Lub Caij Nplooj Hlav Hlev

pRoduct Piav

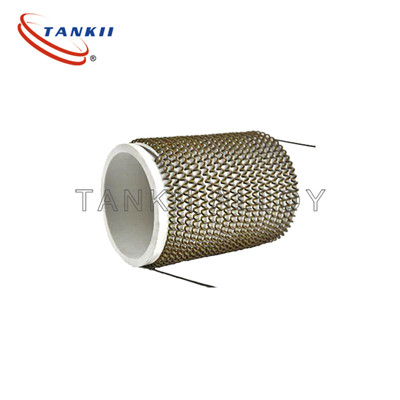

Peb lub tuam txhab tsim cov high-zoo hlau-chromium-txhuas cov xov hlau hluav taws xob cov hlau hluav taws xob, uas tau txais lub tshuab hluav taws xob cov hlau hluav taws xob, uas tau txais lub tshuab hluav taws xob cov hluav taws xob, cov khoom siv hluav taws xob kom zoo li qub winding tshuab. Cov yam ntxwv ntawm cov khoom lag luam no: cov cua kub kub, lub neej ntev, cov suab nrov me me tom qab ncab, ci thiab huv si nto; Dav siv hauv cov hluav taws xob me me, cua sov thiab cua tshuab hluav taws xob, cov tshuab hluav taws xob, cov khoom siv hluav taws xob tsis muaj zog thiab tsim khoom siv raws li cov neeg xav tau.

| Zog W | Vtheem hoom V | Lub voos voos lub cheeb | Tshooj Mm | Length (siv) hli | Wyim g |

| 300 | 220 | 0.25 | 3.7 | 122 | 1.9 |

| 500 | 220 | 0.35 | 3.9 | 196 | 4.3 |

| 600 | 220 | 0.40 | 4.2 | 228 | 6.1 |

| 800 | 220 | 0.50 | 4.7 | 302 | 11.1 |

| 1000 | 220 | 0.60 | 4.9 | 407 | 18.5 |

| 1200 | 220 | 0.70 | 5.6 | 474 | 28.5 |

| 1500 | 220 | 0.80 | 5.8 | 554 | 39.0 |

| 2000 | 220 | 0.95 | 6.1 | 676 | 57.9 |

| 2500 | 220 | 1.10 | 6.9 | 745 | 83.3 |

| 3000 | 220 | 1.20 | 7.1 | 792 | 98.3 |

Qhov ntsuas kub thiab tshuaj lom neeg ntawm cov cua kub

| Teem nqi | Max. Conti uous Kev khiav hauj lwm npau taws. | Cr% | Ni% | Ib% | FE% | Rov muaj% | Nb% | Mo% |

| Cr20NI80 | 1200 ℃ | 20 ~ 23 | Bal. |

|

|

|

|

|

| Crjni70 | 1250 ℃ | 28 ~ 31 31 | Bal. |

|

|

|

|

|

| Cr15ni60 | 1150 ℃ | 15 ~ 18 | 55 ~ 61 |

| Bal. |

|

|

|

| Cr20ni35 | 1100 ℃ | 18 ~ 21 | 34 ~ 37 |

| Bal. |

|

|

|

| Tankii APM | 1425 ℃ | 20,5 ~ 23.5 |

| 5.8 | Bal. | / |

|

|

| 0cr27al7mo2 | 1400 ℃ | 26.5 ~ 27.8 |

| 6 ~ 7 7 | Bal. |

|

| 2 |

| 0cr21al6nbb | 1350 ℃ | 21 ~ 23 |

| 5 ~ 7 | Bal. |

| 0.5 |

|

| 0CR25AL5 | 1250 ℃ | 23 ~ 26 |

| 4.5 ~ 6.5 | Bal. |

|

|

|

| 0cr23al5y | 1300 ℃ | 22.5 ~ 24.5 |

| 4.2 ~ 5.0 | Bal. |

|

|

|

| 0cr19al3 | 1100 ℃ | 18 ~ 21 |

| 3 ~ 4.2 | Bal. |

|

|

|

Cov txheej txheem tseem ceeb ntawm cov fectral alloy hlau:

Siv qhov kub thiab txias yog qhov siab, siv tau kub ntawm cov hlau-chromium aluminium alloy hlau nyob rau hauv cov cua tuaj yeem ncav cuag 1300 ℃;

②long service lub neej;

③THTHYE RAWS LI LUB CAIJ NTUJ CEEB TOOM yog loj;

⑤THE Cov ntiajteb txawj nqus me me yog me dua li tus npib tsib xee-chromium alloy; ④the oxidation tsis kam yog qhov zoo, thiab cov yeeb yaj kiab Ai2o3 tau tsim tom qab oxidation muaj cov tshuaj tsis kam zoo thiab muaj kev tiv thaiv zoo;

⑥hligh resisticity;

⑦good sulphur kuj;

Tus nqi yog qis dua li ntawm Nickel-chromium alloy;

Qhov tsis zoo yog qhov ntsuas kub uas nce ntxiv, nws ua kom muaj zog yooj yim, thiab lub zog ntawm qhov kub siab yog tsawg.

Cov yam ntxwv ntawm Nickel-Chromium Hluav Taws Xob Hluav Taws Xob yog:

① Lub zog siab ntawm qhov kub;

②cool cia tom qab kev siv ntev, cov khoom yuav tsis ua nkig;

Kev ua emissivity ntawm tag nrho oxidized ni-ming alloy yog siab tshaj qhov ntawm Fe-Al Alloy;

InoKo Magnetism;

⑤excepten rau cov txiv lws suav, nws muaj kev tiv thaiv corrosion zoo dua