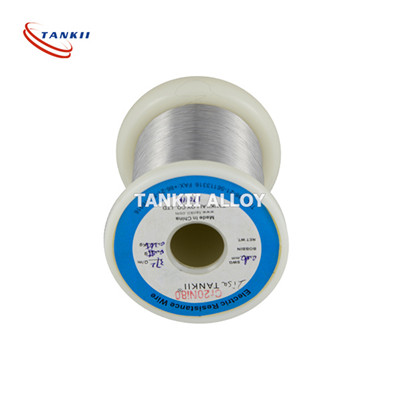

Tooj Liab Nickel Alloy Hlau

Kev piav qhia txog khoom

Cov hlau tooj liab Nickel (CuNi) yog cov khoom siv tiv taus nruab nrab mus rau qis uas feem ntau siv rau hauv cov ntawv thov nrog qhov kub siab tshaj plaws txog li 400 ° C (750 ° F).

Nrog cov coefficients kub qis ntawm kev tiv thaiv hluav taws xob, kev tiv thaiv, thiab yog li ntawd kev ua tau zoo, yog sib xws tsis hais qhov kub thiab txias. Cov tooj liab Nickel alloys mechanically khav theeb zoo ductility, yooj yim soldered thiab welded, nrog rau muaj kev tiv thaiv corrosion zoo heev. Cov alloys no feem ntau yog siv rau hauv cov ntawv thov tam sim no siab uas xav tau qib siab ntawm kev raug.

Tooj liab-puag tshav kub tsis kam hlau alloy hlau resistivity yog qis, muaj corrosion zoo, vuam khoom thiab machinable khoom, tsim nyog rau hauv thermal overload relay, lub low-voltage circuit breakers, thiab lwm yam khoom siv hluav taws xob qis-voltage thiab cov khoom siv hauv tsev thiab lwm yam khoom siv hluav taws xob tsim cov khoom cua sov, thiab yog ib qho khoom siv tseem ceeb hauv kev tsim cov cua sov cable.

| Cov Cai | Kev tiv taus | Ma.Ua Haujlwm Temper | Kub.Coeffi. Ntawm Kev Tiv Thaiv | EMF Tawm Tsam Tooj Liab (0 ~ 100 ℃) | Cov Tshuaj Muaj pes tsawg leeg (%) | Mechanical, Cov Khoom | |||||

| Mn | Ni | Cu | Lub zog tensile (N/mm)2) | Kev Ntev % (Tsawg dua) | |||||||

| Txoj kab uas hla <= 1.0 hli | Txoj kab uas hla> = 1.0 hli | ||||||||||

| NC003 | CuNi1 | 0.03 | 200 | <100 | -8 | - | 1 | So | 210 | 18 | 25 |

| NC005 | CuNi2 | 0.05 | 200 | <120 | -12 | - | 2 | So | 220 | 18 | 25 |

| NC010 | CuNi6 | 0.10 | 220 | <60 | -18 | - | 6 | So | 250 | 18 | 25 |

| NC012 | CuNi8 | 0.12 | 250 | <57 | -22 | - | 8 | So | 270 | 18 | 25 |

| NC015 | CuNi10 | 0.15 | 250 | <50 | -25 | - | 10 | So | 290 | 20 | 25 |

| NC020 | CuNi14 | 0.20 | 250 | <38 | -28 | 0.3 | 14.2 | So | 310 | 20 | 25 |

| NC025 | CuNi19 | 0.25 | 300 | <25 | -32 | 0.5 | 19 | So | 340 | 20 | 25 |

| NC030 | CuNi23 | 0.30 | 300 | <16 | -34 | 0.5 | 23 | So | 350 | 20 | 25 |

| NC035 | CuNi30 | 0.35 | 300 | <10 | -37 | 1.0 | 30 | So | 400 | 20 | 25 |

| NC040 | CuNi34 | 0.40 | 350 | 0 | -39 | 1.0 | 34 | So | 400 | 20 | 25 |

| NC050 | CuNi44 | 0.50 | 400 | <-6 | -43 | 1.0 | 34 | So | 420 | 20 | 25 |

| Cov hlau nplaum | DN-Lub Npe Lag Luam | Khoom siv-Tsis muaj. | UNS-Tsis muaj. | ASTM Cov Lus Qhia Tshwj Xeeb | Cov Lus Qhia Txog DIN |

| CuNi1 | CuNi1 | ||||

| CuNi2 | CuNi2 | 2.0802 | C70200 | ASTM B267 | DIN 17471 |

| CuNi6 | CuNi6 | 2.0807 | C70500 | ASTM B267 | DIN 17471 |

| CuNi10 | CuNi10 | 2.0811 | C70700 | ASTM B267 | DIN 17471 |

| CuNi10Fe1Mn | CuNi10Fe1Mn | (2.0872) / (CW352H) | C70600 | ASTM B151 | |

| CuNi15 | CuNi15 | ||||

| CuNi23Mn | CuNi23Mn | 2.0881 | C71100 | ASTM B267 | DIN 17471 |

| CuNi30Mn | CuNi30Mn | 2.0890 | |||

| CuNi30Mn1Fe | CuNi30Mn1Fe | (2.0882) / (CW354H) | C71500 | ASTM B151 | |

| CuNi44Mn1 | Vernicon | 2.0842 | DIN 17471 |

294: Lub Npe Feem Ntau:

Alloy294, Cuprothal294, Nico, MWS-294, Cupron, Copel, Alloy45, Cu-Ni102, Cu-Ni44, Cuprothal, Cupron, Copel, Neutrology, Advance, Konstantan

A30: Lub Npe Feem Ntau:

Alloy 30, MWS-30, Cuprothal 5, Cu-Ni 23, Alloy 260, Cuprothal 30 HAI-30, Cu-Ni2, Alloy 230, Nickel Alloy 30

A90: Lub Npe Feem Ntau:

Cov hlau nplaum 95, 90 Cov hlau nplaum, MWS-90, Cu-Ni 10, Cuprothal 15, Cu-Ni 10, Cov hlau nplaum 320 Cov hlau nplaum 90, Cov hlau nplaum 290, # 95 Cov hlau nplaum, Cuprothal 90, HAI-90, Cov hlau nplaum 260, Cov hlau nplaum Nickel 90

A180: Lub Npe Feem Ntau:

Cov hlau nplaum 180, 180 Cov hlau nplaum, MWS-180, Cuprothal 30, Midohm, Cu-Ni 23, Cov hlau nplaum Nickel 180

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj