Nicr6015 / Chromel C / Nikrothal 60 Tiaj Nicr Alloy

Nicr6015 / Chromel C / Nikrothal 60 Tiaj Nicr Alloy

Lub npe nrov:

Ni60Cr15, kuj hu ua Chromel C, N6, HAI-NiCr 60, Tophet C, Resistohm 60, Cronifer II, Electroloy, Nichrome, Alloy C, MWS-675, Stablohm 675, NiCrC.

Ni60Cr15 yog ib qho hlau nickel-chromium alloy (NiCr alloy) uas muaj cov yam ntxwv zoo xws li kev tiv taus siab, kev tiv taus oxidation zoo, kev ruaj khov zoo thiab kev ua haujlwm zoo thiab kev vuam zoo heev. Nws tsim nyog siv rau qhov kub txog li 1150 ° C.

Cov ntawv thov ib txwm rau Ni60Cr15 yog siv rau hauv cov hlau sheathed tubular elements, piv txwv li, cov phaj kub,

cov hniav nyiaj hniav kub, cov qhov cub ci mov thiab cov cua sov cia khoom. Cov hlau nplaum kuj tseem siv rau cov kauj vuam uas raug tshem tawm hauv cov cua sov hauv cov tshuab ziab khaub ncaws, cov cua sov kiv cua, cov tshuab ziab tes thiab lwm yam.

Cov Ntsiab Lus Tshuaj (%)

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Lwm yam |

| Qhov siab tshaj plaws 0.08 | Siab tshaj plaws 0.02 | Qhov siab tshaj plaws 0.015 | Siab tshaj plaws 0.6 | 0.75-1.6 | 15-18 | 55-61 | Siab tshaj 0.5 | Bal. | - |

![]()

![]()

![]()

![]()

Cov Khoom Siv Kho Tshuab

| Kub Tshaj Plaws Kev Pabcuam Txuas Ntxiv Mus | 1150°C |

| Kev Tiv Thaiv 20 ° C | 1.12 ohm hli2/m |

| Qhov Ceev | 8.2 g/cm33 |

| Kev Ua Kub | 45.2 KJ/mh°C |

| Coefficient ntawm Thermal Expansion | 17 * 10-6(20°C~1000°C) |

| Qhov Kub Yaj | 1390°C |

| Kev ntev | MIn 20% |

| Khoom Siv Sib Nqus | tsis yog hlau nplaum |

![]()

![]()

![]()

![]()

Cov Yam Kub thiab Txias ntawm Cov Hluav Taws Xob Resistivity

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 500ºC | 600ºC |

| 1 | 1.011 | 1.024 | 1.038 | 1.052 | 1.064 | 1.069 |

| 700ºC | 800ºC | 900ºC | 1000ºC | 1100ºC | 1200ºC | 1300ºC |

| 1.073 | 1.078 | 1.088 | 1.095 | 1.109 | - | - |

![]()

![]()

![]()

![]()

Qhov zoo ntawm NICR6015 tsis kam hlau feem ntau suav nrog cov hauv qab no:

1. Kev ruaj khov kub: NICR6015 hlau tsis kam siv tau rau hauv qhov chaw kub siab hauv qab 1000ºC, thiab muaj kev ruaj khov kub zoo.

2. Kev tiv thaiv corrosion: NICR6015 tsis kam hlau muaj kev tiv thaiv corrosion zoo thiab siv tau rau hauv cov xov xwm corrosive xws li acids thiab alkalis.

3. Cov khoom siv kho tshuab zoo: NICR6015 tsis kam hlau muaj lub zog siab thiab tawv, cov khoom siv kho tshuab zoo, thiab tsis yooj yim rau deform.

4. Kev coj ua zoo: NICR6015 tsis kam hlau muaj qhov tsis kam thiab kev coj ua siab, thiab tuaj yeem muab cov zis hluav taws xob loj hauv qab qhov hluav taws xob me me.

5. Yooj yim rau kev ua tiav: NICR6015 tsis kam hlau yog yooj yim rau kev ua tiav rau hauv ntau yam duab thiab qhov ntau thiab tsawg kom tau raws li qhov xav tau ntawm ntau daim ntawv thov.

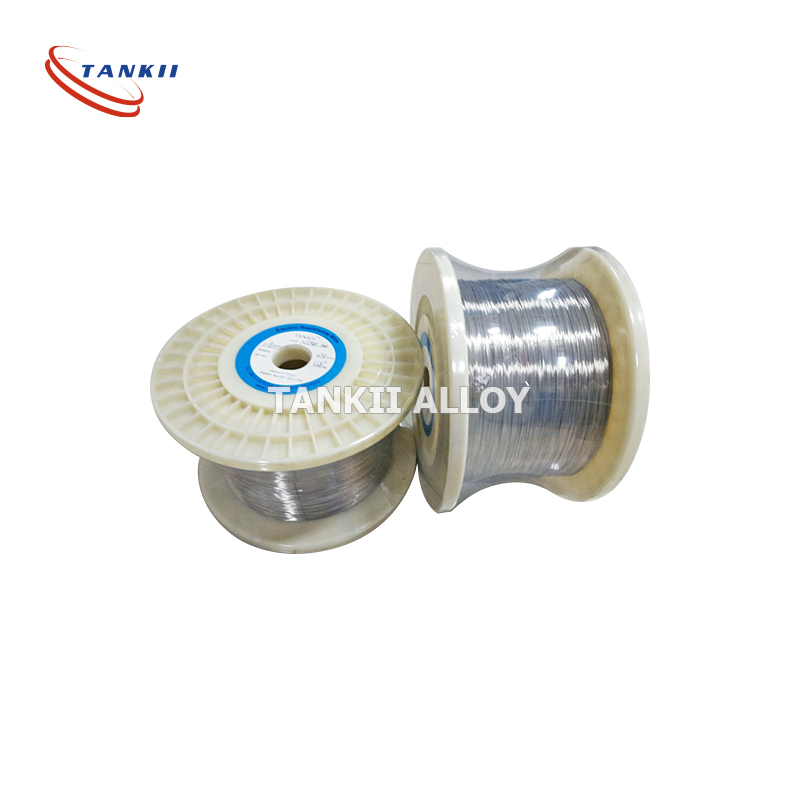

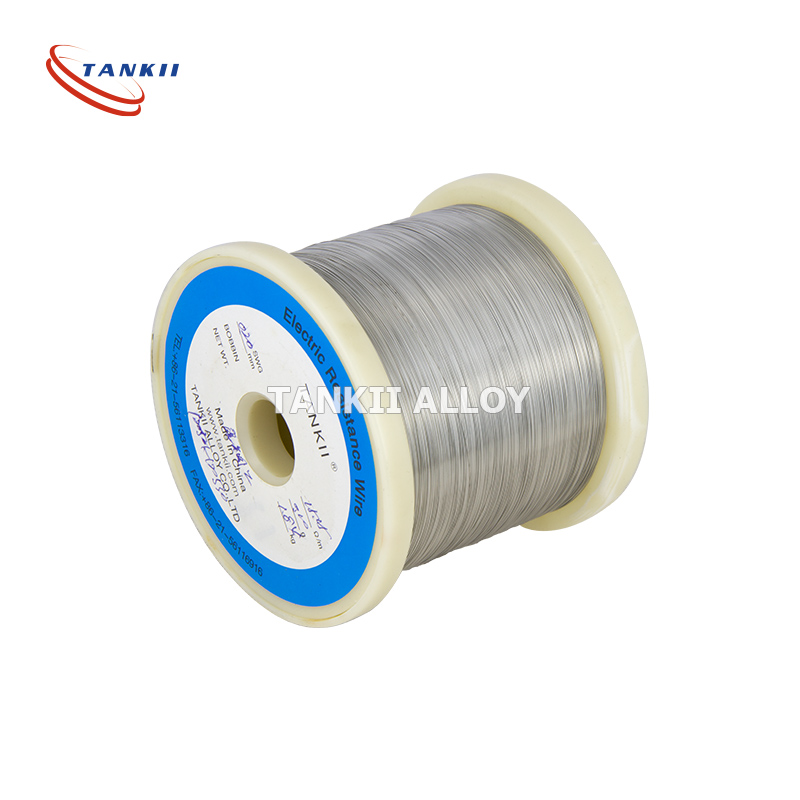

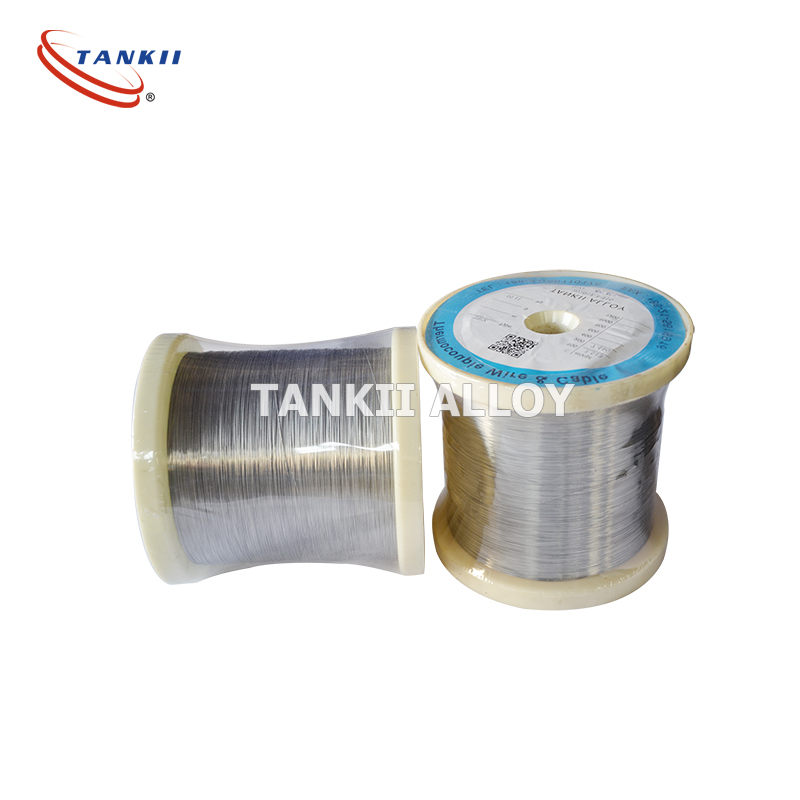

Loj Li Qub:

Peb muab cov khoom lag luam zoo li hlau, hlau tiaj tus, thiab daim kab xev. Peb kuj tuaj yeem ua cov khoom siv raws li cov neeg siv khoom thov.

Hlau ci thiab dawb - 0.03mm ~ 3mm

Hlau pickling: 1.8mm ~ 8.0mm

Hlau oxidized: 3mm ~ 8.0mm

Hlau tiaj tus: tuab 0.05mm ~ 1.0mm, dav 0.5mm ~ 5.0mm

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj