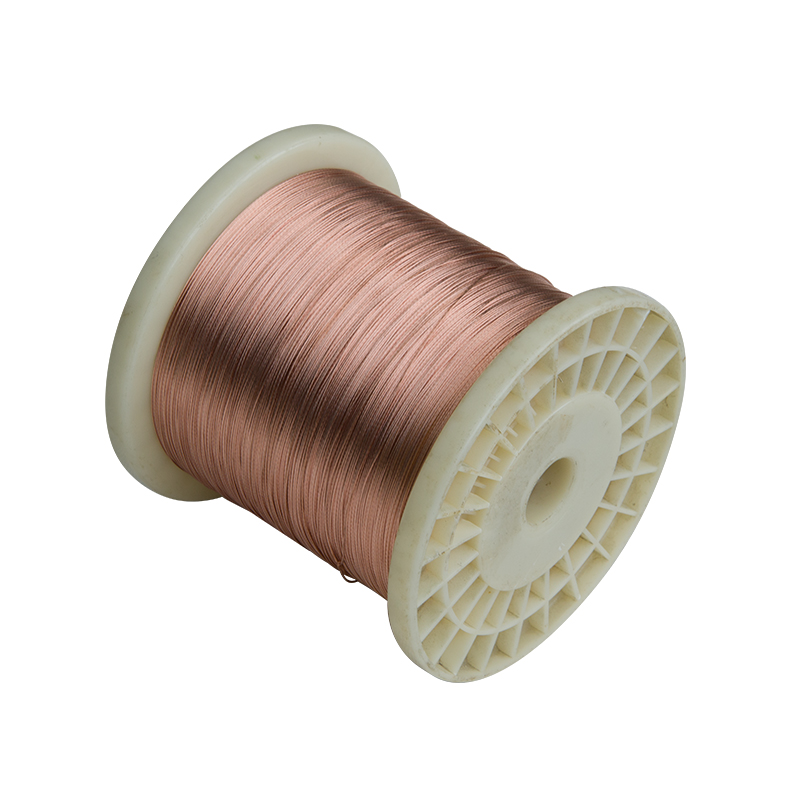

Beryllium Copper Wire Aging Process C17200 Cube2 0.5mm-6mm rau Caij nplooj ntoos hlav

Beryllium-Copper-alloys feem ntau yog ua los ntawm tooj liab nrog beryllium ntxiv.Lub zog loj beryllium tooj liab alloys muaj 0.4-2% ntawm beryllium nrog txog 0.3 mus rau 2.7% ntawm lwm cov alloying ntsiab xws li npib tsib xee, cobalt, hlau los yog Lead.Lub siab mechanical zog yog ua tiav los ntawm nag lossis daus hardening lossis hnub nyoog hardening.

Nws yog cov khoom siv high-elastic zoo tshaj plaws hauv tooj liab alloy.Nws muaj lub zog siab, elasticity, hardness, qaug zog, tsis tshua muaj elastic hysteresis, corrosion kuj, hnav tsis kam, txias tsis kam, siab conductivity, tsis muaj hlau nplaum, tsis muaj kev cuam tshuam, tsis muaj sparks, thiab lwm yam.

Kev kho cua sov

Kev kho cua sov yog cov txheej txheem tseem ceeb tshaj plaws rau cov txheej txheem alloy no.Thaum tag nrho cov tooj liab alloys yog hardenable los ntawm kev ua hauj lwm txias, beryllium tooj liab yog tshwj xeeb nyob rau hauv ua hardenable los ntawm ib tug yooj yim uas tsis muaj thermal kho.Nws muaj ob theem pib.Thawj yog hu ua kua annealing thiab thib ob, nag lossis daus los yog hnub nyoog hardening.

Kev daws Annealing

Rau qhov raug alloy CuBe1.9 (1.8- 2%) cov hlau yog rhuab ntawm 720 ° C thiab 860 ° C.Nyob rau lub sijhawm no, cov khoom muaj beryllium yog qhov tseem ceeb "kua" hauv tooj liab matrix (alpha theem).Los ntawm ceev ceev quenching mus rau chav tsev kub no cov qauv kev daws teeb meem yog khaws cia.Cov khoom siv nyob rau theem no yog mos thiab ductile thiab tuaj yeem ua haujlwm txias los ntawm kev kos duab, sib sau dov, lossis txias taub hau.Cov kev daws teeb meem annealing yog ib feem ntawm cov txheej txheem ntawm lub zeb thiab tsis yog feem ntau siv los ntawm cov neeg siv khoom.Kub, lub sij hawm ntawm qhov kub thiab txias, quench npaum li cas, grain loj, thiab hardness yog tag nrho cov tseem ceeb heev tsis thiab yog nruj me ntsis tswj los ntawm tankii.

shanghai tankii alloy Material Co., Ltd's CuBe Alloy muab ntau yam khoom tshwj xeeb uas tsim nyog kom ua tau raws li qhov xav tau ntawm ntau daim ntawv thov hauv tsheb, hluav taws xob, aeronautical, Roj & Roj, saib, electro-chemical industries, thiab lwm yam.Beryllium tooj liabyog dav siv nyob rau hauv cov teb raws li kev sib cuag springs nyob rau hauv ntau yam kev siv xws li connectors, keyboards, relays, thiab lwm yam