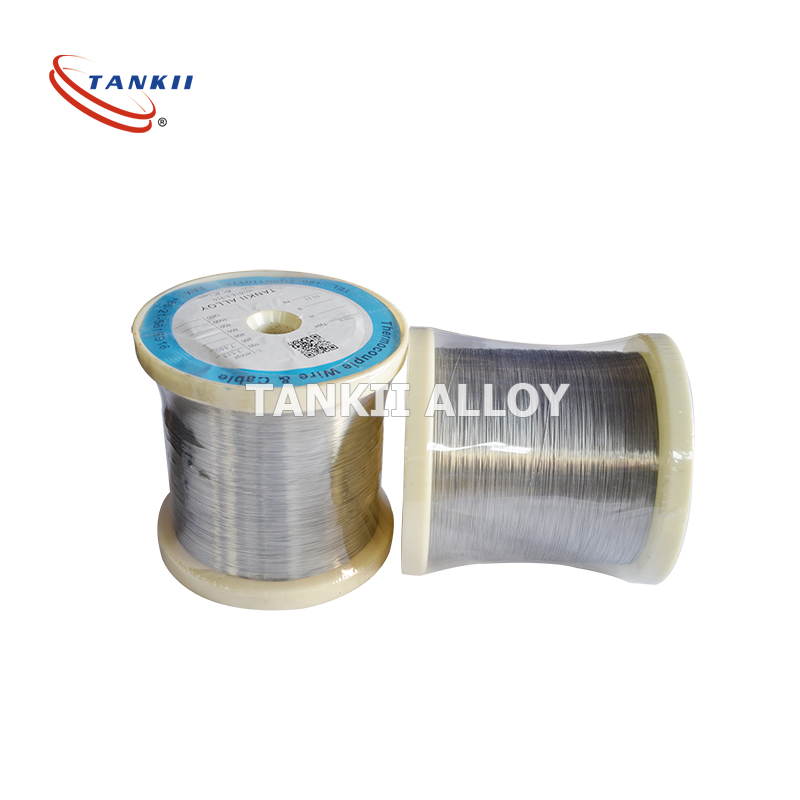

siab tsis kam hluav taws xob cua sov alloy 0Cr19Al3 hlau FeCrAl tsis kam hlau

FeCrAl Cov Khoom Siv Kub 0Cr19Al3

0Cr19Al3

ASTM B603, DIN 17470, JIS C2520, GB / T1234.

Peb qhov kom zoo dua: Zoo, lub sijhawm xa khoom luv luv, MOQ me me.

Cov yam ntxwv: Kev ua haujlwm ruaj khov; Kev tiv thaiv oxidation; Kev tiv thaiv corrosion; Kev ruaj khov kub siab; Muaj peev xwm ua tau zoo heev; Cov xwm txheej zoo nkauj thiab zoo nkauj tsis muaj cov pob.

Siv: Cov khoom siv cua sov tiv taus; Cov khoom siv hauv metallurgy; Cov khoom siv hauv tsev; Kev tsim khoom siv kho tshuab thiab lwm yam lag luam.

Cov Khoom Tseem Ceeb ntawm FeCrAl Fais Fab Tiv Thaiv Cua Sov Hlau

Qhov Loj Ntau:

Hlau: 0.018mm-10mm

Qws: 8mm-50mm

Daim kab xev: 0.05 * 0.2mm-2.0 * 6.0mm

Sawb: 0.5 * 5.0mm-5.0 * 250mm

| Cov khoom siv hlau | Cov tshuaj lom neeg muaj pes tsawg leeg% | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | lwm tus | |

| siab tshaj (≤) | ||||||||||

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | - | 3.5-4.5 | So | - |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | - | 4.5-5.3 | So | - |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | So | - |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | So | - |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | So | - |

| 1Cr20Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | So | - |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | So | Nb ntxiv0.5 |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | So | |

Lwm cov khoom series:

FeCrAl hlau:OCr15Al5,1Cr13Al4, 0Cr21Al4, 0Cr19Al3, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2.

NiCr hlau: Cr20Ni80, Cr30Ni70, Cr20Ni35, Cr20Ni30, Cr15Ni60.

CuNi hlau:NC003, NC010, NC012, NC015, NC020, NC025, NC030, NC040, NC050, Constantan, 6J8/11/12/13/.

Vuam hlau:ERNiCrMo-3/4/13, ERNiCrFe-3/7, ERNiCr-3/7, ERNiCu-7, ERNi-1, ER70S-6.

Cov khoom siv thermocouple:K,J,E,T,N,S,R,B,KX,JX,EX,TX,NX.

Inconel alloy:Inconel 600,601,617, X-750,625,690,718,825.

Incoloy alloy:Incoloy 800,800H, 800HT, 825,925.

Hastelloy alloy:HC-276,C-22,C-4,HB,B/2/3,X,N.

Monel Alloy:Monel 400, K500.

Cov hlau kub siab:A-286, Nimonic80A/90, GH131, GH1140, GH36, GH2706, GH2901, GH3625, GH3536, GH4169.

Precision alloy series:1J33,3J01,3J9,4J29,4J32.4J33,Invar36,4J45.FeNi50.

Cov tshuaj tsuag thermal alloy:Inconel 625, Ni95Al5, Monel400,45CT, HC-276, K500, Cr20Ni80.

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj