OCr21AI4 (214), FCHW-2 Fecral Cua Sov Hlau rau Cua Sov

OCr21AI4 (214),FCHW-2 FeCrAl Cua Sov Hlau rau Cua Sov

0Cr21Al4

Cov Ntaub Ntawv Dav Dav

FeCrAl, ib tsev neeg ntawm cov hlau-chromium-aluminium alloys (Kanthal APM, A-1, D thiab AF thiab lwm yam) siv rau hauv ntau yam kev tiv thaiv thiab kev siv kub siab kuj siv rau hauv daim ntawv ntawm cov xov hlau tiv thaiv.

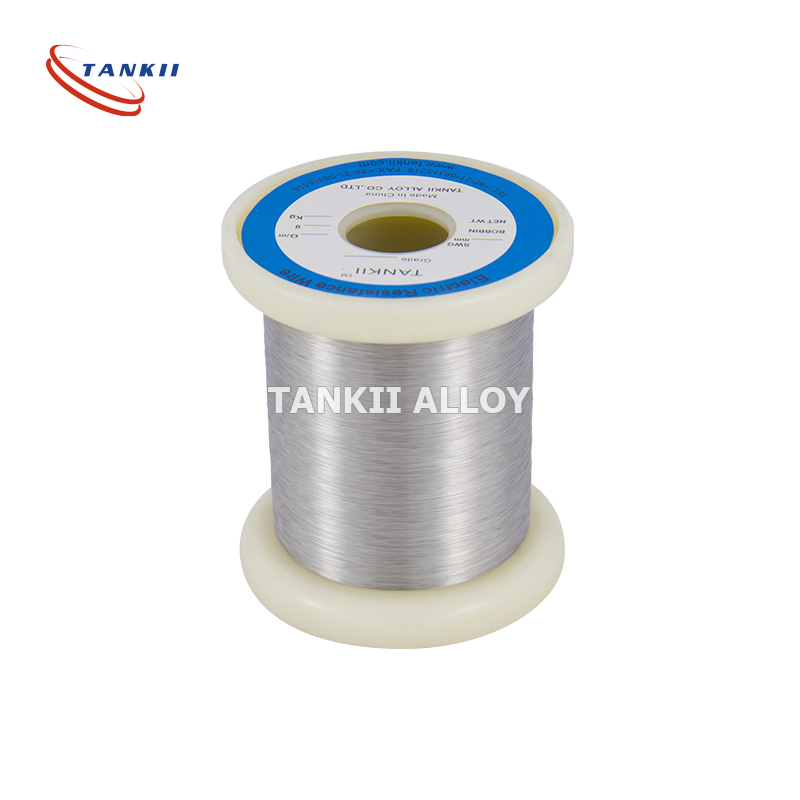

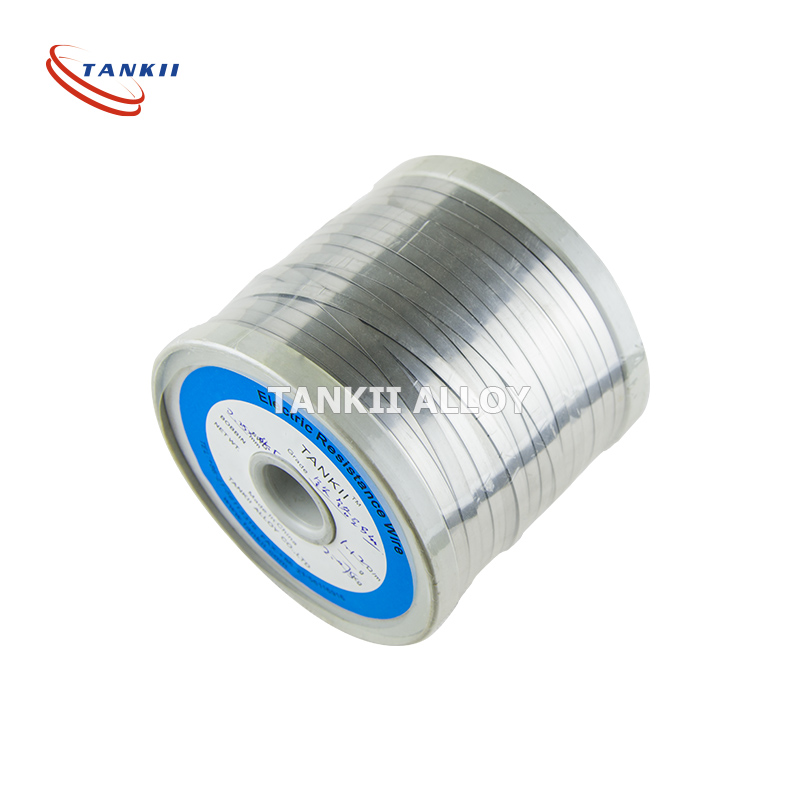

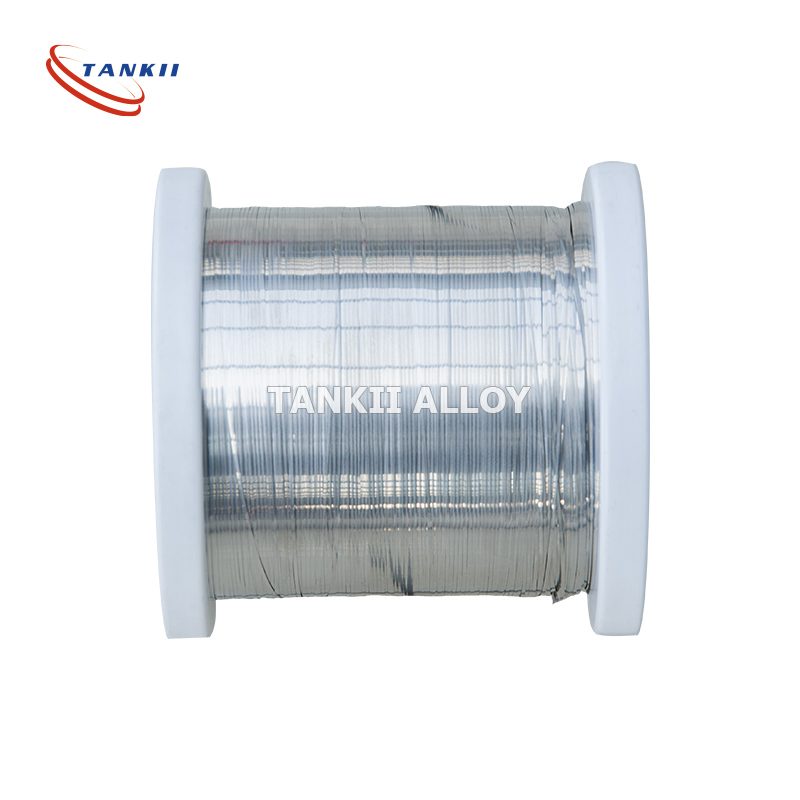

Lub Npe: cua sov hlau

xim: oxidized los yog ci ntsa iab

Pob: Lub thawv ntawv lossis rooj ntoo raws li xav tau

Daim Ntawv Thov: ua cov khoom siv cua sov xws li lub cub tawg, cov khoom siv cua sov pej xeem, ntau yam hluav taws xob resistors thiab locomotive braking resistor

Qhov chaw ntawm keeb kwm: Jiangsu, Suav teb (Mainland)

| Lub Npe | Cov Cheebtsam | |||||||

| Ni | Fe | Zn | Mn | Cu | AI | Cr | Si | |

| NCHW-1 | 77 feeb | 2.5 Siab Tshaj | 19~21 | 0.75~1.5 | ||||

| NCHW-2 | 57 feeb | 1.5 Siab Tshaj | 15~18 | 0.75~1.5 | ||||

| FCHW-1 | rem | 1.0 Siab Tshaj | 4.0~6.0 | 23~26 | 1.5 Feeb | |||

| FCHW-2 | rem | 1.0 Siab Tshaj | 2.0~4.0 | 17~22 | 1.5 Feeb | |||

Kev Siv: Resistor

Loj: Thickness 0.01-7mm, dav 1mm-1000mm

Nto: BA, 2B

| Cov khoom siv hlau | Cov tshuaj lom neeg muaj pes tsawg leeg% | |||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | lwm tus | |

| siab tshaj (≤) | ||||||||||

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.60 | 20.0-23.0 | So | ≤0.50 | ≤1.0 | - |

| Cr30Ni70 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.60 | 28.0-31.0 | So | ≤0.50 | ≤1.0 | - |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.60 | 15.0-17.0 | 55.0- 61.0 | ≤0.50 | So | - |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1 | 1.00-3.00 | 18.0-21.0 | 34.5-36.0 | - | So | - |

| Cr20Ni30 | 0.08 | 0.02 | 0.015 | 1 | 1.00-2.00 | 18.0-21.0 | 30.0-31.5 | - | So | - |

| 1Cr13Al4 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 12.5-15.0 | - | 3.5-4.5 | So | - |

| 0Cr15Al5 | 0.12 | 0.025 | 0.025 | 0.7 | ≤1.00 | 14.5-15.5 | - | 4.5-5.3 | So | - |

| 0Cr25Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 23.0-26.0 | ≤0.60 | 4.5-6.5 | So | - |

| 0Cr23Al5 | 0.06 | 0.025 | 0.025 | 0.7 | ≤0.60 | 20.5-23.5 | ≤0.60 | 4.2-5.3 | So | - |

| 0Cr21Al6 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 19.0-22.0 | ≤0.60 | 5.0-7.0 | So | - |

| 1Cr20Al3 | 0.06 | 0.025 | 0.025 | 0.7 | ≤1.00 | 18.0-21.0 | ≤0.60 | 3.0-4.2 | So | - |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.025 | 0.7 | ≤0.60 | 21.0-23.0 | ≤0.60 | 5.0-7.0 | So | Nb ntxiv0.5 |

| 0Cr27Al7Mo2 | 0.05 | 0.025 | 0.025 | 0.2 | ≤0.40 | 26.5-27.8 | ≤0.60 | 6.0-7.0 | So | |

nyob rau hauv daim ntawv ntawm hlau, ribbon thiab strip

Hlau: 0.018mm-10mm

Daim kab xev: 0.05 * 0.2mm-2.0 * 6.0mm

Sawb: 0.5 * 5.0mm-5.0 * 250mm

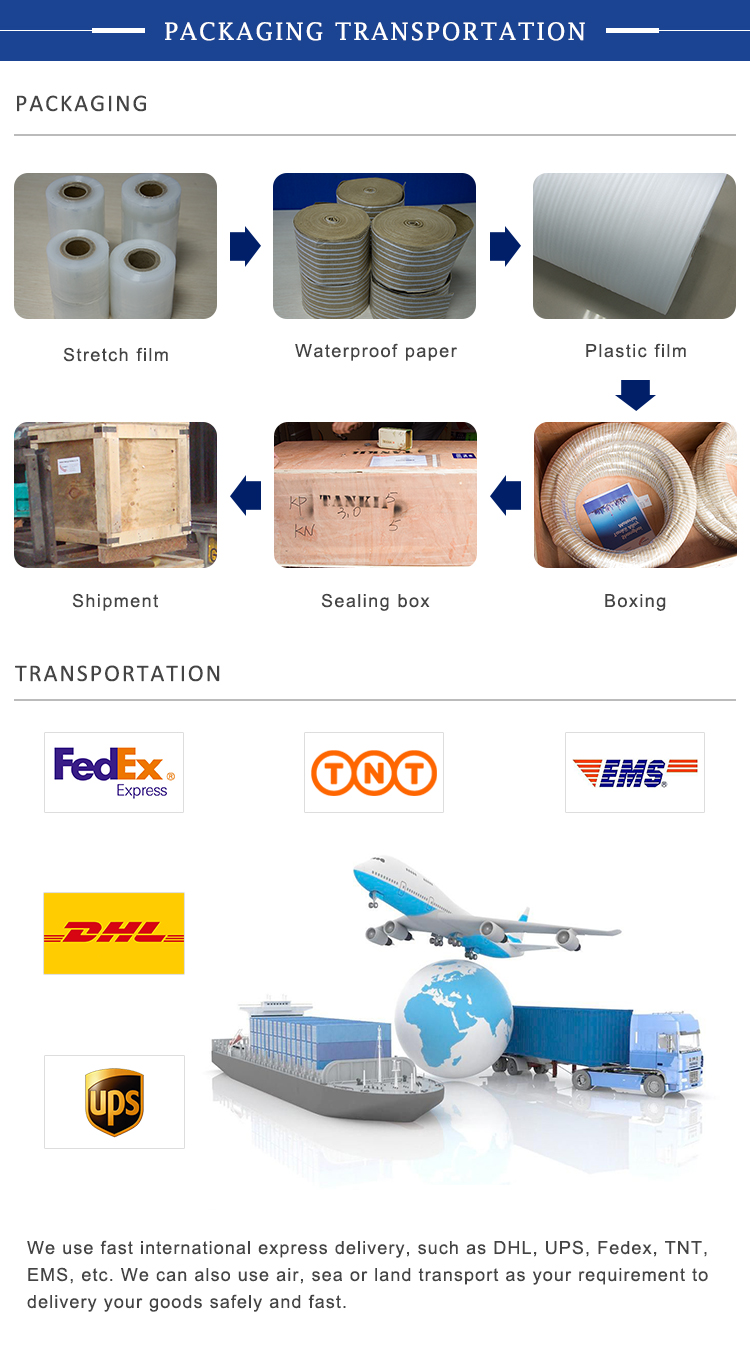

Ntim & Kev Xa Khoom

| Cov Lus Qhia Txog Kev Ntim Khoom: | yas zaj duab xis sab hauv, ntoo pallets sab nraud, xaiv cov ntim khoom tsim nyog, nws tuaj yeem hloov kho los ntawm cov neeg siv khoom xav tau. |

|---|---|

| Kev Qhia Txog Kev Xa Khoom: | txog li 5-25 hnub |

VIM LI CAS THIAJ LI XAIV PEB?

Peb cov khoom siv raw tag nrho yog ua los ntawm cov khoom siv tseem ceeb, tsis yog cov khoom siv rov ua dua tshiab. Peb muaj ntau tshaj 10 xyoo kev paub txog kev tsim cov hlau ua kom sov.

Hauv kev ua lag luam, tsis yog txhua yam NiCr alloys yog nrog cov tshuaj lom neeg tus qauv thiab ruaj khov. Kev tshaj lij thiab txhim khu kev qha yog lub ntsiab lus ntawm peb txoj kev lag luam.

1) Peb ua tiav cov khoom tsim tawm tas li los ntawm kev smelting mus rau cov khoom tiav, peb muaj peev xwm muab cov khoom zoo.

2) Peb muaj lub ntiaj teb qib siab tshaj plaws ntawm German ALD - VIDP1000 - 8000KG lub tshuab nqus tsev induction thiab cov tshuab kos hlau los ntawm Nyiv.

3) Nrog peb cov kev paub txog kev siv lub spooling, peb tau ua tiav qhov hnyav ntawm lub spool. Piv txwv li, txawm tias cov xov hlau zoo heev ntawm 0.04 hli hauv txoj kab uas hla tuaj yeem raug qhwv thiab xa mus rau ntawm 3 - 4 kg bobbin, yog li ntawd tam sim ntawd pab txhawb rau koj txoj kev ua haujlwm zoo.

4) Yuav kom tiv thaiv tau cov xov hlau kom tsis txhob xoob, peb tau tsim cov txheej txheem tswj kev nruj rau hauv peb lub tshuab nqa thiab lub tshuab rov ua dua tshiab.

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj