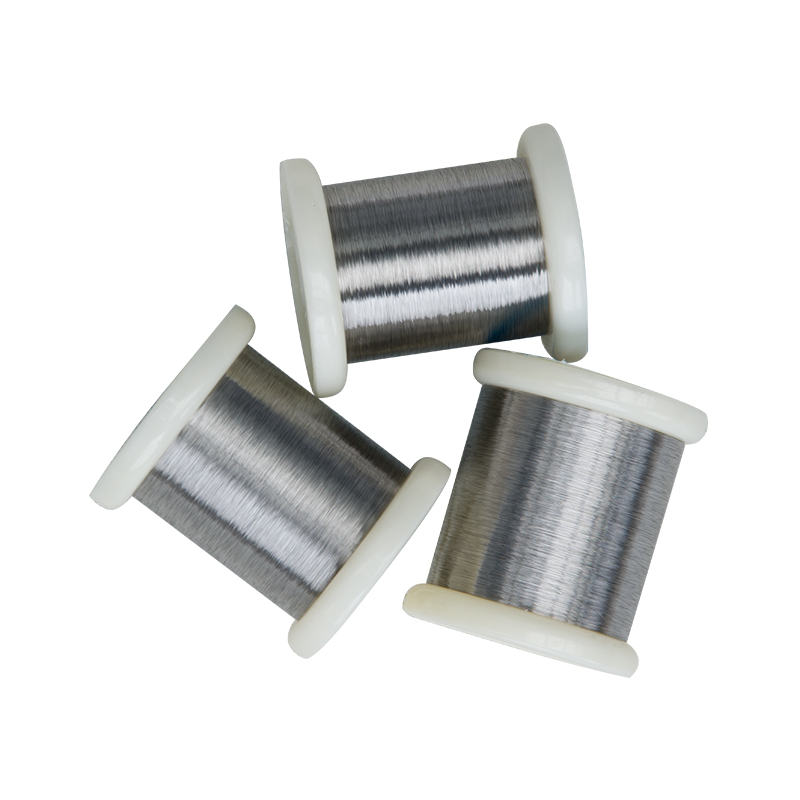

Nickel Alloy Hastelloy C276 Ernicrmo-4 Vuam MIG TIG Vuam Inconel C-276 C22, B3, B2 Hlau

Hastelloy yog ib qho hlau uas tsis yooj yim xeb uas ua los ntawm nickel, uas feem ntau muab faib ua ob pawg: nickel-chromium alloy thiab nickel-chromium-molybdenum alloy. Hastelloy muaj kev tiv thaiv corrosion zoo thiab thermal stability, thiab feem ntau yog siv rau hauv kev tsav dav hlau, tshuaj lom neeg, thiab lwm yam.

ERNiCrMo-4yog siv rau kev vuam roj-tungsten-arc thiab roj-hlau-arc ntawm Inconel alloy C-276 thiab lwm yam nickel-chromium-molybdenum alloys. Vim muaj cov ntsiab lus molybdenum siab, cov alloy no muaj kev tiv thaiv zoo heev rau kev ntxhov siab corrosion cracking thiab pitting thiab crevice corrosion.

Cov Npe Feem Ntau: Oxford Alloy® C-276 FM C-276 Techalloy 276

Tus Qauv: AWS A5.14,ERNiCrMo-4/ ASME II, SFA-5.14, UNS N10276 Werkstoff Nr. 2.4886 ISO SNi6276 Teb chaws Europe NiCrMo16Fe6W4

Loj: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

| Qib | C276 | C22 | C4 | N | |||

|

Tshuaj lom neeg Kev sau ua ke (%) | C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

| Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 | |

| Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 | |

| P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | – | ≤0.015 | |

| S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | – | ≤0.02 | |

| Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 | |

| Ni | so | so | so | so | ≥65 | so | |

| Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 | |

| Ti + Cu | – | – | ≤0.7 | – | ≤0.4 | ≤0.35 | |

| Al+Ti | – | – | – | – | ≤0.5 | ≤0.5 | |

| Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 | |

| Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 | |

| B | – | – | – | – | – | ≤0.01 | |

| W | 3-4.5 | 2.5-3.5 | – | – | ≤3 | ≤0.5 | |

| V | ≤0.35 | ≤0.35 | – | 0.2-0.4 | – | ≤0.5 | |

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj