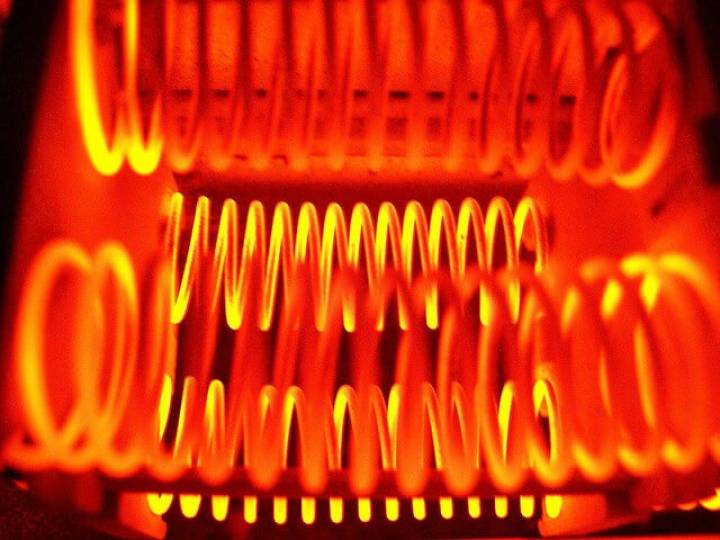

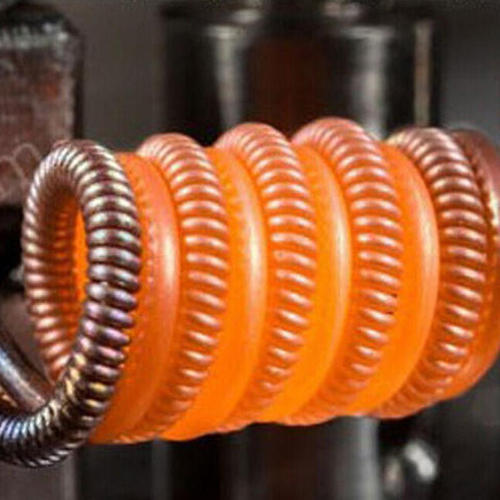

FeCrAl 0Cr25Al5 cua sov qhov cub hluav taws xob hlau cua sov kauj

Cov Khoom Tseem Ceeb ntawm cov cua sov tiv thaiv hlau

| Hom hlau nplaum | Txoj kab uas hla (hli) | Kev tiv taus (μΩm)(20°C) | Tensile Lub zog (N/mm²) | Kev ntev (%) | Khoov Lub Sijhawm | Max.Nruab Nrab Kev Pabcuam Kub (°C) | Lub Neej Ua Haujlwm (teev) |

| Cr20Ni80 | <0.50 | 1.09 ± 0.05 | 850-950 | >20 | >9 | 1200 | >20000 |

| 0.50-3.0 | 1.13 ± 0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| >3.0 | 1.14 ± 0.05 | 850-950 | >20 | >9 | 1200 | >20000 | |

| Cr30Ni70 | <0.50 | 1.18 ± 0.05 | 850-950 | >20 | >9 | 1250 | >20000 |

| ≥0.50 | 1.20 ± 0.05 | 850-950 | >20 | >9 | 1250 | >20000 | |

| Cr15Ni60 | <0.50 | 1.12 ± 0.05 | 850-950 | >20 | >9 | 1125 | >20000 |

| ≥0.50 | 1.15 ± 0.05 | 850-950 | >20 | >9 | 1125 | >20000 | |

| Cr20Ni35 | <0.50 | 1.04 ± 0.05 | 850-950 | >20 | >9 | 1100 | >18000 |

| ≥0.50 | 1.06 ± 0.05 | 850-950 | >20 | >9 | 1100 | >18000 | |

| 1Cr13Al4 | 0.03-12.0 | 1.25 ± 0.08 | 588-735 | >16 | >6 | 950 | >10000 |

| 0Cr15Al5 | 1.25 ± 0.08 | 588-735 | >16 | >6 | 1000 | >10000 | |

| 0Cr25Al5 | 1.42 ± 0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 0Cr23Al5 | 1.35 ± 0.06 | 634-784 | >12 | >5 | 1250 | >8000 | |

| 0Cr21Al6 | 1.42 ± 0.07 | 634-784 | >12 | >5 | 1300 | >8000 | |

| 1Cr20Al3 | 1.23 ± 0.06 | 634-784 | >12 | >5 | 1100 | >8000 | |

| 0Cr21Al6Nb | 1.45 ± 0.07 | 634-784 | >12 | >5 | 1350 xyoo | >8000 | |

| 0Cr27Al7Mo2 | 0.03-12.0 | 1.53±0.07 | 686-784 | >12 | >5 | 1400 | >8000 |

| LUB NPE | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| TSHUAJ TSEEM CEEB | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| COV KHOOM SIV | Re | lub sijhawm zoo | lub sijhawm zoo | lub sijhawm zoo | lub sijhawm zoo | lub sijhawm zoo | lub sijhawm zoo | lub sijhawm zoo |

| Fe | So | So | So | So | So | So | So | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Kub Tshaj Plaws (oC) | 650 | 1250 | 1250 | 1250 | 1100 | 1350 xyoo | 1400 | |

| TSIS TXAUS SIAB20oC (μΩ·m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| KEV CIA (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| KEV SIB HLUA KUB | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| TUS NQI (KJ/m·h·oC) | ||||||||

| tus nqi nthuav dav (α × 10-6 / oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| melting point (oC) | 1450 xyoo | 1500 xyoo | 1500 xyoo | 1500 xyoo | 1500 xyoo | 1510 | 1520 xyoo | |

| lub zog tensile (N / mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| kev ncab (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| kev hloov pauv ntawm thaj chaw (%) | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| zaus khoov (F / R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| qhov nyuaj (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| cov qauv micrographic | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| cov khoom sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | |

| Txoj kab uas hla (hli) | Kev kam rau siab (hli) | Txoj kab uas hla (hli) | Kev kam rau siab (hli) |

| 0.03-0.05 | ±0.005 | >0.50-1.00 | ±0.02 |

| >0.05-0.10 | ±0.006 | >1.00-3.00 | ±0.03 |

| >0.10-0.20 | ±0.008 | >3.00-6.00 | ±0.04 |

| >0.20-0.30 | ±0.010 | >6.00-8.00 | ±0.05 |

| >0.30-0.50 | ±0.015 | >8.00-12.0 | ±0.4 |

| Thickness (hli) | Kev kam rau siab (hli) | Dav (hli) | Kev kam rau siab (hli) |

| 0.05-0.10 | ±0.010 | 5.00-10.0 | ±0.2 |

| >0.10-0.20 | ±0.015 | >10.0-20.0 | ±0.2 |

| >0.20-0.50 | ±0.020 | >20.0-30.0 | ±0.2 |

| >0.50-1.00 | ±0.030 | >30.0-50.0 | ±0.3 |

| >1.00-1.80 | ±0.040 | >50.0-90.0 | ±0.3 |

| >1.80-2.50 | ±0.050 | >90.0-120.0 | ±0.5 |

| >2.50-3.50 | ±0.060 | >120.0-250.0 | ±0.6 |

Peb yog cov chaw tsim khoom ntawm cov xov hlau tiv taus cua sov suav nrog

FeCrAL hlau, NiCr hlau, CuNi hlau:

II Qhov Zoo Tshaj Plaws thiab Daim Ntawv Thov

A. Lub cev tsis zoo:

1) Txoj kab uas hla hlau: 0.025 ~ 15 hli

2) Nickel ntshiab muaj peev xwm tiv taus qhov kub siab heev yam tsis muaj kev puas tsuaj. Kev ua haujlwm siab tshaj plaws

qhov kub yog kwv yees li 600 ° C

3) Cov hlau nickel muaj nyob rau hauv ib txoj hlua lossis ntau txoj hlua. Nws yog muab los ntawm Tshuag los ntawm liab qab, lossis insulated

B. Cov yam ntxwv:

1) Kev ncaj ncees zoo heev

2) Cov xwm txheej zoo nkauj thiab zoo nkauj tsis muaj qhov chaw

3) Muaj peev xwm ua tau zoo heev

C. Cov ntawv thov tseem ceeb thiab lub hom phiaj dav dav:

1) Cov hlau no kuj tseem siv tau dav hauv feem ntau teev rau cov kaus mom transistor, anodes rau cov raj hluav taws xob,

cov xov hlau ntawm cov khoom siv hluav taws xob / cov xov hlau ua rau lub teeb thiab rau cov xov hlau mesh. Kuj siv rau hauv daim ntawv strip rau ntau yam

cov ntawv thov suav nrog Ni-Cd roj teeb

2) Kuj siv rau cov cables, Lead-in-Wire rau teeb, cov khoom siv hluav taws xob, cov xov hlau txuas hluav taws xob

qhov twg qhov kub siab tshaj qhov uas tooj liab haum, kev xaws hlau

3) Cov ntawv thov ib txwm muaj xws li: cov kev xaus rau cov khoom cua sov xws li hauv qhov cub, cov yas extruders, cov cub tawg.

Cov kev txhawb nqa filament thiab cov xov hlau ua rau hauv kev lag luam teeb pom kev zoo

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj