Txais tos rau peb cov vev xaib!

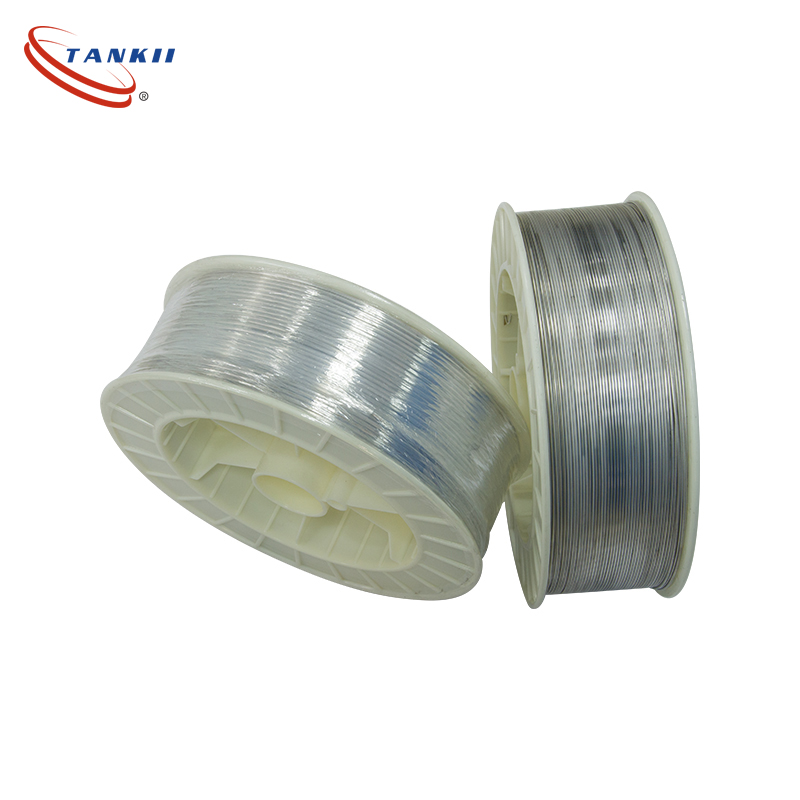

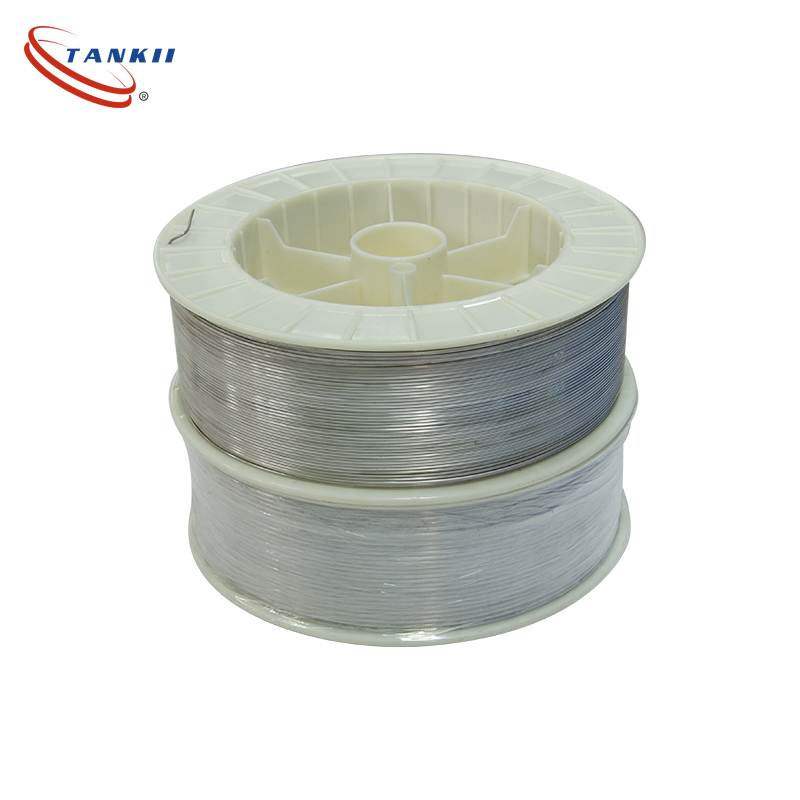

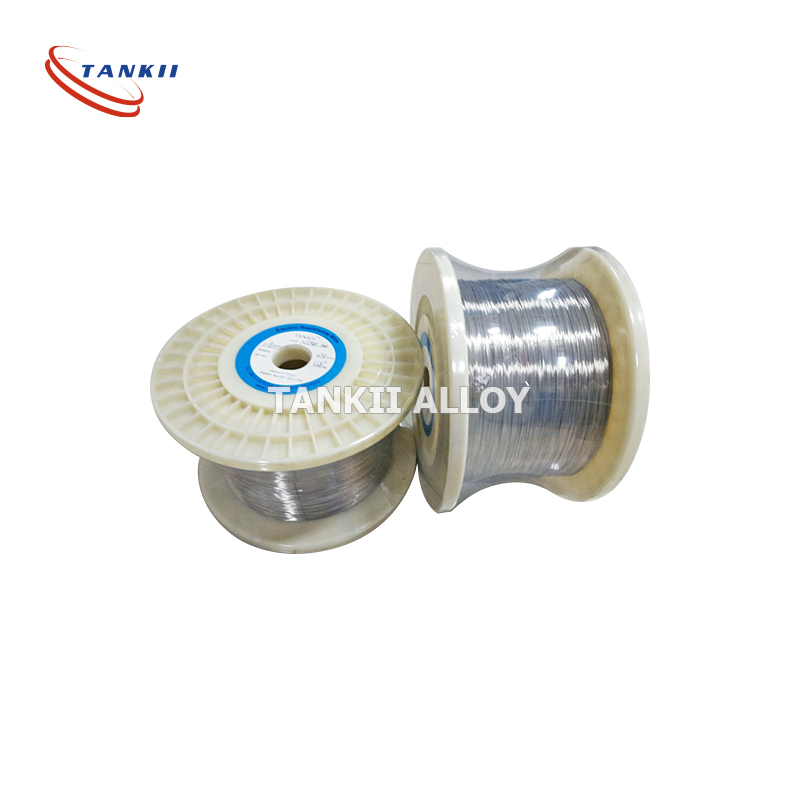

Ni95Al5 Thermal Spray Wire / 955 Nickel-Aluminium Bond Coat Wire

Lub Npe Khoom

Ni95Al5 Thermal Spray Wire / 955 Nickel-Aluminium Bond Coat Wire

Qib / Sib npaug

NiAl 955, Ni95Al5, TAFA 75B, PMET 885, MEC 885

NiAl 955, Ni95Al5, TAFA 75B, PMET 885, MEC 885

Cov Khoom Siv Hlau (wt%)

Ni ≥ 95 | Al 4-5 | C ≤ 0.02 | Mn ≤ 0.2 | Si ≤ 0.2 | Fe ≤ 0.5 | O ≤ 0.005 | Lwm tus ≤ 0.5

Ni ≥ 95 | Al 4-5 | C ≤ 0.02 | Mn ≤ 0.2 | Si ≤ 0.2 | Fe ≤ 0.5 | O ≤ 0.005 | Lwm tus ≤ 0.5

Muaj Qhov Loj & Kev kam rau siab

1.6 hli (-0 / +0.05 hli) | 2.0 hli (-0 / +0.05 hli)

Lwm qhov ntau thiab tsawg raws li qhov kev thov.

1.6 hli (-0 / +0.05 hli) | 2.0 hli (-0 / +0.05 hli)

Lwm qhov ntau thiab tsawg raws li qhov kev thov.

Cov Khoom Siv Lub Cev thiab Cov Tshuaj Tsuag Ib Txwm Muaj

- Qhov Ceev: 8.83 g cm⁻³

- Kev ntev: 40%

- Kub siab tshaj plaws: 1 300 °C (lub sijhawm luv luv 1 390 °C)

- Qhov nyuaj thaum txau: 200-260 HV

- Lub zog sib txuas ntawm cov hlau tsis muaj zog: ≥ 55 MPa

- Cov ntsiab lus oxide tom qab txau: ≤ 3%

- Qhov tiav ntawm qhov chaw: ci ntsa iab, du, tsis muaj kos cim

Cov yam ntxwv ntawm cov txheej txheem tseem ceeb

✔ Cov qauv me me uas tuab heev, porosity < 2%

✔ Kev sib txuas tus kheej rau feem ntau cov hlau & nickel-base substrates (tsis tas yuav muaj txheej nruab nrab)

✔ Tsim cov nplai Al₂O₃ hauv qhov chaw → zoo heev rau kev ua kom sov siab thiab tiv taus xeb

✔ Zoo heev thermal-shock & scuff tsis kam

✔ Cov qauv me me uas tuab heev, porosity < 2%

✔ Kev sib txuas tus kheej rau feem ntau cov hlau & nickel-base substrates (tsis tas yuav muaj txheej nruab nrab)

✔ Tsim cov nplai Al₂O₃ hauv qhov chaw → zoo heev rau kev ua kom sov siab thiab tiv taus xeb

✔ Zoo heev thermal-shock & scuff tsis kam

Cov Kev Ntsuas Tshuaj Tsuag Pom Zoo (Arc-Spray)

Lub zog hluav taws xob: 30-34 V | Tam sim no: 120-180 A | Lub zog cua: 0.55-0.65 MPa

Qhov nrug ntawm kev sawv ntsug: 150-200 hli | Kev khiav ceev: 200-400 hli s⁻¹

Lub zog hluav taws xob: 30-34 V | Tam sim no: 120-180 A | Lub zog cua: 0.55-0.65 MPa

Qhov nrug ntawm kev sawv ntsug: 150-200 hli | Kev khiav ceev: 200-400 hli s⁻¹

Cov Ntawv Thov Tseem Ceeb

- Cov txheej txheem nplaum rau cov txheej txheem saum toj kawg nkaus ntawm cov av nplaum (ZrO₂, Al₂O₃, Cr₂O₃) ntawm cov hniav roj-turbine, cov pas nrig piston, thiab cov raj boiler

- Txheej hauv qab uas tiv taus xeb rau cov kav dej tshuaj, cov kiv cua impellers, thiab cov kiv cua marine

- Kev kho dua tshiab ntawm cov pwm iav uas siv lawm, cov pwm forging, cov yob ziab ntawv

- EMI shielding & conductive coatings hauv electronic housings

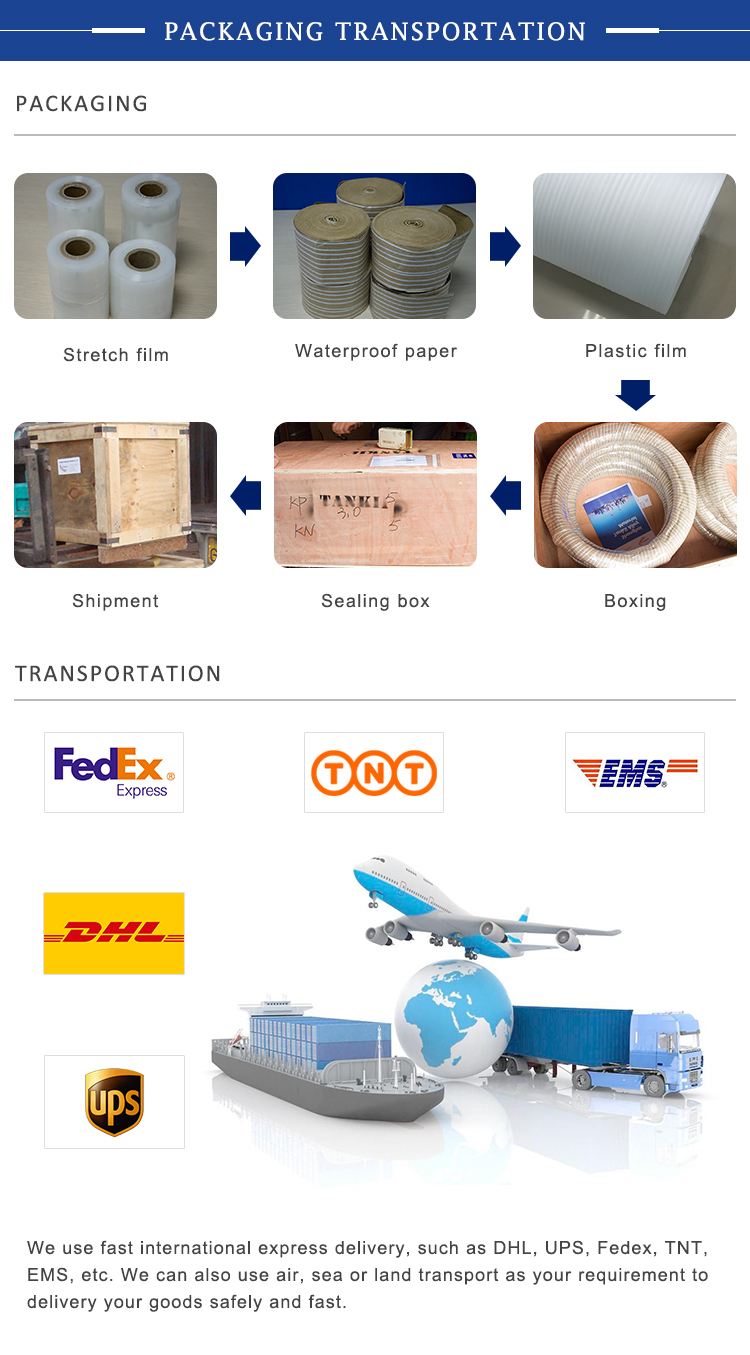

Cov Kev Xaiv Ntim Khoom

- 15 kg / 25 kg yas spool (DIN 300) + ntawv ci nqus tsev + thawv xa khoom

- 50-250 kg hlau kauj, PE-qhwv + ntoo pallet

- Kev cai labeling & bar-coding muaj

Kev Ua Raws Cai ntawm Cov Qauv

AMS 4778, ASTM B833, ISO 14919, GB/T 30566

AMS 4778, ASTM B833, ISO 14919, GB/T 30566

Lub Neej Khaws Cia & Kev Khaws Cia

5 xyoos nyob rau hauv lub thawv qub uas tsis tau qhib; khaws cia <25 °C, RH < 60%, deb ntawm cov kua qaub thiab sulfur.

5 xyoos nyob rau hauv lub thawv qub uas tsis tau qhib; khaws cia <25 °C, RH < 60%, deb ntawm cov kua qaub thiab sulfur.

MOQ & Lub Sijhawm Ua Ntej

15 kg; 3-5 hnub ex-hoobkas rau ≤ 500 kg, 7-10 hnub rau ≤ 2 t.

15 kg; 3-5 hnub ex-hoobkas rau ≤ 500 kg, 7-10 hnub rau ≤ 2 t.

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj