Txais tos rau peb cov vev xaib!

Kev Ruaj Ntseg Siab 6J11 Tshiab Constantan Alloy Sawb Haum Rau Kev Tsim Khoom Siv Precision

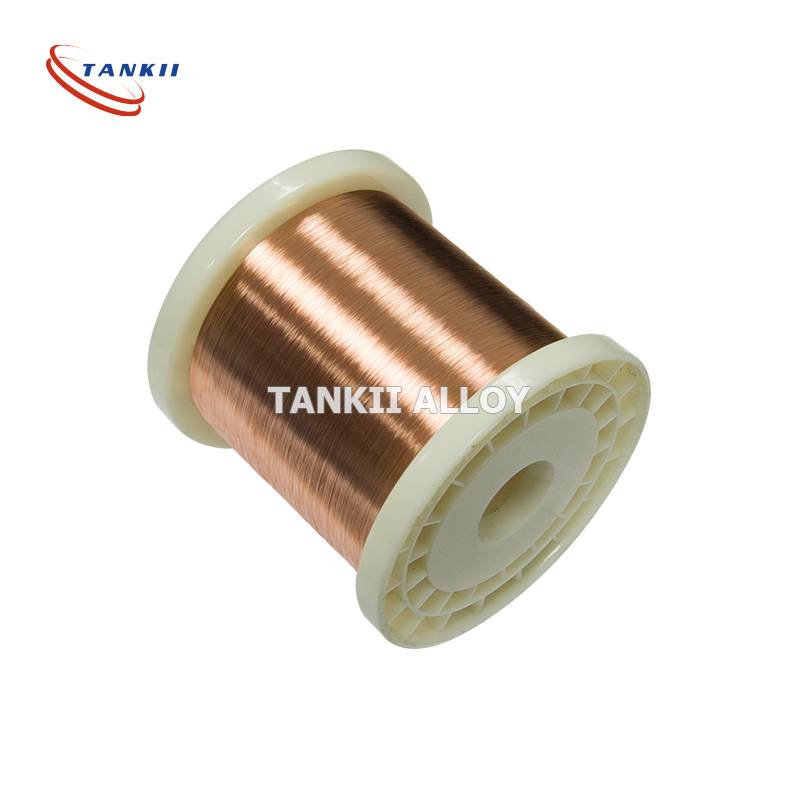

6J11 Constantan Alloy Sawb Tshiab

Txheej Txheem Cej Luam Khoom

6J11 cov hlau nplaum tshiab constantan yog cov khoom siv ua haujlwm siab precision tsis kam ua alloy tsim los ntawm Tankii Alloy Material. Cov hlau nplaum tooj liab-nickel-manganese (Cu-Ni-Mn) no yog qhov zoo tshaj plaws rau cov ntawv thov precision nruab nrab-kub los ntawm kev nqus tsev smelting, ntau-pass precision txias-rolling, thiab tswj cov txheej txheem annealing huab cua.

Cov yam ntxwv tseem ceeb muaj xws li:

- Cov khoom siv hluav taws xob thiab khoom siv kho tshuab ruaj khov hauv 0-120 ℃ kev ua haujlwm ntau yam

- Qhov ceev ntawm 8.5g / cm³ thiab resistivity ntawm 0.49μΩ * m

- Cov coefficient kub tsis kam (TCR)

- Kev tiv thaiv corrosion zoo heev thiab kev ua haujlwm zoo dua

- Zoo tagnrho rau cov resistors precision, current shunts, thiab strain gauges hauv cov khoom siv hluav taws xob, kev tswj hwm kev lag luam, thiab cov tshuab automotive

Cov Qauv Txheem & Lub Hauv Paus Khoom Siv

- Qib Alloy: 6J11 (Tus qauv Suav tshiab constantan alloy qib)

- Cov Khoom Sib Npaug Thoob Ntiaj Teb: Sib piv rau DIN 17471 CuNi44Mn1.5 thiab ASTM B193 hloov kho constantan

- Cov Qauv Tseem Ceeb: 0-120 ℃ kev ua haujlwm ntau yam; qhov ceev 8.5g / cm³; resistivity 0.49μΩ * m (20 ℃)

- Cov Qauv Ua Raws Cai: GB/T 1234-2019, IEC 60404-8-2, thiab RoHS 2.0

- Chaw Tsim Khoom: Tankii Alloy Khoom Siv (ISO 9001 thiab ISO 14001 tau ntawv pov thawj)

Cov txiaj ntsig tseem ceeb

1. Kev Ua Haujlwm Hluav Taws Xob Ruaj Khov Hauv Qhov Nruab Nrab-Kub Ntau Yam

- Kev tiv taus ruaj khov ntawm 0.49μΩ * m (20 ℃)

- TCR qis li ±15 ppm/℃ (0-120 ℃ ntau yam)

- Kev hloov pauv tsis kam <0.008% tom qab 1000 teev ntawm 120 ℃

2. Kev Ua Haujlwm Sib Npaug ntawm Mechanical & Processing

- Qhov ceev ntawm 8.5g/cm³ (12% qis dua li cov hlau nickel-chromium)

- Lub zog tensile 480-550 MPa (lub xeev annealed)

- Kev ntev ≥25% nrog 180 ° bending peev xwm

3. Kev Txhim Kho Corrosion & Kev Hloov Pauv Ib Puag Ncig

- Dhau 1000-teev ASTM B117 kev sim tshuaj tsuag ntsev

- Muaj peev xwm thermoelectric qis (≤2μV / ℃ vs. tooj liab)

- Tiv taus kev xeb hauv huab cua, dej qab zib, thiab cov chaw muaj tshuaj lom neeg me me

Cov Lus Qhia Txog Kev Siv

| Tus cwj pwm | Tus nqi (Ib txwm muaj) | Daim Ntawv Thov Tseem Ceeb |

|---|---|---|

| Cov Tshuaj Lom Zem (wt%) | Cu: 55.0-57.0%; Niag: 41.0-43.0%; Mn: 1.0-2.0% | Cov ntsiab lus Mn tau zoo rau TCR kev ruaj khov |

| Qhov tuab | 0.05-2.0 hli (±0.002 hli rau ≤0.2 hli) | 0.05-0.1 hli rau cov khoom siv hluav taws xob me me |

| Dav | 10-300 hli (±0.1 hli rau ≤100 hli) | 10-50 hli rau cov khoom me me |

| Kev tiv taus (20 ℃) | 0.49μΩ*m (±0.02μΩ*m) | Sib npaug rau 1-10A tam sim no shunts |

| Cov Coefficient Kub | ±15 ppm/℃ (0-120 ℃) | Ua kom muaj kev ruaj khov ntawm kev tiv thaiv |

Cov Lus Qhia Txog Khoom

| Khoom | Cov Lus Qhia Tshwj Xeeb | Kev Ua Haujlwm / Daim Ntawv Thov Qhov Zoo |

|---|---|---|

| Qhov Chaw Tiav | Ci ntsa iab los yog matte tiav | Ci ntsa iab rau kev txiav kom raug; matte rau kev tiv thaiv kev ci ntsa iab |

| Kev tiaj tiaj | ≤0.05 hli / m | Xyuas kom meej tias nws tuab sib npaug |

| Daim Ntawv Muab Khoom | Yob (50m-300m) lossis txiav-rau-ntev (≥50mm) | Yob rau kev tsim khoom loj |

| Kev vuam tau | Haum rau qhov chaw vuam thiab TIG vuam | Kev sib txuas ntawm cov pob qij txha ≤0.1% |

Cov Ntawv Thov Ib Txwm Muaj

- Cov Khoom Siv Hluav Taws Xob Rau Cov Neeg Siv Khoom: Cov micro-current shunts hauv cov adapters them ceev (0.08-0.1mm tuab)

- Cov Txheej Txheem Tsheb: Cov resistors uas ntsuas tam sim no rau cov modules them USB hauv tsheb

- Kev Tswj Xyuas Kev Lag Luam: Cov khoom tiv thaiv rau cov khoom xa tawm siab thiab cov ntsuas ntws

- Cov Khoom Siv Hnav Tau: Cov ntsuas kev ntxhov siab hauv cov ntsuas lub plawv dhia ntse

Kev Tswj Xyuas Zoo

Cov Khoom Siv Tankii Alloy siv cov kev tswj hwm zoo nruj suav nrog:

- Kev tshuaj xyuas cov tshuaj lom neeg ntawm XRF

- Kev ntsuas qhov ntsuas plaub-point probe resistivity siab

- Lub tshuab kuaj universal rau cov khoom siv kho tshuab

- Cov ntaub ntawv qhia txog kev sim khoom siv (MTR) muaj

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj