau thermocouple no feem ntau yog tsim rau kev them nyiaj rau cable thiab txuas ntxiv ntawm ntau hom thermocouples ntawm hom S, R, B, K, E, J, T, N thiab L, cable cua sov, cable tswj thiab lwm yam.

Thermocouple ntau yam thiab cov ntsuas

| Thermocouple Variety thiab Index | ||

| Ntau yam | Hom | Kev Ntsuas Ntau Yam (°C) |

| NiCr-NiSi | K | -200-1300 |

| NiCr-CuNi | E | -200-900 |

| Fe-CuNi | J | -40-750 |

| Cu-CuNi | T | -200-350 |

| NiCrSi-NiSi | N | -200-1300 |

| NiCr-AuFe0.07 | NiCr-AuFe0.07 | -270-0 |

Qhov Loj thiab Kev kam rau siab ntawm Fiberglass Insulated Thermocouple Wire

Qhov Loj / Kev kam rau siab mm): 4.0 + -0.25

Xim code & pib calibration tolerances rau thermocouple hlau:

| Hom Thermocouple | ANSI Xim Code | Kev Ntsuas Qhov Kev Ntsuas Thaum Pib | ||||

| Cov Hlau Sib Xyaws | Kev kho kom raug | +/- Tus Neeg Coj | Lub tsho loj | Kub thiab txias | Tus Qauv Cov kev txwv | Tshwj xeeb Cov kev txwv |

| Hlau (+) vs. Constantan(-) | J | Dawb/Liab | Xim av | 0°C txog +285°C 285°C txog +750°C | ±2.2°C ± .75% | ±1.1°C ± .4% |

| CHROMEL(+) vs. ALUMEL(-) | K | Daj/Liab | Xim av | -200°C txog -110°C -110°C txog 0°C 0°C txog +285°C 285°C txog +1250°C | ± 2% ±2.2°C ±2.2°C ± .75% | ±1.1°C ± .4% |

| Tooj liab (+) vs. Constantan(-) | T | Xiav/Liab | Xim av | -200°C txog -65°C -65°C txog +130°C 130°C txog +350°C | ± 1.5% ±1°C ± .75% | ± .8% ± .5°C ± .4% |

| CHROMEL(+) vs. Constantan(-) | E | Xim av/Liab | Xim av | -200°C txog -170°C -170°C txog +250°C 250°C txog +340°C 340°C+900°C | ± 1% ±1.7°C ±1.7°C ± .5% | ±1°C ±1°C ± .4% ± .4% |

Xim Code & Kev Ntsuas Thawj Zaug rau Kev Txuas Hlau Ntev:

| Hom kev txuas ntxiv | ANSI Xim Code | Kev Ntsuas Qhov Kev Ntsuas Thaum Pib | ||||

| Cov Hlau Sib Xyaws | Kev kho kom raug | +/- Tus Neeg Coj | Lub tsho loj | Kub thiab txias | Tus Qauv Cov kev txwv | Tshwj xeeb Cov kev txwv |

| Hlau (+) vs. Constantan (-) | JX | Dawb/Liab | Dub | 0°C txog +200°C | ±2.2°C | ±1.1°C |

| CHROMEL (+) vs. ALUMEL (-) | KX | Daj/Liab | Xim daj | 0°C txog +200°C | ±2.2°C | ±1.1°C |

| Tooj liab (+) vs. Constantan (-) | TX | Xiav/Liab | Xiav | -60°C txog +100°C | ±1.1°C | ± .5°C |

| CHROMEL(+) vs. Constantan(-) | EX | Xim av/Liab | Xim av | 0°C txog +200°C | ±1.7°C | ±1.1°C |

PVC-PVC Lub Cev Khoom:

| Cov yam ntxwv | Kev rwb thaiv tsev | Lub tsho loj |

| Kev Tiv Thaiv Kev Sib Txhuam | Zoo | Zoo |

| Txiav Los Ntawm Kev Tiv Thaiv | Zoo | Zoo |

| Kev Tiv Thaiv Dej | Zoo heev | Zoo heev |

| Kev Tiv Thaiv Hlau Solder | Txom nyem | Txom nyem |

| Kub thiab txias rau kev pabcuam | 105ºC txuas ntxiv mus 150ºC ib leeg | 105ºC txuas ntxiv mus 150ºC ib leeg |

| Kev Ntsuas Hluav Taws | Tua tus kheej | Tua tus kheej |

Cov ntaub ntawv ntawm lub tuam txhab

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj