Ntshiab npib tsib xee tsis kam

Ntshiab npib tsib xee tsis kam

Ntshiab Nickel xaim muaj cov yam ntxwv ntawm lub zog zoo ntawm qhov kub, zoo thermal conductivity thiab siab tsis kam.

Chaw thov

Hlau: Cov Hom Phiaj Chaw, Evaporation Pellets, Regulator Chev nyob rau hauv Glow Stands ntawm Diesel Xyaw; Litz hlau rau tam sim no kev ua kom sov thiab siv cov khoom siv hlau, cov khoom siv hlau rau cov roj xaim xaim, txheej thermal rau kev tiv thaiv corrosion los ntawm alkalis; ntsev tsuag; molten ntsev thiab reduciing tshuaj; Txheej txheej txheej rau cov kub ua tsis taus; Corrosion tiv thaiv ntawm qhov kub; Txheej Txheej Txheej Rau Mihab Phab Ntsa Ntawm Fais Fab

Keeb Kwm Ua

Rau kev tsim cov hlau, lub 6 hli kub dov tuab daim hlau yog txiav rau hauv 6 Mm dav. Cov kab yog cov kab hauv qab. Tom qab cov xaim nyoos tuaj yeem kho tau tib yam li kub dov hlau tsim los ntawm Melt Metallurgy. Raws li, cov hlau yog kos rau cov qhov ntev xav tau los ntawm kev kos kab mob khaub thuas thiab nruab nrab nruab nrab.

Nto tas

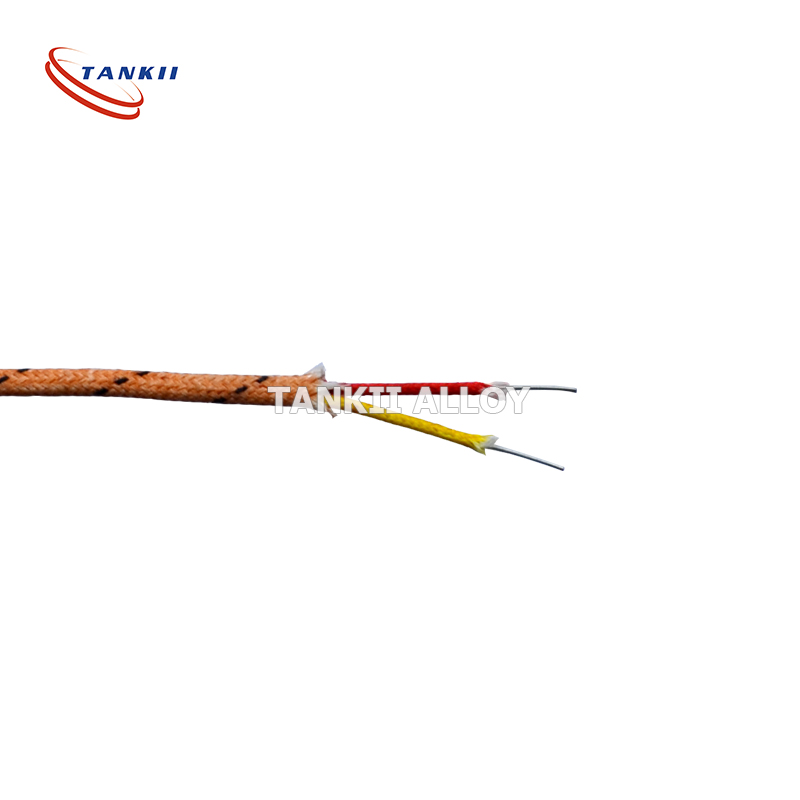

Dawb paug / liab qab / ci saum npoo

| Ntshiab npib tsib xee tsis kam | |

| Teem nqi | Ni200, ni201, ni205 |

| Qhov loj | Hlau: ill0.1-12mm |

| Nta | Cov neeg kho tshuab zoo zog, corrosion tsis kam thiab siab tiv lub zog. Nws yog qhov haum rau kev ua cov tshuab nqus tsev, Cheebtsam hauv hluav taws xob, thiab cov ntxaij lim dej rau cov tshuaj lom neeg muaj zog. |

| Daim ntawv thov | Xov tooj cua, hluav taws xob teeb pom kev, kev tsim khoom siv tau, kev lag luam tshuaj, thiab yog ib qho khoom siv tseem ceeb hauv kev siv hluav taws xob. |

Tshuaj lom neeg tshuaj lom neeg (WT.%)

| Qeb Nickel | Ni + cool | Cu | Si | Mn | C | Cr | S | Fe | Mg |

| ≥ | ≤ | ||||||||

| Ni201 | 99.2 | Cov .25 | .3 | .35 | .02 | .2 | .01 | .3 | - |

| Ni200 | 99.0 | Cov .25 | .3 | .35 | Cov .15 | .2 | .01 | .3 | - |

Cov Khoom Siv Neeg Kho Tshuab

| Teem nqi | Yam tseem ceeb | Inch (hli) | Lub zog tensile N / mm2, min | Elongation,%, min |

| Ni200 | M | 0.03-0.20 | 373 | 15 |

| 0.21-0.48 | 343 | 20 | ||

| 0.50-1.00 | 314 | 20 | ||

| 1.05-6.00 | 294 | 25 | ||

| 1 / 2y | 0.10-0.50 | 686-883 | - | |

| 0.53-1.00 | 588-785 | - | ||

| 1.05-5.00 | 490-637 | - | ||

| Y | 0.03-0.09 | 785-1275 | - | |

| 0.10-0.50 | 735-981 | - | ||

| 0.53-1.00 | 686-883 | - | ||

| 1.05-6.00 | 539-834 | - | ||

| Ni201 | M | 0.03-0.20 | 422 | 15 |

| 0.21-0.48 | 392 | 20 | ||

| 0.50-1.00 | 373 | 20 | ||

| 1.05-6.00 | 343 | 25 | ||

| 1 / 2y | 0.10-0.50 | 785-981 | - | |

| 0.53-1.00 | 686-834 | - | ||

| 1.05-5.00 | 539-686 | - | ||

| Y | 0.03-0.09 | 883-1325 | - | |

| 0.10-0.50 | 834-1079 | - | ||

| 0.53-1.00 | 735-981 | - | ||

| 1.05-6.00 | 637-883 | - |

Qho loj davthiab kev kam (hli)

| Qhov dav | 0.025-0.03 | > 0.03-0.10 | > 0.10-0.40 | > 0.40-0.80 | > 0.80-1.20 | > 1.20-200 |

| Kev nyiaj tau | ± 0.0025 | ± 0.005 | 0.006 | ± 0.013 | ± 0.02 | ± 0.03 |

Hais lus:

1). Mob: m = mos.1 / 2y = 1 / 2hard, y = nyuaj

2). Yog tias koj tau tiv taus tsis kam, kuj peb yaj rau koj.