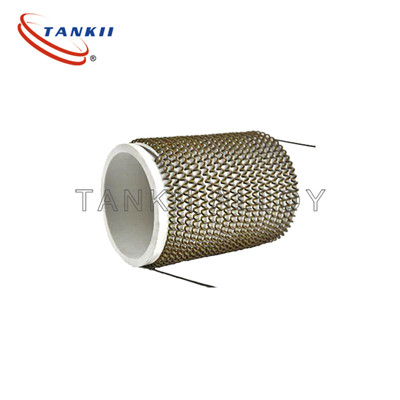

Caij nplooj ntoos hlav Coil

pkev piav qhia txog khoom

Peb lub tuam txhab tsim cov hlau hluav taws xob zoo hlau-chromium-aluminium thiab nickel-chromium hluav taws xob cua sov hlau, uas siv lub khoos phis tawj tswj hwm lub zog hluav taws xob thiab raug qhwv rau hauv cov duab los ntawm lub tshuab winding ceev ceev. Cov yam ntxwv ntawm cov khoom no: tiv taus kub siab, cua sov sai, kev pabcuam ntev, kev tiv taus ruaj khov, kev hloov pauv hluav taws xob me me, lub suab sib npaug tom qab ncab, qhov chaw ci thiab huv; siv dav hauv cov cub hluav taws xob me me, cov cub tawg muffle, cov khoom siv cua sov thiab cua txias, ntau yam cub, cov raj cua sov hluav taws xob thiab cov khoom siv hauv tsev, thiab lwm yam. Ntau yam tsis yog tus qauv rau kev lag luam thiab pej xeem cub hluav taws xob tuaj yeem tsim thiab tsim raws li cov neeg siv xav tau.

| Lub zog W | Voltage V | Txoj kab uas hla hli | OD hli | Lntev (Siv) hli | Wyim g |

| 300 | 220 | 0.25 | 3.7 | 122 | 1.9 |

| 500 | 220 | 0.35 | 3.9 | 196 | 4.3 |

| 600 | 220 | 0.40 | 4.2 | 228 | 6.1 |

| 800 | 220 | 0.50 | 4.7 | 302 | 11.1 |

| 1000 | 220 | 0.60 | 4.9 | 407 | 18.5 |

| 1200 | 220 | 0.70 | 5.6 | 474 | 28.5 |

| 1500 xyoo | 220 | 0.80 | 5.8 | 554 | 39.0 |

| 2000 xyoo | 220 | 0.95 | 6.1 | 676 | 57.9 |

| 2500 | 220 | 1.10 | 6.9 | 745 | 83.3 |

| 3000 | 220 | 1.20 | 7.1 | 792 | 98.3 |

Qhov kub thiab tshuaj lom neeg ntawm cov xov hlau cua sov

| Qib | Max. Txuas ntxiv mus Kev Ua Haujlwm Kub. | Cr% | Ni% | Al% | Fe% | Rov qab% | Nb% | Mo% |

| Cr20Ni80 | 1200 ℃ | 20~23 | Bal. |

|

|

|

|

|

| Cr30Ni70 | 1250 ℃ | 28~31 | Bal. |

|

|

|

|

|

| Cr15Ni60 | 1150 ℃ | 15~18 | 55~61 |

| Bal. |

|

|

|

| Cr20Ni35 | 1100 ℃ | 18~21 | 34 ~ 37 |

| Bal. |

|

|

|

| TANKII APM | 1425 ℃ | 20.5~23.5 |

| 5.8 | Bal. | / |

|

|

| 0Cr27Al7Mo2 | 1400 ℃ | 26.5~27.8 |

| 6~7 | Bal. |

|

| 2 |

| 0Cr21Al6Nb | 1350 ℃ | 21~23 |

| 5~7 | Bal. |

| 0.5 |

|

| 0Cr25Al5 | 1250 ℃ | 23~26 |

| 4.5~6.5 | Bal. |

|

|

|

| 0Cr23Al5Y | 1300 ℃ | 22.5~24.5 |

| 4.2~5.0 | Bal. |

|

|

|

| 0Cr19Al3 | 1100 ℃ | 18~21 |

| 3~4.2 | Bal. |

|

|

|

Cov khoom tseem ceeb ntawm FeCrAl hlau hlau:

①Qhov kub siv yog siab, qhov kub siv ntawm cov hlau-chromium txhuas hlau hlau hauv huab cua tuaj yeem ncav cuag 1300 ℃;

② Lub neej ntev;

③Qhov kev thauj khoom saum npoo uas tso cai yog loj;

⑤Qhov hnyav tshwj xeeb me dua li cov hlau nickel-chromium; ④Qhov tsis kam oxidation zoo, thiab zaj duab xis AI2O3 tsim tom qab oxidation muaj cov tshuaj tiv thaiv zoo thiab siab resistivity;

⑥Kev tiv taus siab;

⑦Zoo tiv taus sulfur;

⑧ Tus nqi qis dua li ntawm nickel-chromium alloy;

⑨Qhov tsis zoo yog tias thaum qhov kub nce ntxiv, nws ua rau pom kev zoo, thiab lub zog ntawm qhov kub siab yog qis.

Cov yam ntxwv ntawm cov hlau nickel-chromium hluav taws xob yog:

① Muaj zog heev thaum kub siab;

② Txias tom qab siv ntev, cov khoom yuav tsis tawg yooj yim;

③Qhov emissivity ntawm tag nrho oxidized Ni-ming alloy yog siab dua li ntawm Fe-Cr-Al alloy;

④Tsis muaj hlau nplaum;

⑤Tsuas yog rau huab cua sulfur, nws muaj kev tiv thaiv corrosion zoo dua

Pawg khoom

-

Xov tooj

-

Email

-

Whatsapp

-

WeChat

Judy

150 0000 2421

-

Sab saum toj