Alkrothal 720 No.1 JR FeCrAl Alloy rau lub nres resistor

Alkrothal 720 No. 1 JRrau lub nres resistor

Cov ntawv thov feem ntau rau Alkrothal 720 yog nyob rau hauv rheostats, braking resistors, thiab lwm yam. Nws kuj tseem siv ua cov khoom siv hluav taws xob cua sov hauv kev siv hauv kev lag luam.

Alkrothal 720 yog ferritic hlau-chromium-aluminium alloy (FeCrAl alloy) rau kev siv ntawm qhov kub txog li 1000 ° C (1830 ° F).

Kev Tshuaj Xyuas Nominal

| Cr | Al | Fe |

| 12.0~15.0 | 4.0~6.0 | Qhov Nyiaj Tshuav |

Cov Khoom Siv Kho Tshuab

| Kub Tshaj Plaws Kev Pabcuam Txuas Ntxiv Mus: Kev tiv taus 20ºC: Qhov Ceev: Kev Ua Kub: Coefficient ntawm Thermal Expansion: Melting Point: Kev ntev: Cov Qauv Micrographic: Khoom Siv Sib Nqus: | 950ºC 1.25ohm mm2/m 7.40g/cm3 52.7 KJ/m·h·ºC 15.4 × 10-6 / ºC (20ºC ~ 1000ºC) 1450ºC Yam tsawg kawg nkaus 16% Ferrite sib nqus |

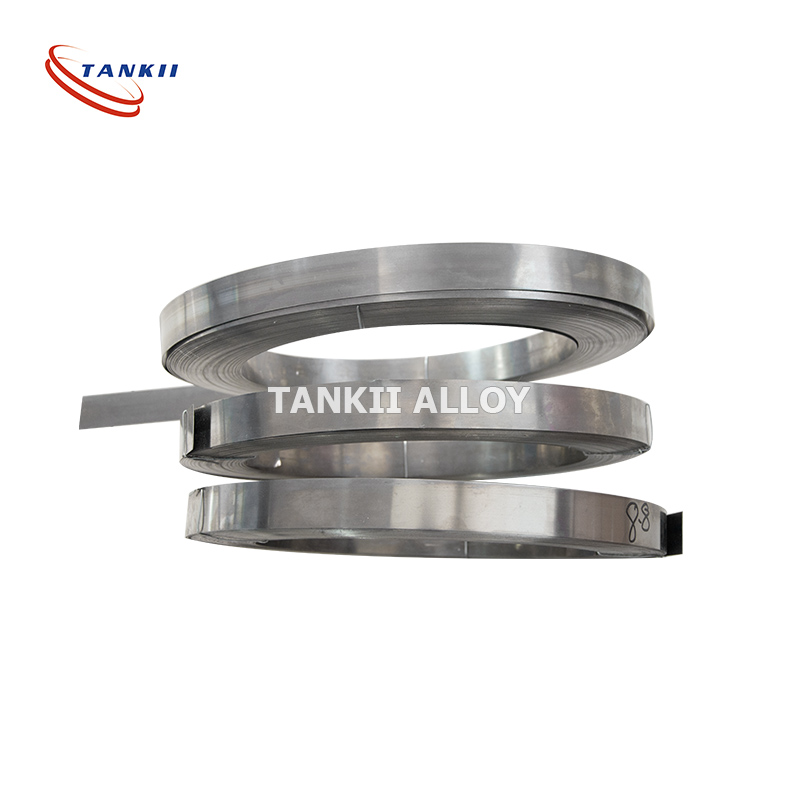

Loj: Thickness 0.01-7mm, dav 0.5-1000mm

Nto: BA, 2B

Hardness: Mos, Ib Nrab Nyuaj, Nyuaj

Tau siv dav dav ua lub zog loj nres resisor thiab lub cub tawg cua sov.

Muaj lub zog kub tsawg dua li Tophet alloys tab sis qhov kub siab dua.

Shanghai TANKII ALLOY khoom Co., Ltd.

FECRAL THIAB ALCHROME ALLOY PRODUCER HAUV Suav teb, FEEM NTAU PROFESSIONAL HAUV NTIJ TEB

Peb kuj tsim cov qib hauv qab no:

0Cr15Al5 thiab 0Cr19Al3, thiab lwm yam.

| Cov Tshuaj Lom Zem thiab Cov Khoom Tseem Ceeb ntawm Fe-Cr-Al Resistance Alloy | ||||||||

| Qib Khoom | 1Cr13Al4 | 0Cr25Al5 | 0Cr21Al6 | 0Cr23Al5 | 0Cr21Al4 | 0Cr21Al6Nb | 0Cr27Al7Mo2 | |

| Cov Tshuaj Lom Zem Tseem Ceeb (%) | Cr | 12.0-15.0 | 23.0-26.0 | 19.0-22.0 | 22.5-24.5 | 18.0-21.0 | 21.0-23.0 | 26.5-27.8 |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 | 6.0-7.0 | |

| Re | lub sijhawm zoo | lub sijhawm zoo | lub sijhawm zoo | lub sijhawm zoo | lub sijhawm zoo | lub sijhawm zoo | lub sijhawm zoo | |

| Fe | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | |

| Nb0.5 | Mo1.8-2.2 | |||||||

| Qhov Kub Tshaj Plaws Kev Pabcuam Txuas Ntxiv Mus (oC) | 950 | 1250 | 1250 | 1250 | 1100 | 1350 xyoo | 1400 | |

| Kev Tiv Thaiv 20oC (Ωmm2 / m) | 1.25 ±0.08 | 1.42 ±0.06 | 1.42 ±0.07 | 1.35 ±0.07 | 1.23 ±0.07 | 1.45 ±0.07 | 1.53 ±0.07 | |

| Qhov Ceev (g/cm3) | 7.4 | 7.1 | 7.16 | 7.25 | 7.35 | 7.1 | 7.1 | |

| Kev Ua Kub | 52.7 | 46.1 | 63.2 | 60.2 | 46.9 | 46.1 | 45.2 | |

| (KJ/m@h@oC) | ||||||||

| Coefficient ntawm Thermal Expansion (α × 10-6 / oC) | 15.4 | 16 | 14.7 | 15 | 13.5 | 16 | 16 | |

| Kwv yees li ntawm Melting Point (oC) | 1450 xyoo | 1500 xyoo | 1500 xyoo | 1500 xyoo | 1500 xyoo | 1510 | 1520 xyoo | |

| Lub zog tensile (N / mm2) | 580-680 | 630-780 | 630-780 | 630-780 | 600-700 | 650-800 | 680-830 | |

| Kev ntev (%) | >16 | >12 | >12 | >12 | >12 | >12 | >10 | |

| Kev Hloov Pauv ntawm Tshooj | 65-75 | 60-75 | 65-75 | 65-75 | 65-75 | 65-75 | 65-75 | |

| Tus Nqi Ntsws (%) | ||||||||

| Rov ua dua zaus khoov (F / R) | >5 | >5 | >5 | >5 | >5 | >5 | >5 | |

| Qhov nyuaj (HB) | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | 200-260 | |

| Lub Sijhawm Pabcuam Txuas Ntxiv Mus | no | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Cov Qauv Micrographic | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Khoom Siv Sib Nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | |

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj