Txais tos rau peb cov vev xaib!

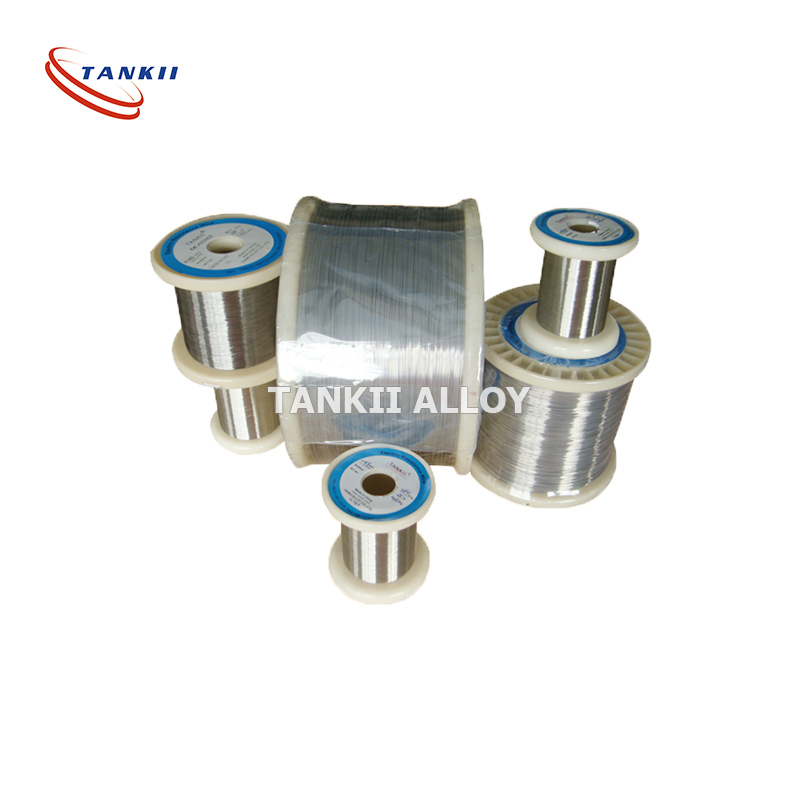

Hlau Hluav Taws Xob Tiv Thaiv Kub SWG 20-32 Mos Annealing Ci FeCrAl CrAl134 FeCrAl125 Fecral Tiv Thaiv Hlau Cua Sov

Hlau Hluav Taws Xob Tiv Thaiv Kub SWG 20-32 Mos Annealing Ci FeCrAl1Cr13Al4Fecral Resistance Cua Sov Hlau

Nta:

- Fecral hluav taws xob tiv taus cua sov alloys nrog hluav taws xob resistivity siab, qhov kub coefficient ntawm kev tiv thaiv yog me me. - Zoo tiv taus corrosion nyob rau hauv qhov kub siab, thiab tshwj xeeb tshaj yog haum rau siv nyob rau hauv cov roj uas muaj sulfur thiab sulfides, tus nqi qis. - Hluav taws xob tiv taus cua sov hlau yog ib hom khoom siv ib txwm ntawm fecral alloy.

Cov ntawv thov:

- Nws yog dav siv hauv kev lag luam cub tawg, khoom siv hauv tsev, kev lag luam cub tawg, metallurgy, machinery, aircraft, automotive,

tub rog thiab lwm yam lag luam tsim cov khoom cua sov thiab cov khoom tiv thaiv.

tub rog thiab lwm yam lag luam tsim cov khoom cua sov thiab cov khoom tiv thaiv.

Qhov Loj Qhov Ntev:

- Hlau: 0.01-10 hli

- Ribbon: 0.05 * 0.2-2.0 * 6.0 hli

- Sawb: 0.05 * 5.0-5.0 * 250 hli

- Bar: 10-50 hli

- Ribbon: 0.05 * 0.2-2.0 * 6.0 hli

- Sawb: 0.05 * 5.0-5.0 * 250 hli

- Bar: 10-50 hli

| Hom Alloy / Kev Ua Tau Zoo | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Kev sau ua ke | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 20.5-23.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.3 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | Lub sijhawm zoo | |||||||

| Fe | So | |||||||

| Nb0.5 | Mo1.8-2.2 | |||||||

| Qhov siab tshaj plaws ntawm kev pabcuam tas mus li ntawm cov khoom (℃) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 xyoo | 1400 | |

| Kev tiv taus ntawm 20 ℃ (μm.m) | 1.25 | 1.42 | 1.42 | 1.35 | 1.23 | 1.45 | 1.53 | |

| Qhov Ceev (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Kev ua kom sov (KJ / mh ℃) | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | – | |

| Coefficient ntawm cov kab nthuav dav (ax10-6 / ℃) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Melting point approx. (℃) | 1450 xyoo | 1500 xyoo | 1500 xyoo | 1500 xyoo | 1500 xyoo | 1510 | 1520 xyoo | |

| Qhov nyuaj (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Kev ntev ntawm kev tawg (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Rov ua dua zaus khoov (F / R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Lub sijhawm pabcuam tas mus li (Teev / ℃) | – | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥80/1350 | ≥80/1350 | |

| Lub zog tensile (N / mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 650-800 | |

| Kev hloov pauv ntawm thaj chaw (%) | 65-75 | 60-75 | 60-75 | 60-75 | 60-75 | 60-75 | 60-75 | |

| Cov Qauv Micrographic | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Cov Khoom Sib Nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | |

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj