Txais tos rau peb cov vev xaib!

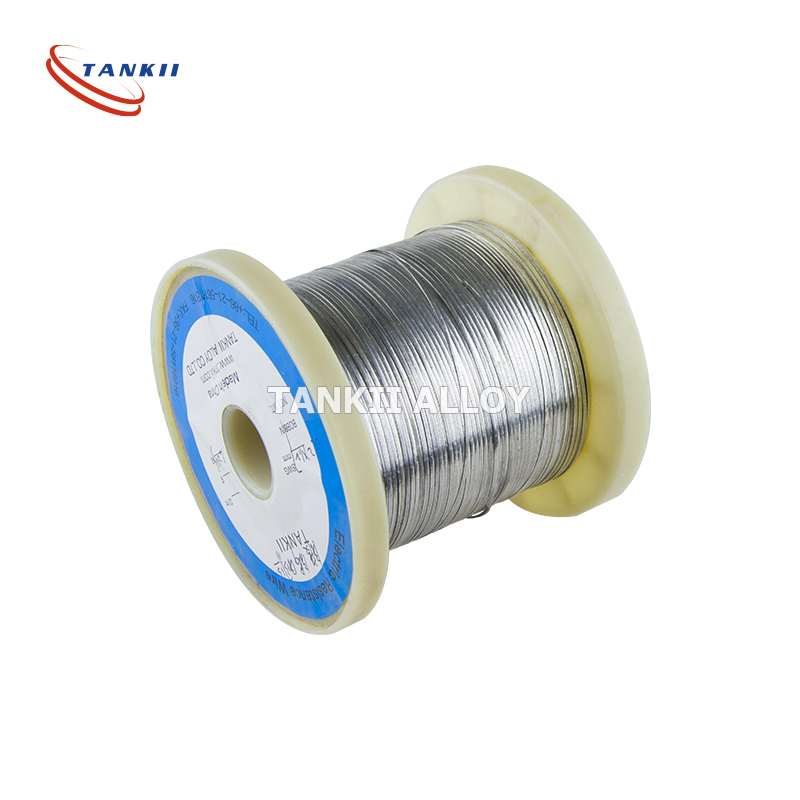

FeCr23Al5 / Cr23Al5 Kub Kub Hlau / Hlau Tiaj

FeCrAl 23-5/Hluav Taws Kub Kub/Hluav Taws Tiaj

Feem ntau siv rau hauv lub tshuab cua sov, cua sov thiab resistor, thiab lwm yam.

NiCr 80/20, NiCr 70/30, NiCr 60/15, NiCr 35/20

FeCrAl15-5, FeCrAl20-5, FeCrAl 25-5, thiab lwm yam ...

Constantan, Alloy 30, Alloy 60, Alloy 90, thiab lwm yam.

Kev Tiv Thaiv Hluav Taws Xob los ntawm 0.02 u ohm / m-1.53 u ohm / m

Ua haujlwm kub ntawm 200 C txog 1400 C

Thov hu rau peb yog tias muaj lus nug.

NiCr:

RESISTOHM 20, RESISTOHM 30, RESISTOHM 40, RESISTOHM 60, RESISTOHM 70, RESISTOHM 80

FeCrAl:

RESISTOHM 125, RESISTOHM 135, RESISTOHM 140,

RESISTOHM 145, RESISTOHM 153

CuNi

Constantan, Cuprothal 5, Cuprothal 10, Cuprothal 15, Cuprothal 30, Eurica

| FeCrAl Alloy Qib | Cov Tshuaj Muaj pes tsawg leeg% | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Re | Lwm tus |

| siab tshaj (≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | —- | 3.5-4.5 | 0.1 | Bal. |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | —- | 4.5-5.3 | 0.1 | Bal. |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | 0.1 | Bal. |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | 0.1 | Bal. |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | 0.1 | Bal. |

| 0Cr21Al4 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 21.0-23.0 | ≤0.60 | 3.0-5.2 | 0.1 | Bal. |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | 0.1 | Bal. |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | 0.1 | Bal. |

![]()

![]()

![]()

![]()

Tshuaj lom neeg muaj pes tsawg leeg thiab cov khoom:

| Khoom/Qib | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | NiCr 35/20 | NiCr 30/20 | |

| Cov Tshuaj Tseem Ceeb Cov khoom xyaw (%) | Ni | Bal. | Bal. | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | Bal. | Bal. | |

| Ua Haujlwm Siab Tshaj Plaws Kub (ºC) | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Kev tiv taus ntawm 20ºC (μΩ · m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Qhov Ceev (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Kev Ua Kub (KJ / m · h · ºC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Coefficient ntawm Thermal Kev nthuav dav (α × 10-6 / ºC) | 18 | 17 | 17 | 19 | 19 | |

| Melting Point (ºC) | 1400 | 1380 xyoo | 1390 xyoo | 1390 xyoo | 1390 xyoo | |

| Kev ntev (%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Cov Qauv Micrographic | austenite | austenite | austenite | austenite | austenite | |

| Khoom Siv Sib Nqus | tsis yog hlau nplaum | tsis yog hlau nplaum | tsis yog hlau nplaum | tsis yog hlau nplaum | tsis yog hlau nplaum | |

![]()

![]()

![]()

![]()

| CuNi Alloys Qib | Kev tiv thaiv hluav taws xob (20 degree Ω) mm² /m2) | coefficient kub ntawm kev tsis kam (10^6/degree) | Qhov Ceev g/mm² | Qhov kub siab tshaj plaws (degree) | Qhov kub yaj (degree) |

| CuNi1 | 0.03 | < 1000 | 8.9 | 200 | 1085 |

| CuNi2 | 0.05 | < 1200 | 8.9 | 200 | 1090 |

| CuNi6 | 0.10 | < 600 | 8.9 | 220 | 1095 |

| CuNi8 | 0.12 | < 570 | 8.9 | 250 | 1097 |

| CuNi10 | 0.15 | < 500 | 8.9 | 250 | 1100 |

| CuNi14 | 0.20 | < 380 | 8.9 | 300 | 1115 |

| CuNi19 | 0.25 | < 250 | 8.9 | 300 | 1135 |

| CuNi22 | 0.30 | < 160 | 8.9 | 300 | 1150 |

| CuNi30 | 0.35 | < 100 | 8.9 | 350 | 1170 |

| CuNi34 | 0.40 | -0 | 8.9 | 350 | 1180 |

| CuNi40 | 0.48 | ± 40 | 8.9 | 400 | 1280 |

| CuNi44 | 0.50 | < -6 | 8.9 | 400 | 1280 |

![]()

![]()

![]()

![]()

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj