Txais tos rau peb cov vev xaib!

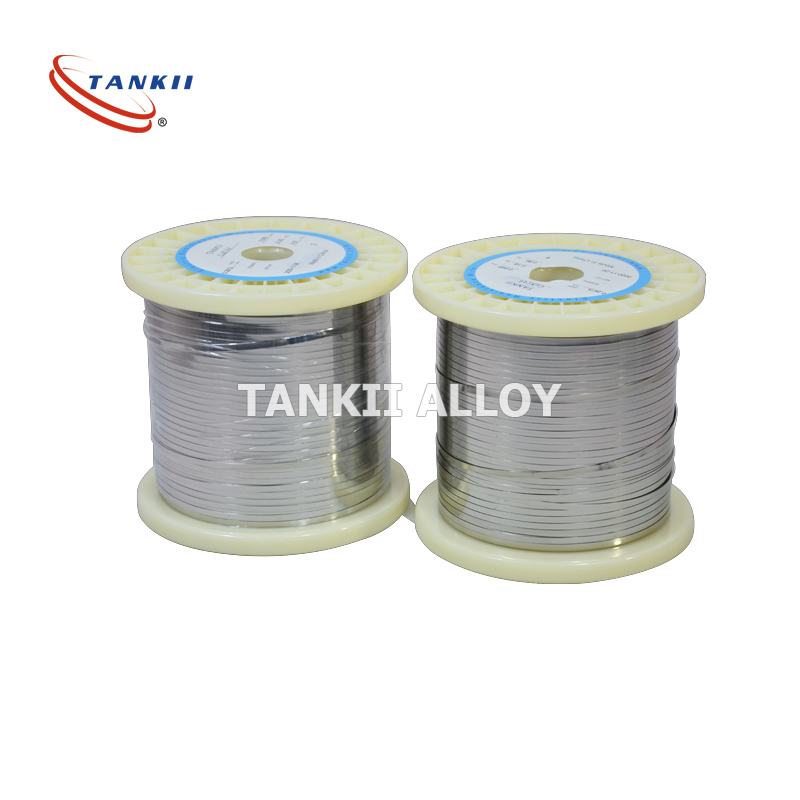

Kev Muab Khoom Siv ASTM TM2 Bimetallic Ribbon, Kev Ruaj Ntseg thiab Kev Ntseeg Siab

Kev piav qhia txog khoom

ASTMTM2bimetallic ribbonHom Lub Npe: Truflex P675R, Chace 7500, Telcon200, Kan 200)

Bimetallic ASTM TM2 tuav cov thermal rhiab heev thiab resistivity siab dua, tab sis modulus ntawm elasticity thiab kev ntxhov siab tso cai qis dua, nws tuaj yeem txhim kho qhov rhiab heev ntawm cov cuab yeej, txo qhov loj me thiab nce lub zog.

Bimetallic ASTM TM2 tuav cov thermal rhiab heev thiab resistivity siab dua, tab sis modulus ntawm elasticity thiab kev ntxhov siab tso cai qis dua, nws tuaj yeem txhim kho qhov rhiab heev ntawm cov cuab yeej, txo qhov loj me thiab nce lub zog.

Kev sau ua ke

| Qib | ASTM TM2 |

| Txheej nthuav dav siab | Mn75Ni15Cu10 |

| Txheej txheem nthuav dav tsawg | Ni36 |

Cov tshuaj lom neeg muaj pes tsawg leeg(%)

| Qib | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Ni36 | ≤0.05 | ≤0.3 | ≤0.6 | ≤0.02 | ≤0.02 | 35~37 | - | - | Bal. |

| Qib | C | Si | Mn | P | S | Ni | Cr | Cu | Fe |

| Mn72Ni10Cu18 | ≤0.05 | ≤0.5 | Bal. | ≤0.02 | ≤0.02 | 9~11 | - | 17~19 | ≤0.8 |

Cov khoom siv lub cev ib txwm muaj

| Qhov Ceev (g/cm3) | 7.7 |

| Kev tiv taus hluav taws xob ntawm 20ºC (ohm mm2 / m) | 1.13 ± 5% |

| Kev ua kom sov, λ / W / (m * ºC) | 6 |

| Modulus Elastic, E/ Gpa | 113~142 |

| Khoov K / 10-6 ºC-1 (20 ~ 135ºC) | 20.8 |

| Kub thiab txias khoov tus nqi F/(20~130ºC)10-6ºC-1 | 39.0% ± 5% |

| Qhov kub uas tso cai (ºC) | -70~ 200 |

| Kub kab ncaj (ºC) | -20~ 150 |

Daim Ntawv Thov:Cov khoom siv feem ntau yog siv ua Cov khoom siv sib khi ua los ntawm cov khoom siv tsis sib xws hauv Gyro thiab lwm yam khoom siv hluav taws xob.

Hom kev muab khoom

| Lub Npe Alloys | Hom | Qhov Loj | ||

| ASTM TM2 | Sawb | W = 5 ~ 120 hli | T = 0.1 hli | |

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj