Txais tos rau peb lub vev xaib!

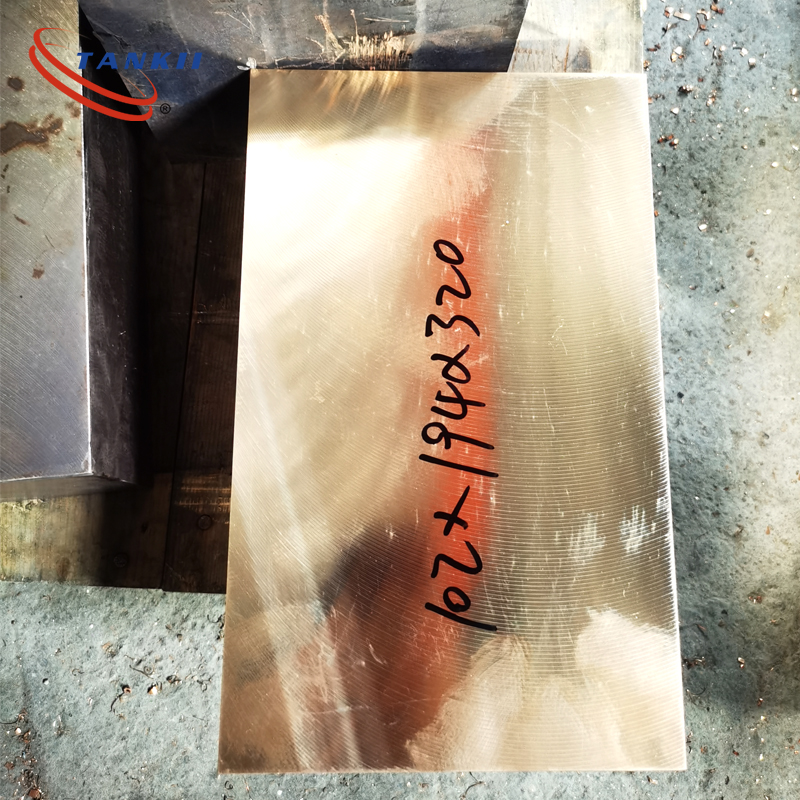

Beryllium Copper C17200 C17300 C17510 Qbe2 Alloy Sawb Ntawv Nyiaj Phaj

| Khoom npe | 0.08-2mm Thickness Alloy 25 Beryllium Copper strips |

| Khoom siv | Beryllium tooj liab Alloys |

| Kev sib xyaw | 1.86% Co + Ni 0.265% Fe 0.06% Co + Ni + Fe 0.325% Cu Balance |

| Cov duab | Roll//Strips/coils |

| UNS/CDA | UNS: C17200, CDA: 172 |

| ASTM | B194 |

| AMS | 4530, 4532 ib |

| RWM | Chav Kawm 4 |

| Kub | A(TB00), 1/4H(TD01), 1/2H(TD02), H(TD04) |

Lub cev muaj zog

Qhov ceev (g / cm3): 8.36

Qhov ceev ua ntej hnub nyoog hardening (g / cm3): 8.25

Elastic Modulus (kg / mm2 (103)): 13.40

Thermal Expansion Coefficient (20 ° C txog 200 ° C m / m / ° C): 17 x 10-6

Thermal conductivity (cal/(cm-s-°C)): 0.25

Melting Range (°C): 870-980°C

Nco tseg:

1).cov units yog raws li Metric.

2).cov khoom siv lub cev raug siv rau cov khoom uas muaj hnub nyoog tawv.

Qhov ceev ua ntej hnub nyoog hardening (g / cm3): 8.25

Elastic Modulus (kg / mm2 (103)): 13.40

Thermal Expansion Coefficient (20 ° C txog 200 ° C m / m / ° C): 17 x 10-6

Thermal conductivity (cal/(cm-s-°C)): 0.25

Melting Range (°C): 870-980°C

Nco tseg:

1).cov units yog raws li Metric.

2).cov khoom siv lub cev raug siv rau cov khoom uas muaj hnub nyoog tawv.

Daim ntawv thov:

1).Kev Lag Luam Hluav Taws Xob: Hluav Taws Xob Hloov thiab Relay Blades

2).Fuse Clips, Hloov Qhov Chaw, Relay qhov chaw, Txuas Txuas, Caij nplooj ntoos hlav txuas

3).Hu rau Bridges, Belleville Washers, Navigational Instruments

4).Clips Fasteners: Washers, Fasteners, Lock Washers

5).Retaining Rings, Roll Pins, Screws, Bolts Muaj: Twj, Springs,

6).Electrochemical, Shafts, Non Sparking Safety Tools, Saj zawg zog Hlau Hose,

7).Vaj Tsev Rau Cov Cuab Yeej, Bearings, Bushings, Valve Rooj, Valve Stems,

8).Diaphragms, Springs, Vuam khoom, Rolling Mill Parts,

9).Spline Shafts, Pump Parts, Valves, Bourdon Tubes, Hnav daim hlau ntawm cov khoom hnyav.

2).Fuse Clips, Hloov Qhov Chaw, Relay qhov chaw, Txuas Txuas, Caij nplooj ntoos hlav txuas

3).Hu rau Bridges, Belleville Washers, Navigational Instruments

4).Clips Fasteners: Washers, Fasteners, Lock Washers

5).Retaining Rings, Roll Pins, Screws, Bolts Muaj: Twj, Springs,

6).Electrochemical, Shafts, Non Sparking Safety Tools, Saj zawg zog Hlau Hose,

7).Vaj Tsev Rau Cov Cuab Yeej, Bearings, Bushings, Valve Rooj, Valve Stems,

8).Diaphragms, Springs, Vuam khoom, Rolling Mill Parts,

9).Spline Shafts, Pump Parts, Valves, Bourdon Tubes, Hnav daim hlau ntawm cov khoom hnyav.

Ntau yam khoom:

Ntau ntau ntawm tooj liab thiab tooj liab alloys, nyob rau hauv tag nrho cov duab ntawm cov duab: Sheet, Qws, Yeeb Nkab, Strips thiab Hlau daim ntawv teev npe hauv qab no:

C17000/170 (CuBe1.7, 2.1245, Alloy165)

C17200/172 (CuBe2, 2.1247, Alloy25)

C17300/173 (CuBe2Pb, 2.1248, AlloyM25)

C17500/175 (CuCo2Be, 2.1285, Alloy10)

C17510/1751 (CuNi2Be, 2.0850, Alloy3)

CuCoNiBe (CuCo1Ni1Be, 2.1285, CW103C)

C15000/150 C18000/180 C18150/181 C18200/182

CuZr, CuNi2CrSi, CuCr1Zr, CuCr

C17200/172 (CuBe2, 2.1247, Alloy25)

C17300/173 (CuBe2Pb, 2.1248, AlloyM25)

C17500/175 (CuCo2Be, 2.1285, Alloy10)

C17510/1751 (CuNi2Be, 2.0850, Alloy3)

CuCoNiBe (CuCo1Ni1Be, 2.1285, CW103C)

C15000/150 C18000/180 C18150/181 C18200/182

CuZr, CuNi2CrSi, CuCr1Zr, CuCr

Sau koj cov lus ntawm no thiab xa tuaj rau peb