Txais tos rau peb cov vev xaib!

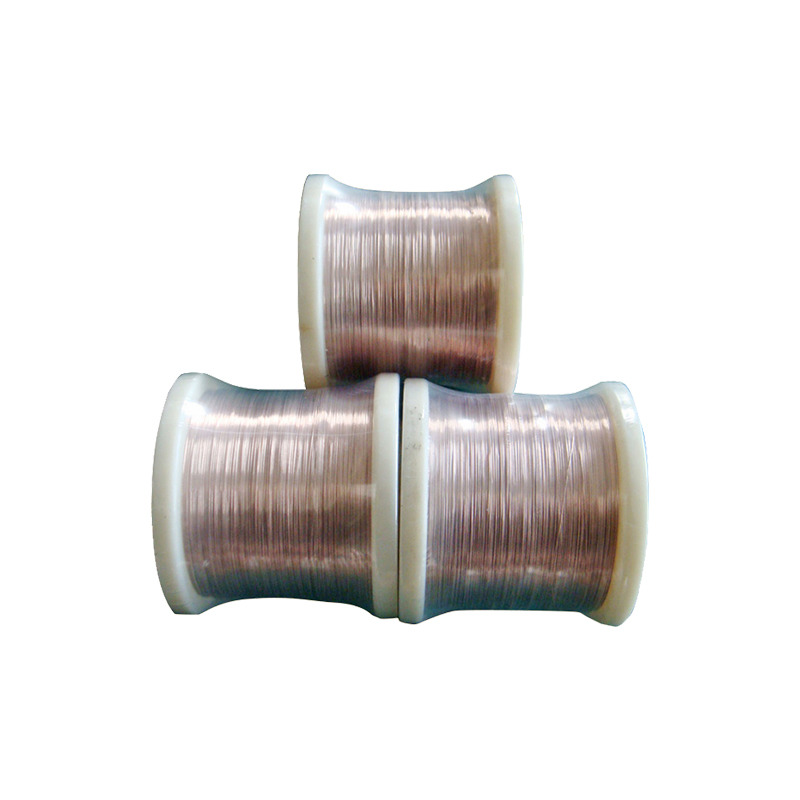

Zoo CuNi Cua Sov Tooj Liab Nickel Alloy CuNi14 Hlau Tiaj Tus Nickel Sawb Hom

Kev piav qhia txog khoom

Qhia txog peb cov Cuni Heating Copper Nickel Alloy CuNi14 Flat Wire Nickel Strip Type zoo tshaj plaws, uas yog ib qho kev daws teeb meem zoo tshaj plaws uas tau tsim los muab kev ua tau zoo tshaj plaws hauv ntau yam kev siv cua sov.

Ua los ntawm kev ua tib zoo, tooj liab no -nickel hlau tiaj tus hlau(CuNi14) muaj cov khoom sib xyaw tshwj xeeb uas sib xyaw ua ke cov thermal conductivity zoo heev ntawm tooj liab nrog rau qhov zoo kawg nkaus corrosion thiab oxidation tsis kam ntawm nickel. Cov qauv hlau tiaj tiaj ua kom muaj kev faib tawm cua sov zoo, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov khoom cua sov uas qhov kub thiab txias sib npaug yog qhov tseem ceeb.

Txawm koj nyob hauv kev lag luam, ua haujlwm rau cov khoom siv hluav taws xob tshwj xeeb, lossis tsim cov tshuab cua sov tshiab, peb cov khoom muaj kev ruaj khov zoo heev. Nws tuaj yeem tiv taus qhov kub thiab txias thiab cov voj voog kub rov ua dua yam tsis muaj kev cuam tshuam rau nws cov qauv lossis kev ua haujlwm.

Cov qauv siv nickel strip ua rau nws muaj kev ntseeg siab ntxiv, muab kev paub txog kev ua kom sov ruaj khov thiab sib xws. Txhim kho koj cov kev daws teeb meem cua sov nrog peb cov khoom zoo tshaj plawsCuNi14 hlau tiaj tusthiab txaus siab rau qhov sib xyaw ua ke zoo meej ntawm qhov zoo, kev ua haujlwm tau zoo, thiab lub neej ntev.

Xaiv peb cov Cuni Heating Copper Nickel Alloy CuNi14 Flat Wire Nickel Strip Type zoo tshaj plaws rau koj qhov project tom ntej thiab paub txog qhov sib txawv uas cov ntaub ntawv zoo tshaj plaws tuaj yeem ua rau koj cov ntawv thov cua sov

| Qib | CuNi1 | CuNi2 | CuNi6 | CuNi8 | CuNi10 | CuNi14 | CuNi19 | CuNi23 | CuNi30 |

| Kub siab tshaj plaws (℃) | 200 | 200 | 220 | 250 | 250 | 300 | 300 | 300 | 350 |

| Qhov Ceev (g/cm3) | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 | 8.9 |

| Kev Tiv Thaiv 20 ℃ (200Cμ. m) | 0.03 ± 10% | 0.05 ± 10% | 0.10 ± 10% | 0.12 ± 10% | 0.15 ± 10% | 0.20 ± 5% | 0.25 ± 5% | 0.30 ± 5% | 0.35 ± 5% |

| Cov coefficient ntawm qhov kub thiab txias x10-6/℃(20-600℃) | <100 | <120 | <60 | <57 | <50 | <38 | <25 | <16 | <10 |

| Lub zog tensile (Mpa) | >210 | >220 | >250 | >270 | >290 | >310 | >340 | >350 | >400 |

| Kev ntev ntawm kev tawg (%) | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 | >25 |

| Qhov chaw sib xyaw (℃) | 1085 | 1090 | 1095 | 1097 | 1100 | 1115 | 1135 | 1150 | 1170 |

| P-tooj liab thermoelectric peev xwm (μV/℃) (0-100℃) | -8 | -12 | -18 | -22 | -25 | -28 | -32 | -34 | -37 |

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj