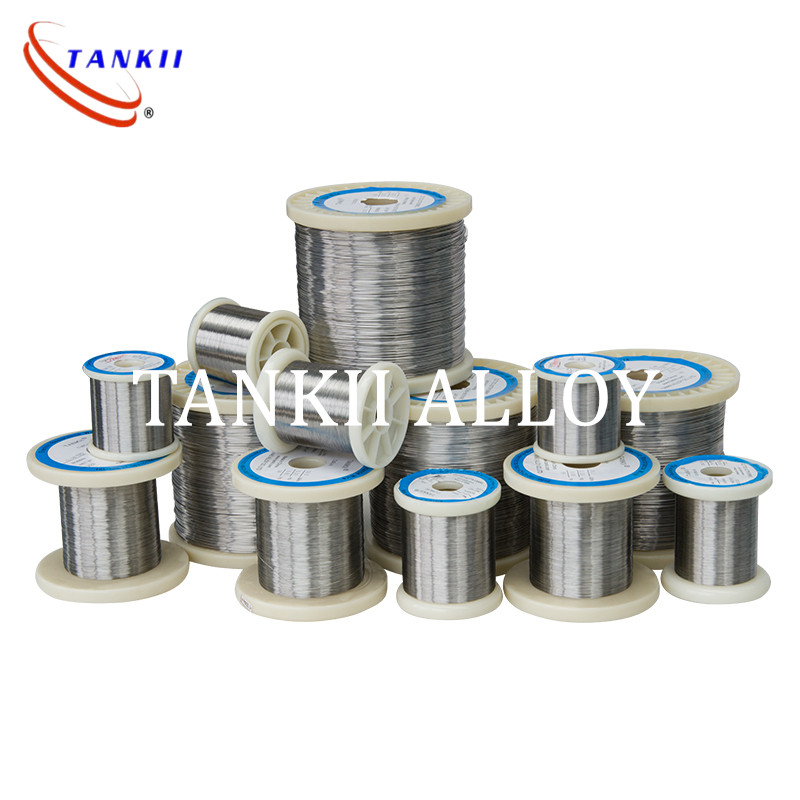

Fecral 135 Alloy Fais Fab Tiv Thaiv Cua Sov Hlau 0cr25al5 0cr23al5 0cr21al6 Rau Cov Coils Cua Sov

FeCrAl 135 Alloy Fais Fab Tiv Thaiv Cua Sov Hlau Ocr25al5 Ocr23al5 Ocr21al6 rau Cov Kauj Rhaub

FeCrAl135 yog ib qho ferritic hlau-chromium-aluminium alloy (FeCrAl alloy) rau kev siv ntawm qhov kub txog li 1300 ° C (2370 ° F). Cov alloy no yog tus cwj pwm los ntawm kev tiv taus siab thiab kev tiv taus oxidation zoo.

FeCrAl135 siv rau hauv cov khoom siv hauv tsev thiab cov cub tawg kev lag luam. Cov ntawv thov ib txwm muaj nyob rau hauv cov khoom siv hauv tsev suav nrog cov hlau sheathed tubular elements rau cov tshuab ntxuav tais diav, cov ntsiab lus embedded nyob rau hauv ceramics rau vaj huam sib luag cua sov, cartridge elements nyob rau hauv hlau dies, cua sov cables thiab hlua cua sov nyob rau hauv defrosting thiab deicing elements, mica elements siv nyob rau hauv irons, quartz tube cua sov rau qhov chaw cua sov, industrial infrared dryers, nyob rau hauv coils ntawm molded ceramic fiber rau boiling plates nrog ceramic hobs, nyob rau hauv bead insulated coils rau vaj huam sib luag cua sov, nyob rau hauv suspended coil elements rau cua sov hauv cov khaub ncaws ziab khaub ncaws.

Hauv cov ntawv thov kev lag luam FeCrAl135 siv rau hauv, piv txwv li, cov davhlau ya nyob twg rau cov khoom siv cua sov, cov khoom siv porcupine rau cua sov, thiab hauv cov khoom siv cua sov.

TSHUAJ TXHUAM XYUAS

| C% | Si% | Mn% | Cr% | Al% | Fe% | |

| Cov qauv tsim tawm | 5.3 | Bal. | ||||

| Tsawg kawg | - | - | - | 23.0 | - | |

| Qhov siab tshaj plaws | 0.05 | 0.5 | 0.45 | 25.0 | - |

COV KHOOM SIV TXUJ CI

| Qhov tuab | Lub zog tawm los | Lub zog tensile | Kev ntev | Qhov nyuaj |

| Rρ0.2 | Rm | A | ||

| mm | Mpa | MPa | % | Hv |

| 2.0 | 450 | 650 | 18 | 200 |

COV KHOOM SIV LUB CEV

| Qhov ceev g/cm3 | 7.15 |

| Hluav taws xob resistivity ntawm 20 ° C Ω mm / m | 1.35 |

| Qhov kub siab tshaj plaws siv °C | 1300 |

| Qhov kub yaj °C | 1500 xyoo |

| Khoom Siv Sib Nqus | Sib nqus |

Qhov kub thiab txias ntawm kev tiv taus

| Kub thiab txias °C | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1300 |

| Ct | 1.00 | 1.01 | 1.01 | 1.02 | 1.03 | 1.03 | 1.04 | 1.04 | 1.04 | 1.05 | 1.05 | 1.05 |

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj