Cov kev ua tiav zoo ntawm kev lag luam aerospace yog qhov tsis sib cais ntawm kev txhim kho thiab kev tawg ua tej yam hauv kev siv tshuab aerospace. Qhov siab siab, kev ceev ceev thiab kev txav mus los siab ntawm cov dav hlau sib ntaus sib tua xav kom cov khoom siv ntawm lub dav hlau yuav tsum ua kom muaj zog txaus thiab qhov yuav tsum tau ua kom tawv. Cov khoom siv cav yuav tsum ua kom tau raws li qhov xav tau rau kev tiv taus kub siab, cov hlau sib xyaw kub siab, cov khoom sib xyaw ua los ntawm cov av nplaum yog cov khoom siv tseem ceeb.

Cov hlau ib txwm muaj qhov kub siab tshaj 300 ℃, ua rau nws tsis haum rau qhov chaw kub siab. Hauv kev nrhiav kev hloov pauv hluav taws xob zoo dua, qhov kub ua haujlwm siab dua thiab siab dua yog qhov xav tau hauv kev siv lub zog cua sov. Cov hlau alloys kub siab tau tsim los rau kev ua haujlwm ruaj khov ntawm qhov kub siab tshaj 600 ℃, thiab cov thev naus laus zis txuas ntxiv mus.

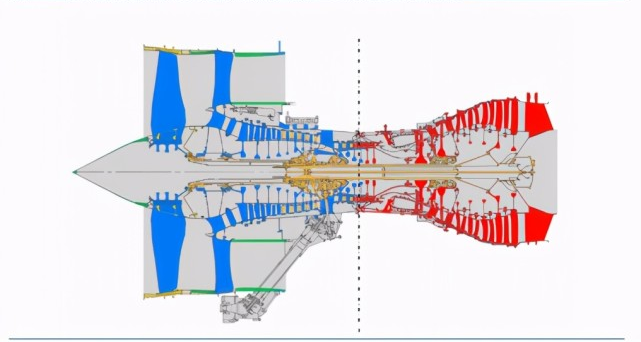

Cov hlau sib xyaw kub siab yog cov khoom siv tseem ceeb rau cov cav aerospace, uas tau muab faib ua cov hlau sib xyaw kub siab, nickel-raws li cov ntsiab lus tseem ceeb ntawm cov hlau sib xyaw. Cov hlau sib xyaw kub siab tau siv rau hauv cov cav aerospace txij li thaum lawv pib, thiab yog cov khoom siv tseem ceeb hauv kev tsim cov cav aerospace. Qib kev ua tau zoo ntawm lub cav nyob ntawm qib kev ua tau zoo ntawm cov khoom siv hlau sib xyaw kub siab. Hauv cov cav aerospace niaj hnub no, qhov ntau ntawm cov khoom siv hlau sib xyaw kub siab suav txog 40-60 feem pua ntawm tag nrho qhov hnyav ntawm lub cav, thiab feem ntau yog siv rau plaub lub ntsiab lus kub-kawg: chav sib xyaw, cov lus qhia, cov hniav turbine thiab cov discs turbine, thiab ntxiv rau, nws yog siv rau cov khoom xws li cov ntawv xov xwm, cov nplhaib, chav sib xyaw kub thiab cov nozzles tail.

(Daim duab liab qhia txog cov hlau kub siab)

Cov hlau sib xyaw ua los ntawm nickel uas kub heev Feem ntau ua haujlwm ntawm 600 ℃ saum toj no qee qhov kev ntxhov siab, nws tsis tsuas yog muaj kev tiv thaiv oxidation thiab corrosion zoo hauv qhov kub thiab txias, tab sis kuj muaj lub zog kub thiab txias, lub zog nkag thiab lub zog ua haujlwm ntev, thiab kuj tiv taus qaug zog zoo. Feem ntau siv rau hauv kev lag luam aerospace thiab aviation hauv qab qhov kub thiab txias, cov khoom siv hauv paus, xws li cov hniav dav hlau, cov discs turbine, cov chav sib txuas thiab lwm yam. Cov hlau kub nickel raws li cov hlau kub tuaj yeem faib ua cov hlau kub deformed, cov hlau kub casting thiab cov hlau kub tshiab raws li cov txheej txheem tsim khoom.

Vim tias qhov kub ua haujlwm ntawm cov hlau uas tiv taus cua sov siab dua thiab siab dua, cov ntsiab lus ntawm cov hlau no ua rau muaj zog ntau dua thiab ntau dua, cov khoom sib xyaw ua ke ntau dua, ua rau qee cov hlau tsuas yog siv tau rau hauv lub xeev cam khwb cia, thiab tsis tuaj yeem hloov pauv los ntawm kev ua haujlwm kub. Ntxiv mus, qhov nce ntawm cov ntsiab lus ntawm cov hlau ua rau cov hlau nickel khov nrog kev sib cais loj ntawm cov khoom, ua rau tsis sib xws ntawm lub koom haum thiab cov khoom.Kev siv cov txheej txheem hmoov metallurgy los tsim cov alloys kub siab, tuaj yeem daws cov teeb meem saum toj no.Vim yog cov hmoov me me, cov hmoov txias sai, tshem tawm kev sib cais, txhim kho kev ua haujlwm kub, cov hlau qub casting rau hauv cov hlau kub ua haujlwm tau deformation, cov khoom tsim tau zoo dua thiab qaug zog, hmoov hlau kub siab rau kev tsim cov hlau muaj zog dua tau tsim txoj hauv kev tshiab.

Lub sijhawm tshaj tawm: Lub Ib Hlis-19-2024