Alkrothal 720 No.1 JR FeCrAl Alloy rau nres resistor

Alkrothal 720 Nr 1 JRrau brake resistor

Cov ntawv thov rau Alkrothal 720 yog nyob rau hauv rheostats, braking resistors, thiab lwm yam. Nws kuj yog siv los ua hluav taws xob cua sov cov ntsiab lus hauv cov ntawv thov kev lag luam.

Alkrothal 720 yog ferritic hlau-chromium-aluminium alloy (FeCrAl alloy) siv rau qhov kub txog li 1000 ° C (1830 ° F).

Nominal Analysis

| Cr | Al | Fe |

| 12.0-15.0 Nws | 4.0 ~ 6.0 | Tshuav |

Mechanical Properties

| Max Continuous Service Temperature: Kev kub siab 20ºC: Ceev: Thermal conductivity: Coefficient ntawm Thermal Expansion: Melting Point: Elongation: Micrographic Structure: Magnetic Property: | 950ºC ua 1.25 ohm mm2 / m 7.40 g / cm3 52.7 KJ/m·h·°C 15.4 × 10-6 / ºC (20ºC ~ 1000ºC) 1450ºC Tsawg tshaj 16% Ferrite Sib nqus |

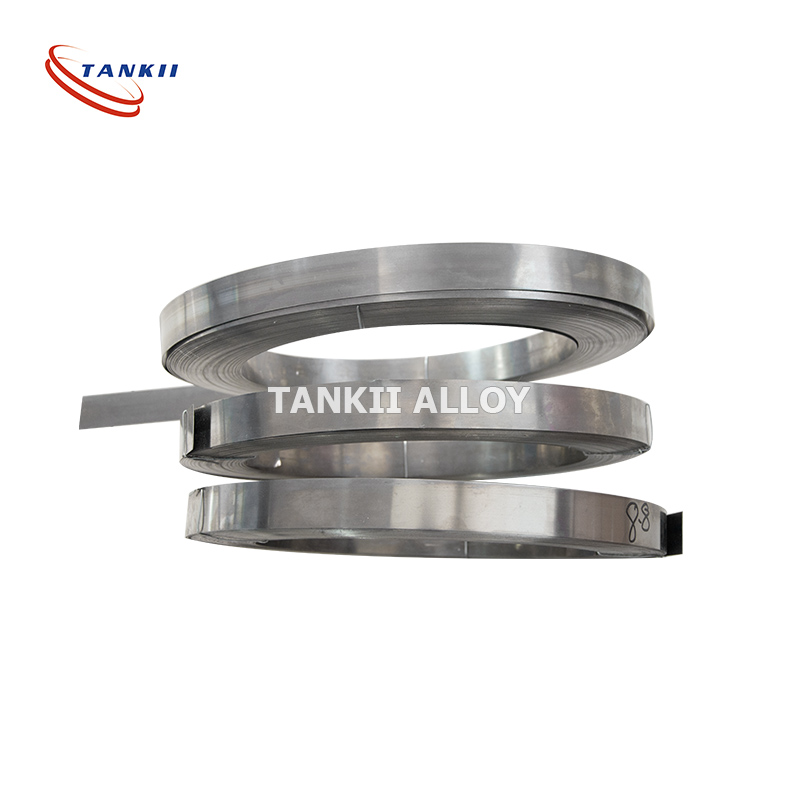

Loj: Thickness 0.01-7mm, dav 0.5-1000mm

Nto: BA, 2B

Hardness: Mos, Ib nrab nyuaj, nyuaj

Nws tau siv dav raws li lub zog loj nres resisor thiab cov cua kub cua sov.

Muaj zog kub tsawg dua Tophet alloys tab sis ntau dua melting point.

Shanghai TANKII ALLOY khoom Co., Ltd.

FECRAL THIAB ALCHROME ALLOY PRODUCER nyob rau hauv Suav teb, feem ntau tshaj lij nyob rau hauv lub ntiaj teb no

Peb kuj tsim cov qib hauv qab no:

0Cr15Al5 thiab 0Cr19Al3, thiab lwm yam.

| Chemical Composition thiab Main Property ntawm Fe-Cr-Al Resistance Alloy | ||||||||

| Qib Qib | 1Cr13Al4 | 0c25l 5 | 0c21 ua 6 | 0c23l 5 | 0c21 ua 4 | 0Cr21Al6 Nb | 0Cr27Al7Mo2 | |

| Lub ntsiab Chemical Composition (%) | Cr | 12.0-15.0 Nws | 23.0-26.0 Nws | 19.0-22.0 Nws | 22.5-24.5 Nws | 18.0-21.0 Nws | 21.0-23.0 Nws | 26.5-27.8 Nws |

| Al | 4.0-6.0 | 4.5-6.5 | 5.0-7.0 Nws | 4.2-5.0 | 3.0-4.2 | 5.0-7.0 Nws | 6.0-7.0 Nws | |

| Re | muaj caij nyoog | muaj caij nyoog | muaj caij nyoog | muaj caij nyoog | muaj caij nyoog | muaj caij nyoog | muaj caij nyoog | |

| Fe | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | Bal. | |

| n0.5 ib | Mo1.8-2.2 | |||||||

| Max Continuous Service Temperature (oC) | 950 ua | 1250 | 1250 | 1250 | 1100 | 1350 | 1400 | |

| Resisivity 20oC (Ωmm2 / m) | 1.25 ± 0.08 hli | 1.42 ib ± 0.06 | 1.42 ib ± 0.07 hli | 1.35 Nws ± 0.07 hli | 1.23 ± 0.07 hli | 1.45 Nws ± 0.07 hli | 1.53 ib ± 0.07 hli | |

| Qhov ceev (g / cm3) | 7.4 ib | 7.1 | 7.16 | 7.25 Nws | 7.35 Nws | 7.1 | 7.1 | |

| Thermal conductivity | 52.7 ib | 46.1 ib | 63.2 ib | 60.2 ib | 46.9 ua | 46.1 ib | 45.2 ib | |

| (KJ/m@h@oC) | ||||||||

| Coefficient ntawm Thermal Expansion (α × 10-6 / oC) | 15.4 ib | 16 | 14.7 ib | 15 | 13.5 Nws | 16 | 16 | |

| Kwv yees Melting Point (oC) | 1450 | 1500 | 1500 | 1500 | 1500 | 1510 | 1520 | |

| Tensile zog (N / mm2) | 580-680 : kuv | 630-780 : kuv | 630-780 : kuv | 630-780 : kuv | 600-700 Nws | 650-800 Nws | 680-830 : kuv | |

| Elongation (%) | > 16 | > 12 | > 12 | > 12 | > 12 | > 12 | > 10 | |

| Tshooj Variation | 65-75 : kuv | 60-75 : kuv | 65-75 : kuv | 65-75 : kuv | 65-75 : kuv | 65-75 : kuv | 65-75 : kuv | |

| Shrink Rate (%) | ||||||||

| Repeedly Khoov zaus (F / R) | > 5 | > 5 | > 5 | > 5 | > 5 | > 5 | > 5 | |

| Hardness (HB) | 200-260 Nws | 200-260 Nws | 200-260 Nws | 200-260 Nws | 200-260 Nws | 200-260 Nws | 200-260 Nws | |

| Lub Sijhawm Kev Pabcuam Nruam | no | ≥80/1300 | ≥80/1300 | ≥80/1300 | ≥80/1250 | ≥50/1350 | ≥50/1350 | |

| Micrographic Structure | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | Ferrite | |

| Magnetic Property | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | Sib nqus | |