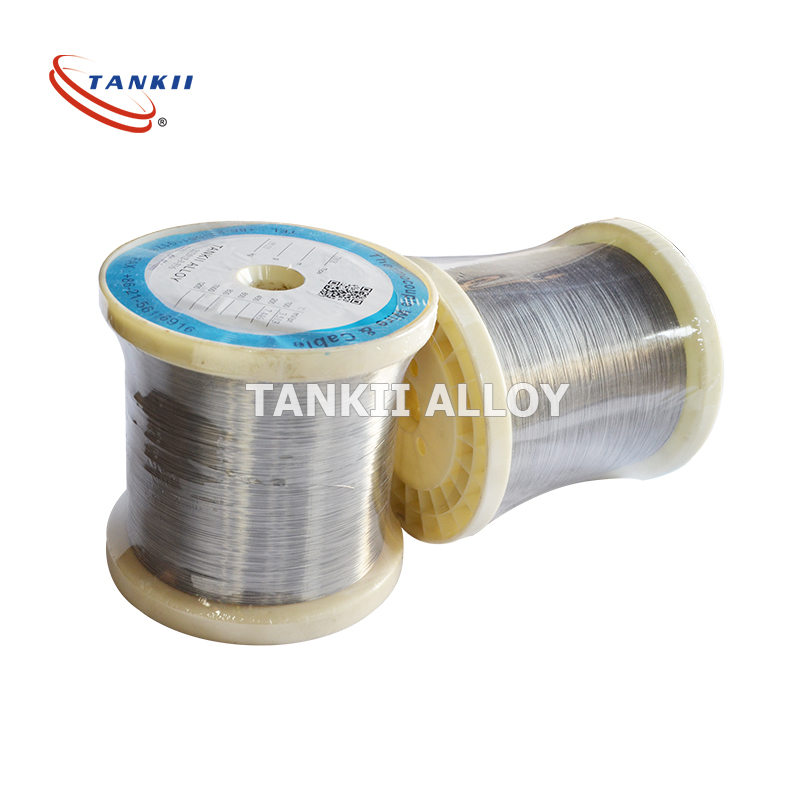

Radiator Kub Tiv Thaiv 0cr25al5 Alloy Hlau Fecral tsis kam hlau

Radiator Resistance Cua Sov Hlau Fecral 0cr25al5 Alloy Hauv Xim Nyiaj Grey

1. Cov Lus Piav Qhia Txog

FeCrAl hlau, 1Cr13Al4,0Cr23Al5, 0Cr25Al5, 0Cr20Al6RE, 0Cr21Al6Nb, 0Cr27Al7Mo2

FeCrAl Alloy yog ib qho ferritic hlau-chromium-aluminium alloy (FeCrAl alloy) rau siv rau hauv arc thiab flame spray systems. Cov alloy no tsim cov txheej txheem ntom ntom, sib txuas zoo, tiv taus kev kub siab oxidation thiab corrosion.

Daim Ntawv Thov lossis Cov Khoom: Cov hlau txau nrog lub zog sib txuas zoo heev. Cov txheej txau ntawm cov khoom no tiv taus qhov sib txawv ntawm qhov kub thiab txias thiab siv ua txheej buffer rau txhua lwm cov hlau txau.

0Cr25Al5

0Cr25Al5 yog ib qho hlau ferritic-chromium-aluminium alloy (FeCrAl alloy) siv rau hauv cov tshuab arc thiab flame spray. Cov alloy no tsim cov txheej txheem ntom ntom, sib txuas zoo, tiv taus kev kub siab oxidation thiab corrosion.

2. Cov Khoom Siv Kho Tshuab

| Max Kev Pabcuam Txuas Ntxiv Mus | 980ºC |

| Kev tiv taus ntawm 20ºC | 1.28 ohm mm2/m |

| Qhov Ceev | 7.4 g/cm3 |

| Kev Ua Kub | 52.7 KJ/m@h@ºC |

| Coefficient ntawm Thermal Expansion | 15.4 × 10-6 / ºC |

| Qhov Kub Yaj | 1450ºC |

| Lub zog tensile | 637~784 Mpa |

| Kev ntev | Yam tsawg kawg nkaus 12% |

| Qhov Kev Hloov Pauv Ntawm Tshooj Ntsws | 65 ~ 75% |

| Rov ua dua zaus khoov | Yam tsawg kawg 5 zaug |

| Lub Sijhawm Pabcuam Txuas Ntxiv Mus | - |

| Qhov nyuaj | 200-260HB |

| Cov Qauv Micrographic | Ferrite |

| Khoom Siv Sib Nqus | Sib nqus |

3. Cov yam ntxwv

Kev ua haujlwm ruaj khov; Tiv thaiv kev oxidation; Tiv thaiv corrosion; Coefficient nthuav dav tsawg; Kev ruaj khov kub siab; Muaj peev xwm ua tau zoo heev; Kev thauj khoom saum npoo av siab; Cov xwm txheej zoo nkauj thiab zoo nkauj yam tsis muaj qhov chaw

4. Cov khoom thiab cov kev pabcuam

1). Dhau: Daim ntawv pov thawj ISO9001, thiab SO14001 daim ntawv pov thawj;

2). Cov kev pab cuam tom qab muag zoo;

3). Kev txiav txim me me raug txais;

4). Cov khoom ruaj khov hauv qhov kub siab;

5). Kev xa khoom sai.

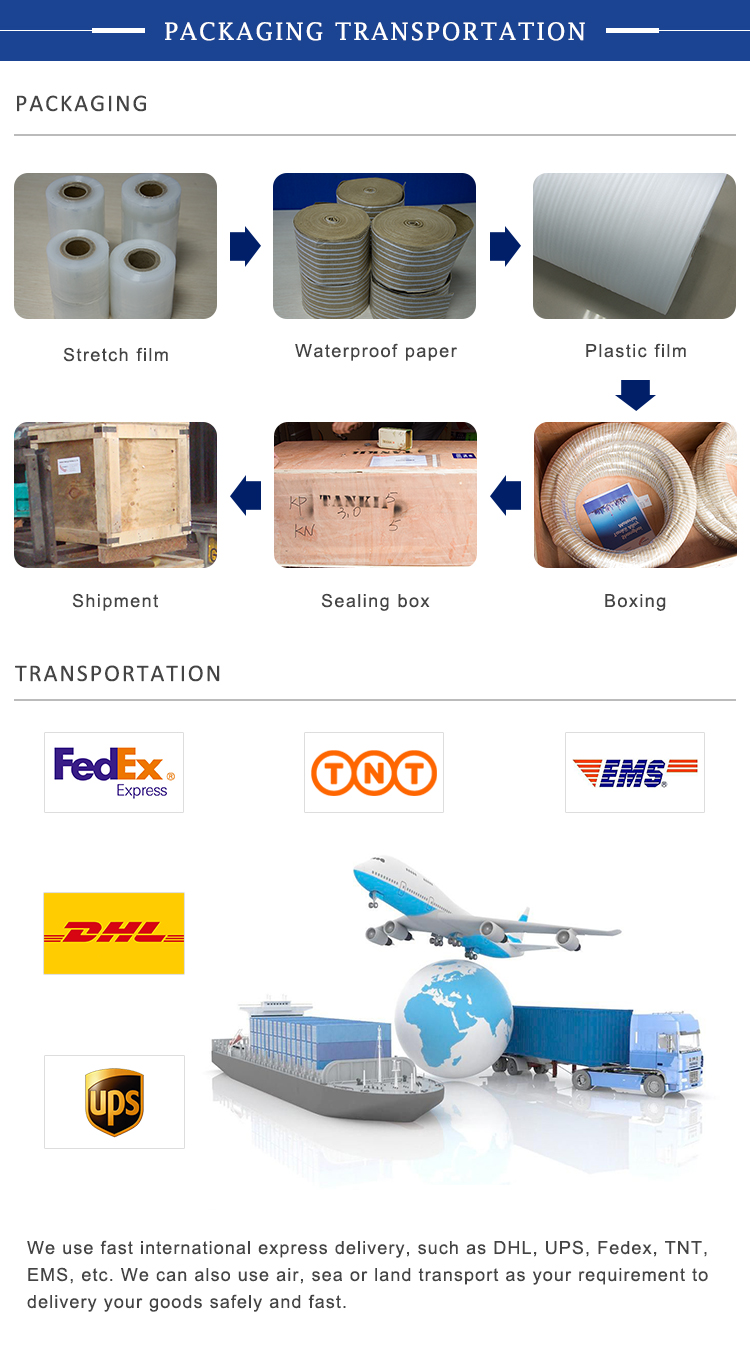

6). Spool, coil, carton, ntoo nrog yas zaj duab xis lossis lwm daim ntawv qhwv raws li tus neeg siv khoom xav tau.

5. Qhov Kub thiab Txias ntawm Hluav Taws Xob Resistivity

| 20ºC | 100ºC | 200ºC | 300ºC | 400ºC | 500ºC | 600ºC | 700ºC | 800ºC | 900ºC | 1000ºC |

| 1 | 1.005 | 1.014 | 1.028 | 1.044 | 1.064 | 1.090 | 1.120 | 1.132 | 1.142 | 1.150 |

6. Cov Tshuaj Lom Zem

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | Lwm yam | ||

| Qhov siab tshaj plaws | |||||||||||

| 0.12 | 0.025 | 0.025 | 0.70 | Siab tshaj 1.0 | 13.0~15.0 | Qhov siab tshaj plaws 0.60 | 4.5~6.0 | Bal. | - | ||

Yog tias koj xav tau, pls tsis yig tiv tauj peb.

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj