Txais tos rau peb cov vev xaib!

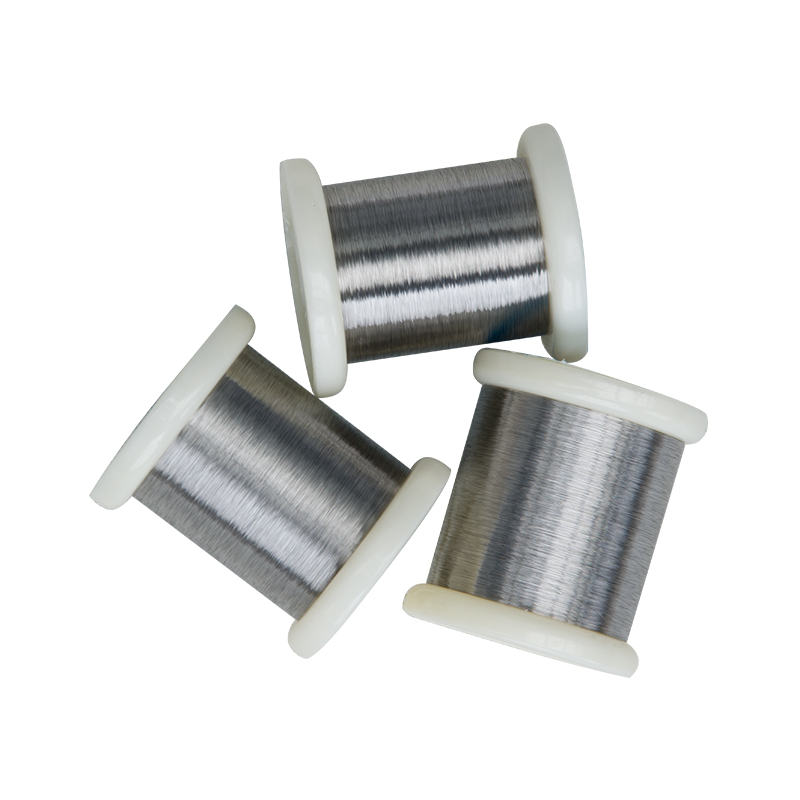

Hlau Tooj Liab AG50cu50 Hlau Tooj Liab

Txoj kab uas hla: 0.1mm-6.0mm Daim ntawv thov: tsim rau brazing hlau, stainless hlau, tooj liab alloys, nickel alloy thiab lwm yam.

Pob: 1Kg/spool; 1Kg/polybag; 2Kg/polybag; Nplhaib, Muab Tshuaj thiab flux coated Muaj; Thawv los yog raws li qhov kev thov.

| Nyiaj Kev Sib Txhuam Hlau | Cov Tshuaj Lom Zem (%) | Solidus | Liquidus | Cov Lus Qhia Tshwj Xeeb (hli) | Cov Qauv |

| BAg10CuZn (HL301) | Ag: 9.0-11.0 Cu: 52.0-54.0 Zn: 35.0-39.0 Lwm yam: Max0.15 | 815ºC | 850ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | Kev Lag Luam |

| BAg15CuZn | Ag: 14.0-16.0 Cu: 46.0-48.0 Zn: 36.0-40.0 Lwm yam: Max0.15 | 750ºC | 830ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | Kev Lag Luam |

| BAg18CuZn | Ag, Cu, Zn | 700ºC | 815ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | Kev Lag Luam |

| BAg20CuZn | Ag: 19.0-21.0 Cu: 43.0-45.0 Zn: 34.0-38.0 Lwm yam: Max0.15 | 690ºC | 810ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | GB/T10046-2008 EN1044:1999 AG206 |

| BAg25CuZn (HL302) | Ag: 24.0-26.0 Cu: 39.0-41.0 Zn: 33.0-37.0 Lwm yam: Max0.15 | 700ºC | 790ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | GB/T10046-2008 EN1044:1999 AG205 ISO 17672: 2010 Ag225 |

| BAg30CuZn | Ag: 29.0-31.0 Cu: 37.0-39.0 Zn: 30.0-34.0 Lwm yam: Max0.15 | 680ºC | 765ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | GB/T10046-2008 AWS A5.8 BAg-20 EN1044:1999 AG204 ISO 17672: 2010 Ag230 |

| BAg35CuZn | Ag: 34.0-36.0 Cu: 31.0-33.0 Zn: 31.0-35.0 Lwm yam: Max0.15 | 685ºC | 775ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | GB/T10046-2008 AWS A5.8 BAg-35 |

| BAg44CuZn | Ag: 43.0-45.0 Cu: 29.0-31.0 Zn: 24.0-28.0 Lwm yam: Max0.15 | 675ºC | 735ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | GB/T10046-2008 EN1044:1999 AG203 ISO 17672: 2010 Ag244 |

| BAg45CuZn (HL303) | Ag: 44.0-46.0 Cu: 29.0-31.0 Zn: 24.0-27.0 Lwm yam: Max0.15 | 665ºC | 745ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | GB/T10046-2008 AWS A5.8 BAg-5 |

| BAg50CuZn (HL304) | Ag: 49.0-51.0 Cu: 33.0-35.0 Zn: 14.0-18.0 Lwm yam: Max0.15 | 690ºC | 775ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | GB/T10046-2008 AWS A5.8 BAg-6 |

| BAg60CuZn | Ag: 59.0-61.0 Cu: 25.0-27.0 Zn: 12.0-16.0 Lwm yam: Max0.15 | 695ºC | 730ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | GB/T10046-2008 EN1044:1999 AG202 |

| BAg65CuZn (HL306) | Ag: 64.0-66.0 Cu: 19.0-21.0 Zn: 13.0-17.0 Lwm yam: Max0.15 | 670ºC | 720ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | GB/T10046-2008 AWS A5.8 BAg-9 |

| BAg70CuZn (HL307) | Ag: 6.0-7.0 Cu: 19.0-21.0 Zn: 8.0-12.0 Lwm yam: Max0.15 | 690ºC | 740ºC | Qws/Hlau/Nplhaib/Tiaj ≥φ0.2 Sawb/Siv/Ntawv ci /ua ntej Thickness≥0.05 2.0≤Width≤100 | GB/T10046-2008 AWS A5.8 BAg-10 |

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj