Txais tos rau peb cov vev xaib!

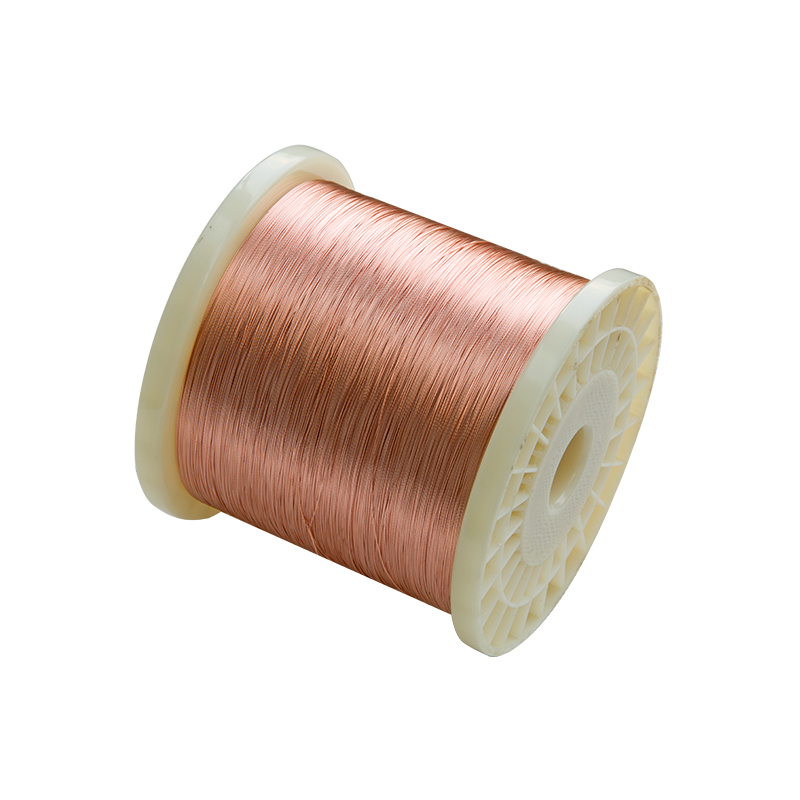

Tankii 1.0mm Tinned Copper Wire T2 Liab Copper Anti-Oxidation & Zoo heev Conductivity

Kev piav qhia txog khoom

1.0 hli Tinned Tooj Liab Hlau (Pure Liab Tooj Liab Core, 3-5μ Tin Txheej)

Txheej Txheem Cej Luam Khoom

Ua tus neeg hluav taws xob muaj kev ntseeg siab los ntawm Tankii Alloy Material, tus1.0 hli tinned tooj liab hlaumuaj ob qho txiaj ntsig tseem ceeb: qhov ua tau zoo heev ntawm cov tooj liab liab ntshiab (T2 qib) thiab kev tiv thaiv xeb ntawm cov txheej txheem tin 3-5μ. Tsim los ntawm Huona txoj kev ua kom kub-dip tinning txuas ntxiv mus - nruab nrog kev saib xyuas tuab tiag tiag thiab kev tswj kub - cov hlau ua kom cov txheej tin lo rau 1.0 hli cov hlau tooj liab khov kho, tsis muaj qhov lossis cov qhov nyias nyias. Nws daws ob qho teeb meem tseem ceeb ntawm cov hlau tooj liab liab qab: oxidation-induced conductivity poob qis thiab tsis zoo solderability, ua rau nws yog ib qho tseem ceeb rau kev sib txuas hluav taws xob uas xav tau kev ruaj khov ntev, yooj yim sib dhos, thiab tiv taus cov av noo / chaw ua lag luam.

Cov Ntawv Pov Thawj Txheem & Cov Khoom Siv

- Qib Tus Neeg CojT2 tooj liab ntshiab (ua raws li GB/T 3956-2008; sib npaug rau ASTM B33, IEC 60288 Chav Kawm 1)

- Txheej Txheem TinGB/T 4910-2009, IEC 60317-2 (tsis muaj txhuas: Pb ≤0.005%, Sn ≥99.9%)

- Cov Ntawv Pov Thawj ZooUa raws li RoHS 2.0, ISO 9001 kev tswj hwm zoo, SGS kev pom zoo rau kev kuaj ib puag ncig

- Chaw Tsim Khoom: Tankii Alloy Khoom Siv (15+ xyoo ntawm kev paub txog kev ua cov tooj liab hlau)

Cov txiaj ntsig ntawm kev ua tau zoo tseem ceeb

1. Tus Neeg Hlau Liab Ntshiab: Kev Ua Hluav Taws Xob Tsis Sib Xws

- Kev Ua Hluav Taws Xob: ≥98% IACS (20 ℃), ntau tshaj li cov tooj liab uas muaj hlau sib xyaw (piv txwv li, CuNi alloys: ~20% IACS) thiab txhuas (61% IACS). Xyuas kom muaj qhov hluav taws xob tsawg kawg nkaus hauv cov voj voog hluav taws xob qis (piv txwv li, 12V tsheb hluav taws xob, 5V USB cables) thiab xa cov teeb liab sai rau cov sensors.

- Kev Ua Haujlwm Mechanical Ductility: Kev ntev ≥30% (25℃) thiab lub zog tensile ≥200 MPa. Muaj peev xwm tiv taus kev khoov rov qab (kev sim khoov 180° ≥10 zaug yam tsis tawg) rau kev txuas hluav taws xob hauv qhov chaw nqaim (piv txwv li, cov chaw sab hauv ntawm cov khoom siv, kev sib txuas ntug PCB).

2. 3-5μ Precision Tin Txheej: Kev Tiv Thaiv Lub Hom Phiaj

- Kev Tiv Thaiv OxidationCov txheej tin tuab tuab thaiv cua/dej kom tsis txhob kov tooj liab, tiv thaiv kev tsim cov tooj liab oxide (CuO/Cu₂O). Txawm tias nyob hauv 80% av noo rau 12 lub hlis, cov hlau tseem tswj tau ≥97% kev coj hluav taws xob pib (piv rau tooj liab liab qab: poob rau 85% hauv 3 lub hlis).

- Kev txhim kho kev sib txuas lus zoo dua: Lub tin lub melting point qis (232 ℃) ua rau "instant wetting" thaum lub sijhawm soldering - tsis tas yuav tsum tau ntxuav ua ntej lossis ua kom muaj flux. Txo lub sijhawm sib dhos PCB los ntawm 40% piv rau tooj liab liab (uas xav tau kev tshem tawm oxide los ntawm kev xuab zeb / tshuaj lom neeg).

- Tsim Kev Sib Npaug Thickness: 3-5μ tuab zam ob qhov kawg: cov txheej nyias nyias (<3μ) tsis tuaj yeem npog cov qhov tsis zoo ntawm tooj liab, thaum cov txheej tuab dua (>5μ) ua rau cov hlau tawg (feem ntau tawg thaum khoov).

Cov Lus Qhia Txog Kev Siv

| Cov Qauv | Tus nqi ntxaws ntxaws |

| Nominal Txoj Kab uas hla (Zuag qhia tag nrho) | 1.0 hli (tus neeg coj: ~ 0.992-0.994 hli; txheej tin: 3-5μ) |

| Kev kam rau txoj kab uas hla | ±0.02 hli |

| Tin Txheej Thickness | 3μ (yam tsawg kawg nkaus) - 5μ (siab tshaj plaws); qhov tuab sib xws: ≥95% (tsis muaj qhov chaw <2.5μ) |

| Kev Ua Hluav Taws Xob (20 ℃) | ≥98% IACS |

| Lub zog tensile | 200-250 MPa |

| Kev ntev thaum tawg | ≥30% (L0 = 200 hli) |

| Tin Adhesion | Tsis muaj tev tawv/plhaub tom qab khoov 180° (radius = 5mm) + sim daim kab xev (3M 610 daim kab xev, tsis muaj tin residue) |

| Kev Tiv Thaiv Kev Xeb | Dhau ASTM B117 kev sim tshuaj tsuag ntsev (48 teev, 5% NaCl, 35 ℃) - tsis muaj xeb liab, tin blistering |

| Kev Ua Haujlwm Kub Ntau | -40 ℃ (qhov kub qis, tsis tawg) txog 105 ℃ (siv tas mus li, tsis yaj tin) |

Kev Muab Khoom & Kev Kho Kom Haum

| Khoom | Cov Lus Qhia Tshwj Xeeb |

| Daim Ntawv Muab Khoom | Tus neeg hlau khov kho (tus qauv); tus neeg hlau khi (kev cai: 7 / 0.43mm, 19 / 0.26mm) |

| Kev Teeb tsa Spool | 500m/1000m ib lub spool (cov khoom siv spool: ABS yas, txoj kab uas hla: 200mm, qhov tseem ceeb: 50mm) |

| Qhov Chaw Tiav | Xim ci ntsa iab (ua ntej); xim matte (kev cai, rau cov ntawv thov tiv thaiv kev ci ntsa iab) |

| Kev Kho Mob Ntxiv | Kev rwb thaiv tsev xaiv tau (PVC/XLPE/Silicone, tuab: 0.1-0.3 hli, xim: dub/liab/xiav) |

| Ntim Khoom | Lub hnab ntawv ci txhuas uas kaw nrog lub tshuab nqus tsev (tsis ntub dej) + lub thawv sab nraud (nrog cov tshuaj desiccant, tiv thaiv kev cuam tshuam) |

Cov Xwm Txheej Ib Txwm Muaj Rau Daim Ntawv Thov

- Cov Khoom Siv Hauv TsevCov xov hlau sab hauv rau cov tshuab ntxhua khaub ncaws (tsis pub dej noo nkag), cov tub yees (yooj yim rau qhov kub qis), thiab cov qhov cub microwave (tsis pub cua sov txog li 105 ℃).

- Tsheb Khoom Siv Hluav Taws XobCov qhov txuas rau cov roj teeb tsheb (tiv thaiv kev xeb), cov xov hluav taws xob sensor (lub teeb liab ruaj khov), thiab cov kab ke infotainment hauv tsheb (qhov hluav taws xob poob qis).

- PCB & Cov Khoom Siv Hluav Taws Xob Rau Cov Neeg Siv KhoomKev sib txuas ntawm qhov rau Arduino/Raspberry Pi boards, USB-C cable conductors, thiab LED strip wiring (yooj yim sib dhos).

- Kev Tswj Xyuas Kev Lag LuamKev sib txuas hluav taws xob rau PLC panels (kev tiv taus cov av noo hauv kev lag luam) thiab cov khoom siv hluav taws xob qis (kev poob hluav taws xob tsawg kawg nkaus).

- Cov Khoom Siv Kho Mob: Cov xov hlau sab hauv rau cov cuab yeej kuaj mob uas nqa tau yooj yim (tsis muaj txhuas, ua raws li cov qauv biocompatibility) thiab cov twj tso kua mis me me (khoov tau yooj ywm).

Kev Ruaj Ntseg Zoo los ntawm Tankii Alloy Khoom Siv

Txhua pawg ntawm 1.0 hli tinned tooj liab hlau raug kuaj xyuas peb qhov tseem ceeb:

- Kev Ntsuas Qhov Thickness ntawm Tin: X-ray fluorescence (XRF) analyzer (precision: ±0.1μ) - 5 cov ntsiab lus kuaj ib lub spool.

- Kev Ntsuas Kev Ua Hluav Taws Xob: Plaub lub qhov ntsuas qhov ntsuas (qhov tseeb: ± 0.5% IACS) - 3 cov qauv ib pawg.

- Kev Ntsuas TshuabLub tshuab kuaj thoob ntiaj teb (tensile/elongation) + lub tshuab kuaj khoov (adhesion) - 2 daim qauv rau ib pawg.

Cov qauv pub dawb (ntev 1m, 2-3 daim rau ib qho kev qhia tshwj xeeb) thiab cov ntaub ntawv qhia txog kev sim khoom siv (MTR) muaj thaum thov. Peb pab neeg ua haujlwm muab kev pabcuam ib leeg rau ib leeg rau cov kev xav tau tshwj xeeb (piv txwv li, kev xaiv cov khoom siv rwb thaiv tsev rau cov ntawv thov kub siab, kev tsim cov xov hlau txuas rau cov xov hlau hloov tau yooj yim).

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj