Txais tos rau peb cov vev xaib!

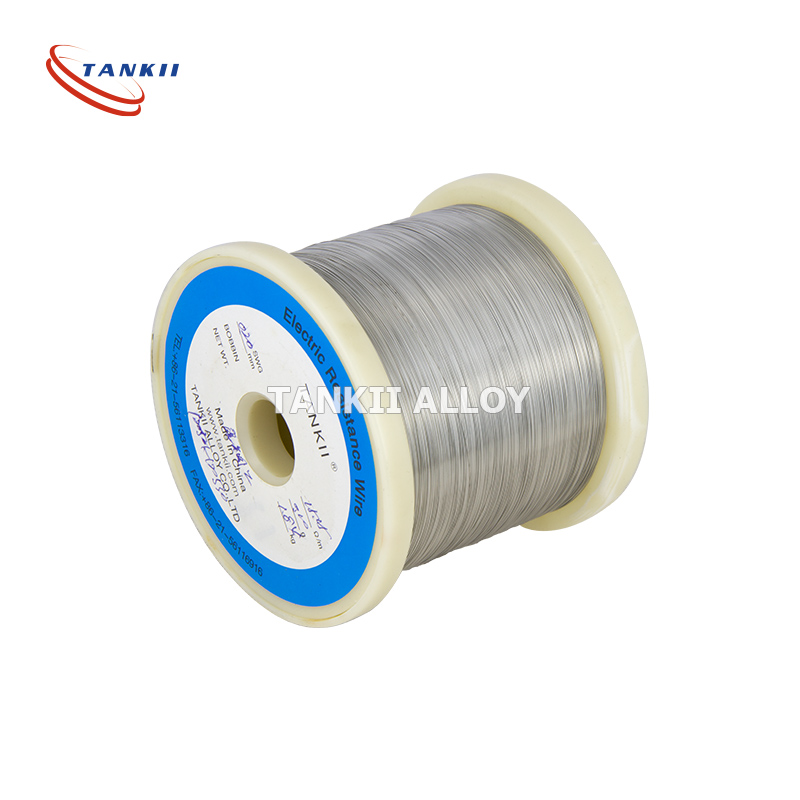

Nch (R) W1 Stranded Nichrome Resistance Wire rau Cua Sov Cable

Nch (R) W1 Stranded Nichrome Resistance Wire rau Cua Sov Cable

Kev piav qhia

| Cov hlau nplaum | Kev Tsim Kho Strand Txheem, hli | Kev tsis kam, Ω / m | Txoj kab uas hla ntawm txoj hlua, mm | Meter ib Kilo |

| NiCr 80/20 | 19 × 0.544 | 0.233-0.269 | 26 | |

| NiCr 80/20 | 19 × 0.61 | 0.205-0.250 | ||

| NiCr 80/20 | 19 × 0.523 | 0.276-0.306 | 2.67 | 30 |

| NiCr 80/20 | 19 × 0.574 | 2.87 | 25 | |

| NiCr 80/20 | 37 × 0.385 | 0.248-0.302 | 2.76 | 26 |

| NiCr 60/15 | 19 × 0.508 | 0.286-0.318 | ||

| NiCr 60/15 | 19 × 0.523 | 0.276-0.304 | 30 | |

| Ni | 19 × 0.574 | 0.020-0.027 | 2.87 | 21 |

Cov ntsiab lus

| Khoom/Qib | Cr20Ni80 | Cr30Ni70 | Cr15Ni60 | Cr20Ni35 | Cr20Ni30 | |

| Cov tshuaj lom neeg tseem ceeb | Ni | So | So | 55.0-61.0 | 34.0-37.0 | 30.0-34.0 |

| Cr | 20.0-23.0 | 28.0-31.0 | 15.0-18.0 | 18.0-21.0 | 18.0-21.0 | |

| Fe | ≤ 1.0 | ≤ 1.0 | So | So | So | |

| Qhov kub siab tshaj plaws ntawm kev pabcuam txuas ntxiv mus ntawm cov khoom | 1200 | 1250 | 1150 | 1100 | 1100 | |

| Kev tiv taus ntawm 20oC (μ Ω · m) | 1.09 | 1.18 | 1.12 | 1.04 | 1.04 | |

| Qhov Ceev (g/cm3) | 8.4 | 8.1 | 8.2 | 7.9 | 7.9 | |

| Kev ua kom sov (KJ / m · h · oC) | 60.3 | 45.2 | 45.2 | 43.8 | 43.8 | |

| Cov coefficient ntawm cov kab nthuav dav (α × 10-6 / oC) | 18 | 17 | 17 | 19 | 19 | |

| Melting point (kwv yees li) (oC) | 1400 | 1380 xyoo | 1390 xyoo | 1390 xyoo | 1390 xyoo | |

| Kev ntev ntawm kev tawg (%) | > 20 | > 20 | > 20 | > 20 | > 20 | |

| Cov qauv micrographic | austenite | austenite | austenite | austenite | austenite | |

| Cov khoom sib nqus | tsis yog hlau nplaum | tsis yog hlau nplaum | tsis yog hlau nplaum | tsis yog hlau nplaum | tsis yog hlau nplaum | |

| Cov Tshuaj Lom Zem | Nickel, Chrome |

| Mob | Xim kaj/Acid dawb/Oxidied |

| Qib | Ni80Cr20, Ni70/30, Ni60Cr15, Ni60Cr23, Ni35Cr20Fe, Ni30Cr20 Ni80, Ni70, Ni60, Ni40, |

| Qhov zoo | Nichrome cov qauv hlau ua rau lawv muaj cov khoom zoo heev thaum txias. |

| Cov yam ntxwv | Kev ua haujlwm ruaj khov; Tiv thaiv kev oxidation; Tiv thaiv kev xeb; Kev ruaj khov kub siab; Muaj peev xwm ua tau zoo heev; Cov xwm txheej zoo nkauj thiab zoo nkauj yam tsis muaj cov pob. |

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj