Dia 0.04mm 0Cr15Al5 Fecral 750 Alloy Hlau Rau Rauv

0r15Al5 FeCrAlHluav taws xob cua sovResistance Alloy Hlau rau Rauv

Taw qhia

1) Alloy qib:

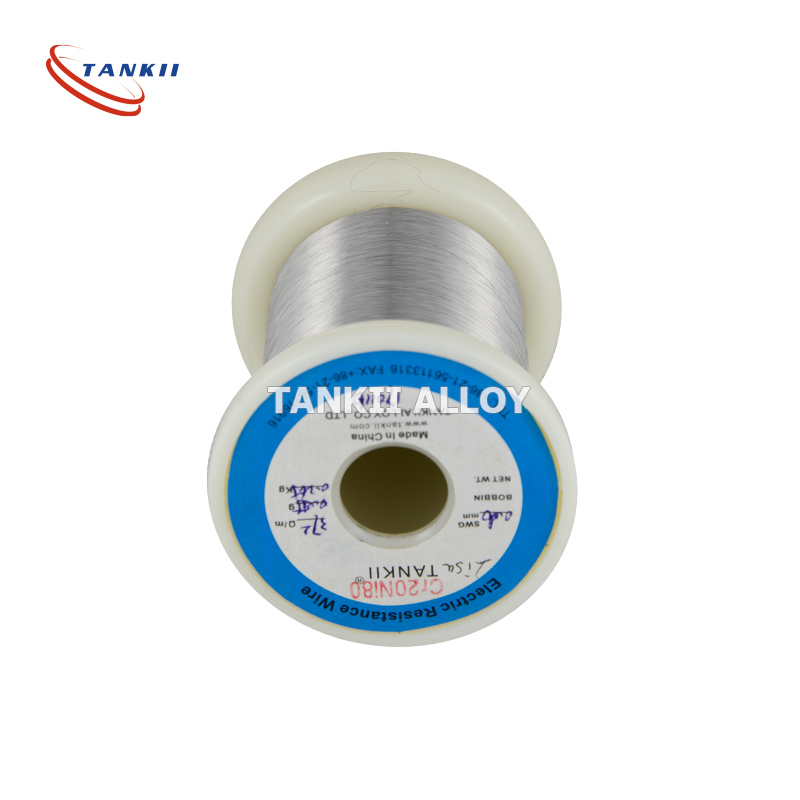

OCr21Al4, OCr21Al6, OCr25Al5, OCr23Al5, 1Cr13Al4, OCr21Al6Nb, Cr15Ni60, Cr20Ni80, Cr30Ni70, Cr20Ni30 thiab lwm yam.

Peb yog cov kws tshaj lij kev lag luam ntawm cov cua kub cua sov hauv Suav teb, tshwj xeeb hauv Ferro-Chrome Alloys (Ferritic Alloys), Nickel-Chrome Alloys (Nichrome alloys), Copper Nickel Alloys (Constantan Alloys)

Nyob rau hauv daim ntawv ntawm hlau, ribbon / sawb:

Round Hlau: Dia 0.04mm-8.0mm

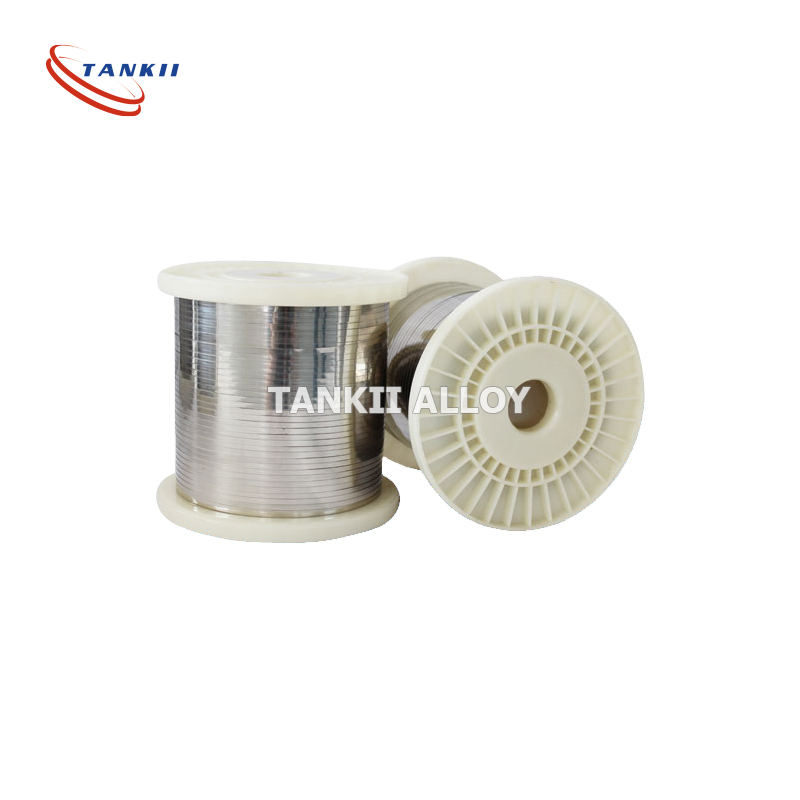

Ribbon / sawb: Thickness: 0.04mm-0.75mm

Dav: 0.08mm-10mm

| Max Continuous Service Temperature: Kev kub siab 20 ℃ Ceev: Thermal conductivity: Coefficient ntawm Thermal Expansion: Melting Point: Elongation: Micrographic Structure: Magnetic Property: | 1300 ºC 1.35 +/- 0.06ohm mm2 / m 7.25g / cm3 60.2 KJ/m @ h@'C 15.0 × 10-6 / 'C (20'C ~ 1000'C) 1500′C Tsawg tshaj 12% Ferrite Sib nqus |

2) Khoom Specifications:

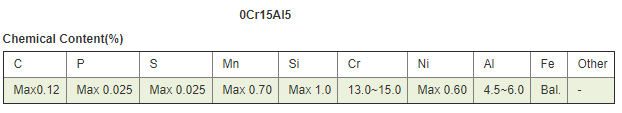

Ferro-Chrome Alloys (Ferritic Alloys):

OCr21AL4, OCr21AL6, OCr25AL5, OCr23AL5, 1Cr13AL4, OCr21AL6Nb, OCr27AL7Mo2.

Nickel-Chrome Alloys (Ni-Cu Alloys):

Cr20Ni80, Cr15Ni60, Cr30Ni70, Cr20Ni30

Constantan Alloys (Cu-Ni Alloys):

CuNi1, CuNi2, CuNi6, CuNi8, CuNi10, CuNi14, CuNi19, CuNi23, CuNi30, CuNi44, Manganin.

3) High quality assured:

Peb cov haujlwm muaj cov lus txib zoo ntawm cov txheej txheem thev naus laus zis hauv kev hwm ntawm smelting, dov, kos duab thiab kho cua sov mus txog rau cov khoom tiav, ua ke nrog lub tuam tsev tshuaj ntsuam xyuas, lub tuam tsev kuaj lub cev thiab lub chaw tswj xyuas qhov zoo, peb ua haujlwm tag nrho. kev soj ntsuam ntawm peb cov khoom los ntawm cov khoom siv raw mus rau cov khoom kawg.

4) Kev Siv: Cov khoom siv hluav taws xob tiv thaiv cua sov;Khoom siv hauv metallurgy;Cov khoom siv hauv tsev;Mechanical manufacturing thiab lwm yam kev lag luam.

5) Peb kuj tuaj yeem muab lwm cov khoom lag luam los ntawm kev ua raws li koj qhov kev txiav txim: Stranded wire, twisted wire, coiled wire, yoj-shaped wires thiab ntau hom qauv lossis tsis yog qauv hluav taws xob cua sov.

Shanghai TANKII ALLOY khoom Co., Ltd.

FECRAL THIAB ALCHROME ALLOY PRODUCER nyob rau hauv Suav teb, feem ntau tshaj lij nyob rau hauv lub ntiaj teb no