Txais tos rau peb cov vev xaib!

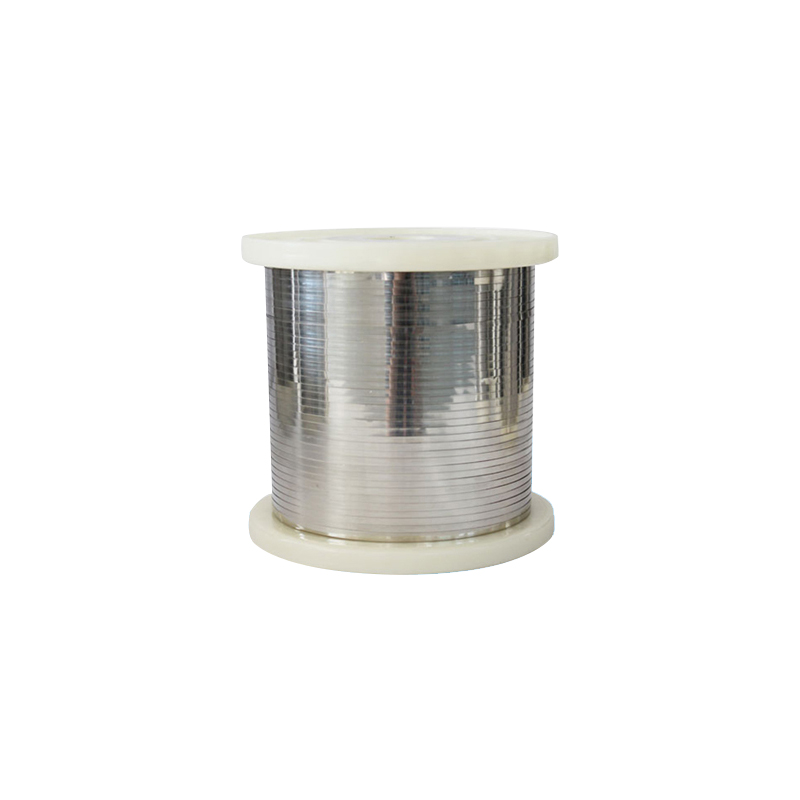

Zoo siab 0.1 hli TK1 FeCrAl Alloy hlau rau cov khoom cua sov hluav taws xob

| Qhov kub ua haujlwm siab tshaj plaws (°C) | 1400 |

| Kev Tiv Thaiv 20 ℃ (Ω / mm2 / m) | 1.48 |

| Qhov Ceev (g/cm³) | 7.1 |

| Kev Ua Kub ntawm 20 ℃, W / (M · K) | 0.49 |

| Cov Coefficient ntawm Kev Nthuav Dav Tawm (× 10¯6 / ℃) 20-1000 ℃) | 16 |

| Kwv yees li ntawm Melting Point (℃) | 1520 xyoo |

| Lub zog tensile (N / mm2) | 680-830 |

| Kev ntev (%) | ›10 |

| Qhov Kev Hloov Pauv ntawm seem Shrink Rate (%) | 65-75 |

| Khoom Siv Sib Nqus | Sib nqus |

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj