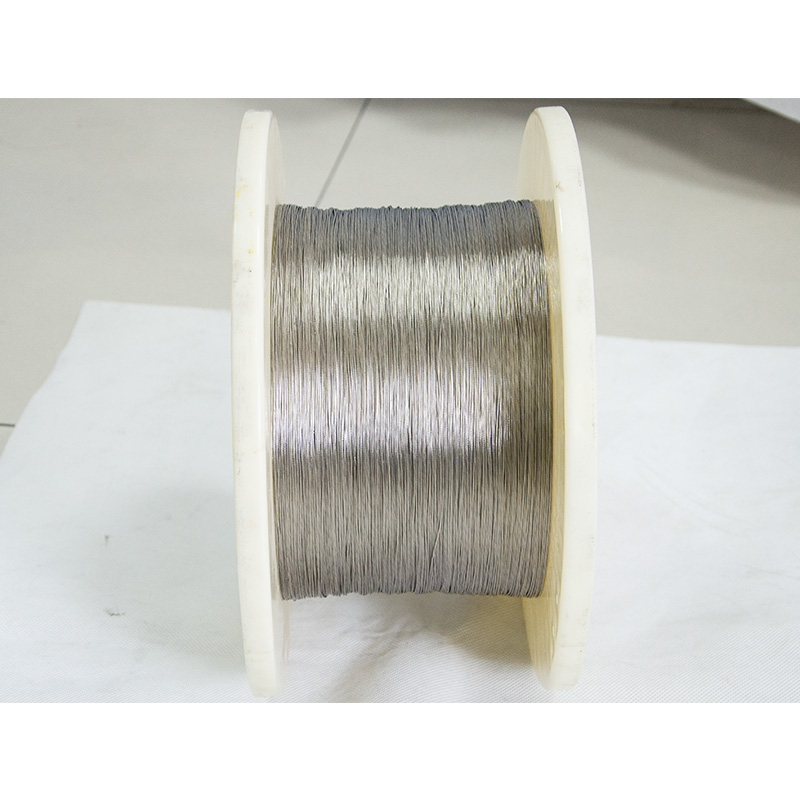

Tus nqi tsim khoom NiCr Alloy Ni35Cr20 Hlau rau Cov Khoom Siv Cua Sov

Kev Taw Qhia Txog Nickel Chromium Alloy:

Nickel Chromium alloy muaj kev tiv taus siab, zoo tiv thaiv oxidation, kub muaj zog, zoo heev daim ntawv ruaj khov thiab weld muaj peev xwm. Nws yog dav siv rau hauv cov khoom siv hluav taws xob cua sov, resistor, industrial furnaces, thiab lwm yam.

Cov Lus Piav Qhia Txog:

Qib: NiCr 35/20 kuj hu ua Chromel D, N4, MWS-610, Stablohm610, Tophet D, Resistohm40, Alloy A, MWS-650, Stablohm 610,

Peb kuj tsim lwm hom nichrome tsis kam hlau, xws li NiCr 70/30, NiCr 60/15, NiCr 60/23, NiCr 37/18, NiCr 35/20, NiCr 35/20, NiCr 25/20, Karma

Tshuaj lom neeg muaj pes tsawg leeg thiab cov khoom:

| Khoom/Qib | NiCr 80/20 | NiCr 70/30 | NiCr 60/15 | NiCr 35/20 | NiCr 30/20 | |

| Cov Tshuaj Lom Zem Tseem Ceeb (%) | Ni | Bal. | Bal. | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | Bal. | Bal. | Bal. | |

| Kub Ua Haujlwm Siab Tshaj (ºC) | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Kev tiv taus ntawm 20ºC | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Qhov Ceev (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Kev Ua Kub | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Cov Coefficient ntawm Thermal Expansion (α × 10-6 / ºC) | 18 | 17 | 17 | 19 | 19 | |

| Melting Point (ºC) | 1400 | 1380 xyoo | 1390 xyoo | 1390 xyoo | 1390 xyoo | |

| Kev ntev (%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Cov Qauv Micrographic | austenite | austenite | austenite | austenite | austenite | |

| Khoom Siv Sib Nqus | tsis yog hlau nplaum | tsis yog hlau nplaum | tsis yog hlau nplaum | tsis yog hlau nplaum | tsis yog hlau nplaum | |

Khoom: Nichrome Strip/Nichrome Daim Kab Xev/Nichrome Ntawv/Nichrome Phaj

Qib: Ni80Cr20 / Resistohm 80 / Chromel A

Cov Tshuaj Muaj Peev Xwm: Nickel 80%, Chrome 20%

Kev tiv taus: 1.09 ohm mm2 / m

Mob: Ci, Annealed, Mos

Nto: BA, 2B, txhuam

Qhov Loj: Dav 1 ~ 470mm, Thickness 0.005mm ~ 7mm

Peb kuj tsim NiCr 60/15, NiCr 38/17, NiCr 70/30, NiCr AA, NiCr 60/23, NiFe80, NiFe50, NiFe42, NiFe36, thiab lwm yam.

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj