Tooj liab Nickel Alloy Hlau

Khoom Piav Qhia

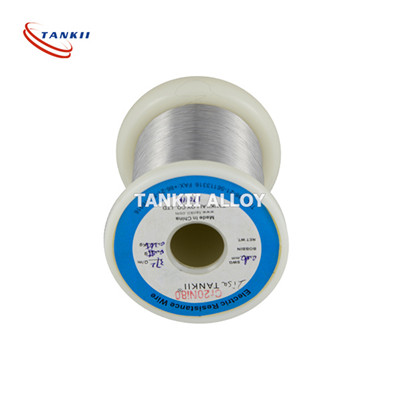

Tooj liab npib (cuni) alloys yog nruab nrab rau cov khoom siv tsis tshua muaj siv nyob rau hauv cov kev ua haujlwm ntau tshaj li 400 ° C (750 ° F).

Nrog tsawg coefficients ntawm cov hluav taws xob tsis kam, tsis kam, thiab yog li kev ua haujlwm, zoo li tsis suav hais tias kub. Tooj liab Nickel alloys tau yooj yim thiab muab tso tawm yooj yim thiab welded, zoo li muaj cov khoom siv corrosion. Cov alloys feem ntau siv hauv cov ntawv thov siab tam sim no xav tau theem siab ntawm qhov tseeb.

Copper-base heat resistance alloy wire resistivity is low, has good corrosion resistance, welding property and machinable property , suitable for in thermal overload relay, a low-voltage circuit breakers, and other low- voltage electrical appliances and household appliances and other electrical appliances manufacturing heating element, and is an important material in production of heating cable.

| Txoj cai | Resiveivity | Ma.Working Tauj | Temp.coffi. Ntawm tsis kam | EMF tiv thaiv tooj liab (0 ~ 100 ℃) | Tshuaj lom neeg muaj pes tsawg leeg (%) | Mechanical, Khoom | |||||

| Mn | Ni | Cu | Tensile lub zog (n / hli2) | Elongation% (tsawg dua) | |||||||

| Inch <= 1.0mm | Txoj Internch> = 1.0mm | ||||||||||

| Nc003 | Cuni1 | 0.03 | 200 | <100 | -8 | - | 1 | So | 210 | 18 | 25 |

| NC005 | Cuni2 | 0.05 | 200 | <120 | -12 | - | 2 | So | 220 | 18 | 25 |

| NC010 | Cuni6 | 0.10 | 220 | <60 | -18 | - | 6 | So | 250 | 18 | 25 |

| NC012 | Cuni8 | 0.12 | 250 | <57 | -22 | - | 8 | So | 270 | 18 | 25 |

| NC015 | Cuni10 | 0.15 | 250 | <50 | -25 | - | 10 | So | 290 | 20 | 25 |

| Nc020 | Cuni14 | 0.20 | 250 | <38 | -28 | 0.3 | 14.2 | So | 310 | 20 | 25 |

| NC025 | Cuni19 | 0.25 | 300 | <br 25 | -2 | 0.5 | 19 | So | 340 | 20 | 25 |

| Nc030 | Cuni23 | 0.30 | 300 | <16 | -4 | 0.5 | 23 | So | 350 | 20 | 25 |

| NC035 | Cuni30 | 0.35 | 300 | <10 | -37 | 1.0 | 30 | So | 400 | 20 | 25 |

| Nc040 | Cuni34 | 0.40 | 350 | 0 | -39 | 1.0 | 34 | So | 400 | 20 | 25 |

| Nc050 | Cuni44 | 0.50 | 400 | <-6 | - | 1.0 | 34 | So | 420 | 20 | 25 |

| Hlau | DN-luam lub npe | Cov khoom siv - tsis muaj. | Tsis muaj. | Astm Kev Tshawb Fawb | DIN TXHAWB |

| Cuni1 | Cuni1 | ||||

| Cuni2 | Cuni2 | 2.0802 | C70200 | ASTM B267 | DIN 17471 |

| Cuni6 | Cuni6 | 2.0807 | C70500 | ASTM B267 | DIN 17471 |

| Cuni10 | Cuni10 | 2.0811 | C70700 | ASTM B267 | DIN 17471 |

| Cuni10fe1mn | Cuni10fe1mn | (2.0872) / (CW352h) | C70600 | ASTM B151 | |

| Cuni15 | Cuni15 | ||||

| Cuni23mn | Cuni23mn | 2.0881 | C71100 | ASTM B267 | DIN 17471 |

| Cuni30mn | Cuni30mn | 2.0890 | |||

| Cuni30mn1fe | Cuni30mn1fe | (2.0882) / (CW354h) | C71500 | ASTM B151 | |

| Cuni44mn1 | Tus vernicon | 2.0842 | DIN 17471 |

294: Hom Lub Npe:

Alloy294, Cuprothat294, Nico, MMS-294, cuprothal, Alloy44, Cuprothal, Copel, Neutrology, Ua ntej, Konstantan

A30: Lub Npe:

Alloy 30, Mws-30, CuProthal 5, CuProthhal 5, CuProthhal 5, inelot 260, Cu-Ni2, Alloy 230, Nickoy Alloy 30

A90: Lub Npe:

Alloy 95, 90 alloy, MNS-90, Cu-Ni 10, ujole 320 alloy 90, Hai-90, Nickoy 260, Nickel Alloy 90

A180: Lub npe nquag:

Alloy 180, 180 alloy, mws-180, cuprothhal 30, MIDOHM, CU-NI 23, Nickel Alloy 180