Txais tos rau peb cov vev xaib!

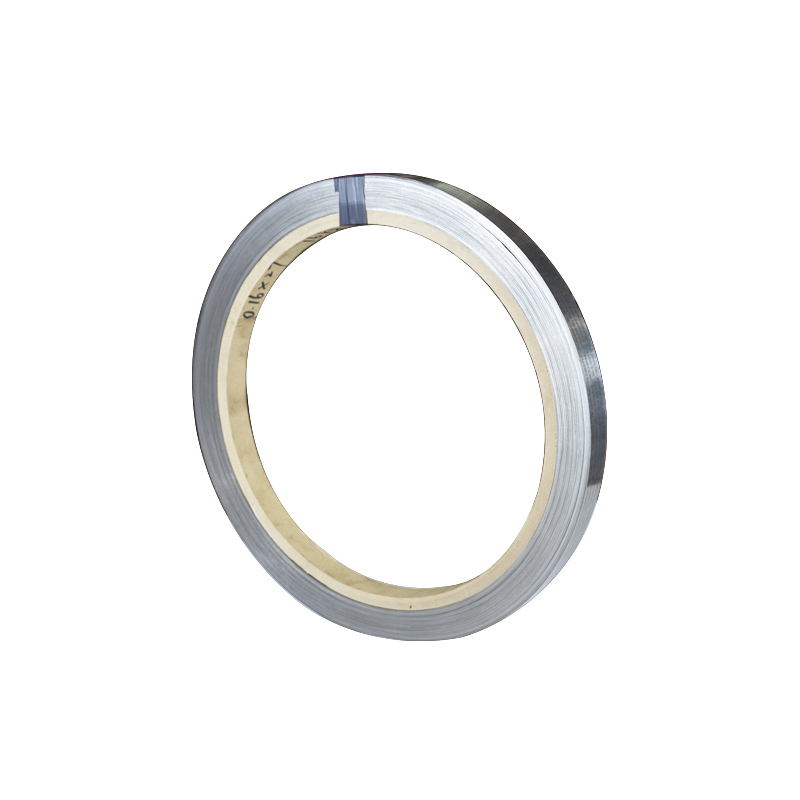

Tankii Kub Muag TM-1/FPA223-80/5J1480 Bimetallic Sawb 0.1mm Thickness × 100mm Dav

Kev piav qhia txog khoom

TM-1 Bimetallic Sawb (0.1mm Thickness × 100mm Dav)

Txheej Txheem Cej Luam Khoom

TM-1bimetallic strips(0.1mm × 100mm), ib yam khoom siv ua haujlwm precision-engineered los ntawm Tankii Alloy Material, yog ib daim kab xev nyias nyias uas muaj ob hom hlau sib txawv nrog cov coefficients thermal expansion sib txawv - sib txuas los ntawm peb cov thev naus laus zis kub-rolling diffusion. Optimized rau cov ntawv thov ultra-thin uas xav tau ob qho tib si miniaturization thiab txhim khu kev qha thermal actuation, daim kab xev no ua ke ib qho 0.1mm tuab (zoo tagnrho rau cov khoom siv compact) nrog 100mm qhov dav tus qauv (haum rau thaj chaw loj kub sensing lossis batch processing). Siv Huona txoj kev txawj ntse hauv kev tsim khoom sib xyaw nyias-gauge, qib TM-1 muab kev rhiab heev thermal, kev hloov pauv sib xws, thiab kev sib txuas interfacial muaj zog - ua rau nws yog ib qho khoom tseem ceeb rau micro-thermostats, precision temperature compensators, thiab miniaturized overheat protection devices.

Cov Qauv Txheem & Cov Qauv Tseem Ceeb

- Qib Khoom: TM-1 (qib bimetallic tshwj xeeb, tsim rau ultra-thin gauge thermal responsiveness)

- Kev Ntsuas Qhov Ntev: 0.1 hli tuab (kev kam rau siab: ± 0.003 hli) × 100 hli dav (kev kam rau siab: ± 0.15 hli)

- Cov Qauv Sib Xyaws: Feem ntau muaj cov txheej txheem nthuav dav (piv txwv li, Cu-Mn-Zn alloy, α≈20 × 10⁻⁶ / ℃) thiab cov txheej txheem nthuav dav qis (piv txwv li, Fe-Ni 36 alloy, α≈1.6 × 10⁻⁶ / ℃), nrog rau lub zog interfacial shear ≥145 MPa (sim ib GB / T 14985)

- Cov Qauv Ua Raws Cai: Ua raws li GB / T 14985-2017 (Tus qauv Suav raubimetallic stripss) thiab IEC 60694 rau cov khoom tswj cua sov

- Chaw Tsim Khoom: Tankii Alloy Khoom Siv, tau ntawv pov thawj rau ISO 9001 thiab ISO 14001, nrog rau kev dov nyias-gauge thiab kev txiav qhov tseeb.

Cov Kev Zoo Tseem Ceeb (piv rau Cov Hlau Bimetallic Txheem & Cov Hlau Thick-Gauge)

Lub TM-1 strip (0.1mm × 100mm) sawv tawm rau nws txoj kev tsim ultra-thin thiab qhov dav dav:

- Ultra-Thin Precision: 0.1 hli tuab (30% nyias dua li cov kab txaij 0.15 hli ib txwm muaj) ua rau muaj kev sib koom ua ke rau hauv cov khoom siv me me (piv txwv li, cov sensors hnav tau, cov khoom siv hluav taws xob me me) thaum tswj hwm qhov tuab sib xws (± 0.003 hli) kom tsis txhob muaj kev hloov pauv thermal tsis sib xws.

- Kev Ruaj Ntseg Thermal Zoo Dua: Qhov sib piv ntawm cov coefficient nthuav dav siab (~ 12.5: 1) ua rau muaj qhov nkhaus ntawm 12-15 m⁻¹ (ntawm 100 ℃ vs. 25 ℃) - siab dua 20% dua li cov kab tuab (0.3 hli +), ua kom muaj kev ua haujlwm sai hauv cov khoom siv hluav taws xob tsawg.

- Dav Dav Rau Kev Ua Haujlwm Ua Ib Pawg: 100 hli qhov dav tus qauv phim cov qhov loj ntawm vaj huam sib luag stamping hauv kev lag luam, tso cai rau kev tsim khoom ntawm 50+ cov khoom me me (piv txwv li, cov khoom sib cuag thermostat) ib daim kab xev - txo lub sijhawm ua tiav los ntawm 40% piv rau cov kab xev dav.

- Kev Sib Txuas Lus Muaj Zog: Cov thev naus laus zis sib txuas lus tshwj xeeb tshem tawm qhov delamination txawm tias tom qab 8,000 lub voj voog thermal (-40 ℃ txog 180 ℃) - daws qhov teeb meem feem ntau ntawm cov bimetallics nyias-gauge (≤0.1mm) uas yooj yim rau kev sib cais txheej.

- Kev Siv Tau Zoo Kawg Nkaus: Lub ntsuas nyias nyias ua rau laser txiav rau hauv cov duab me me (qhov tsawg kawg nkaus: 0.5 hli) thiab khoov nruj (radius ≥1 × tuab) yam tsis muaj kev tawg - qhov tseem ceeb rau kev sib dhos ua ke ntawm cov khoom siv me me.

Cov Lus Qhia Txog Kev Siv

| Tus cwj pwm | Tus nqi (Ib txwm muaj) |

|---|---|

| Qhov tuab | 0.1 hli (kev kam rau siab: ± 0.003 hli) |

| Dav | 100 hli (kev kam rau siab: ± 0.15 hli) |

| Ntev ib yob | 50m - 200m (txiav-rau-ntev muaj: ≥50mm) |

| Qhov Sib Piv ntawm Cov Coefficient Expansion Thermal (Txheej Siab/Qis) | ~12.5:1 |

| Kev Ua Haujlwm Kub Ntau | -40 ℃ txog 180 ℃ (txuas ntxiv); Lub sijhawm luv luv: txog li 220 ℃ (≤ 30 feeb) |

| Kev Hloov Pauv Kub ntawm Kev Ua Haujlwm | ±2℃ (ntawm cov ntsiab lus ntsuas: 50℃ - 150℃) |

| Lub zog ntawm kev sib txuas ntawm lub cev | ≥145 MPa |

| Lub Zog Tensile (Transverse) | ≥470 MPa |

| Kev ntev (25 ℃) | ≥10% |

| Kev tiv taus (25 ℃) | 0.17 – 0.30 Ω·mm²/m |

| Qhov Roughness ntawm qhov chaw (Ra) | ≤0.6μm (zeb tiav) |

Cov Lus Qhia Txog Khoom

| Khoom | Cov Lus Qhia Tshwj Xeeb |

|---|---|

| Qhov Chaw Tiav | Xim tiav (tsis muaj oxide) lossis passivated (xaiv tau, rau 72-teev ntsev tsuag tsis kam) |

| Kev tiaj tiaj | ≤0.06mm/m (tseem ceeb rau kev sib dhos thiab kev hloov pauv thermal) |

| Kev Sib Txuas Zoo | 100% kev sib txuas ntawm cov ntaub so ntswg (tsis muaj qhov khoob > 0.03mm², tau txheeb xyuas los ntawm kev tshuaj xyuas X-ray) |

| Kev ua tau zoo ntawm kev vuam | Xaiv tau tin-plating (2-3μ tuab) rau kev txhim kho solderability hauv micro-connections |

| Ntim Khoom | Ntim nrog lub tshuab nqus tsev kaw rau hauv cov hnab tiv thaiv kev oxidation nrog cov desiccants; cov yas spools (120mm txoj kab uas hla) kom tiv thaiv cov strip warping |

| Kev Kho Kom Haum | Kev kho qhov kub thiab txias ntawm qhov kev ua haujlwm (40 ℃ - 180 ℃), kev txiav dav (yam tsawg kawg nkaus 10 hli), thiab cov qauv me me uas tau muab luam tawm ua ntej |

Cov Ntawv Thov Ib Txwm Muaj

- Micro-Thermostats: Kev tswj qhov kub thiab txias hauv cov khoom siv hnav tau (piv txwv li, cov moos ntse), cov tshuaj insulin txias rau kev kho mob, thiab cov kab ke HVAC me me (0.1 hli tuab haum rau cov qauv tsim nyias).

- Kev Tiv Thaiv Kub Dhau: Cov cuab yeej hluav taws xob rau cov roj teeb lithium-ion (piv txwv li, roj teeb drone, pob ntseg wireless) thiab cov micro-motors (kev ua haujlwm sai tiv thaiv kev khiav tawm ntawm thermal).

- Kev Tshawb Fawb Thaj Chaw Loj: Cov ntawv thermal profiling rau PCB boards (dav 100mm npog ntau yam khoom) thiab cov khoom siv hluav taws xob yooj ywm (qhov kub teb sib npaug thoob plaws daim ntawv).

- Cov Khoom Siv Hluav Taws Xob Rau Cov Neeg Siv Khoom: Cov cuab yeej ua kom sov rau lub laptop, cov cuab yeej tswj lub tshuab luam ntawv, thiab cov khoom siv tiv thaiv roj teeb ntawm lub xov tooj ntse.

- Cov Khoom Siv Me Me Hauv Kev Lag Luam: Cov shims uas them qhov kub thiab txias rau MEMS sensors (piv txwv li, cov sensors siab hauv cov tsheb tsis muaj neeg tsav) thiab cov hloov pauv cua sov me me rau cov khoom siv IoT.

Cov Khoom Siv Tankii Alloy raug kuaj xyuas txhua pawg ntawm TM-1 strips (0.1mm × 100mm) kom nruj: kev txheeb xyuas lub zog interfacial shear, 1000-cycle thermal stability tests, thiab laser-based dimensional inspection. Cov qauv dawb (100mm × 50mm) thiab thermal curvature vs. temperature curves muaj thaum thov. Peb pab neeg muab kev txhawb nqa tshwj xeeb - suav nrog kev ua kom zoo dua ntawm cov txheej txheem alloy rau cov kub tshwj xeeb thiab cov txheej txheem micro-stamping - kom ntseeg tau tias cov strips ua tau raws li qhov xav tau ntawm cov ntawv thov compact, high-precision.

Sau koj cov lus ntawm no thiab xa tuaj rau peb

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj